D630 X2

En tant que plus puissante raboteuse de la gamme Robland, la D630 X2 se situe au sommet de notre série Apex - des machines où aucune dépense n'est épargnée pour offrir des performances, un confort et une convivialité inégalés. Conçue pour les professionnels qui n'exigent rien d'autre que le meilleur, la D630 X2 associe une puissance brute à des fonctions avancées, notamment le contrôle numérique via l'écran tactile caractéristique de Robland, ce qui rend les travaux les plus difficiles plus faciles et plus efficaces.

Pesant deux fois plus que la D510, la D630 X2 offre des capacités infinies pour manipuler les matériaux les plus lourds et les plus exigeants. Cette masse supplémentaire garantit une stabilité et des performances optimales, même sous les charges de travail les plus intenses.

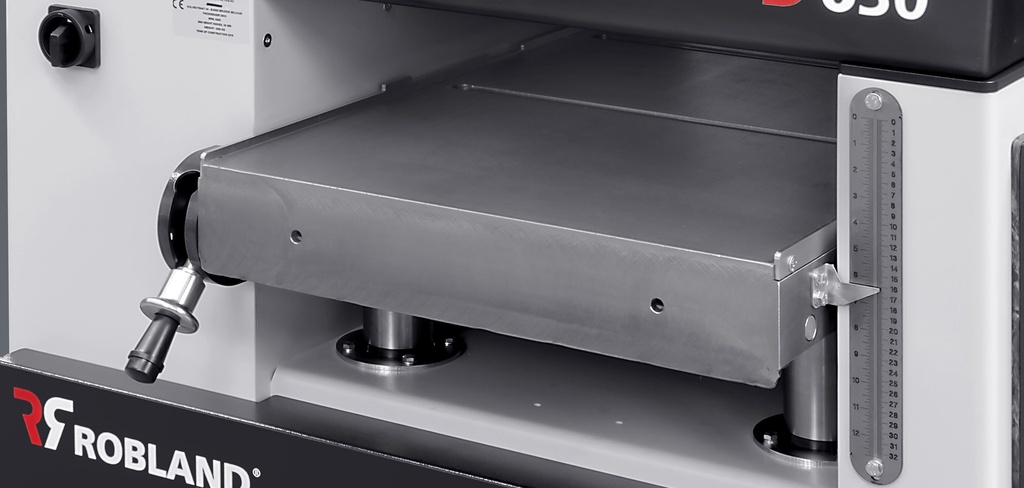

Avec une vitesse d'alimentation variable allant de 5 à 22 m/min, la D630 X2 s'adapte sans effort à une grande variété de tâches, vous donnant un contrôle total sur le rythme de votre travail. La table de rabotage massive et ultra stable est déplacée avec une précision numérique, contrôlée par l'écran tactile Robland, permettant des réglages précis qui garantissent des résultats parfaits à chaque fois.

La profondeur de coupe maximale de 8 mm souligne la capacité de la D630 X2 à traiter facilement les matériaux les plus grands et les plus durs. Pour les professionnels qui recherchent le plus haut niveau de performance en matière de rabotage, combiné à la toute dernière technologie de commande numérique, la D630 X2 représente le summum absolu de l'ingénierie Robland, offrant des possibilités illimitées et les meilleurs résultats pour chaque projet.

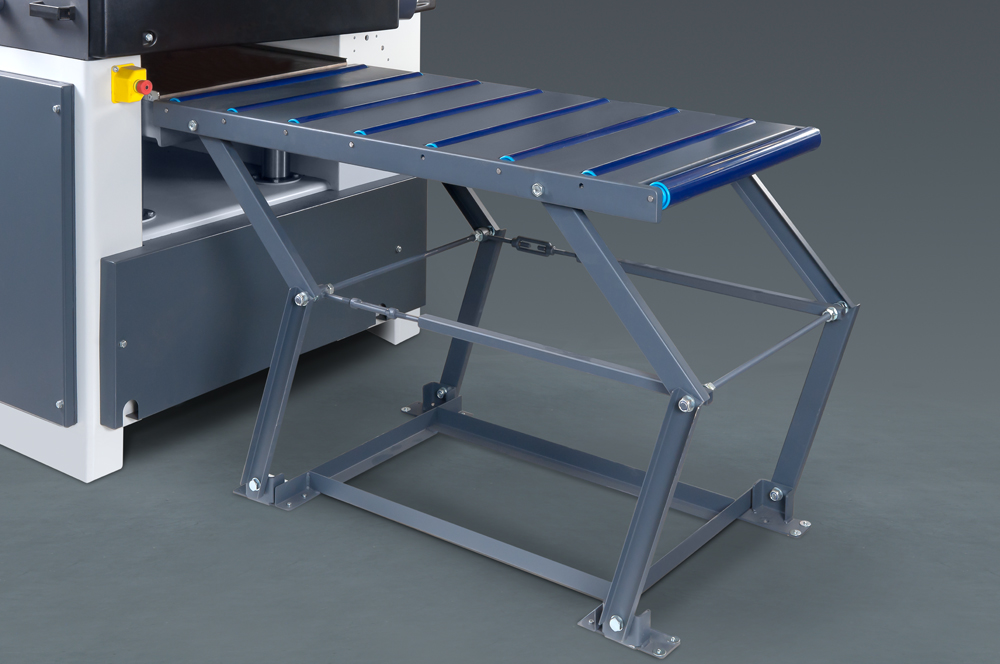

As the most powerful thicknesser in the Robland lineup, the D630 X2 sits at the top of our Apex series—machines where no expense is spared in delivering unmatched performance, comfort, and user-friendly operation. Engineered for professionals who demand nothing but the best, the D630 X2 combines raw power with advanced features, including numerical control via Robland's signature touchscreen, making even the toughest jobs easier and more efficient. Weighing twice as much as the D510, the D630 X2 offers endless capabilities for handling the heaviest and most demanding materials. This added mass ensures optimal stability and performance, even under the most intense workloads. With a variable feeder speed ranging from 5 to 22 m/min, the D630 X2 adapts effortlessly to a wide variety of tasks, giving you complete control over the pace of your work. The massive, ultra-stable thicknesser table is moved with numerical precision, controlled through the Robland touchscreen, allowing for fine-tuned adjustments that guarantee perfect results every time. The 8 mm maximum depth of cut underscores the D630 X2's ability to handle the largest and toughest materials with ease. For professionals seeking the highest level of thicknessing performance combined with the latest in numerical control, the D630 X2 represents the absolute top tier of Robland engineering, delivering limitless possibilities and the best results in every project.

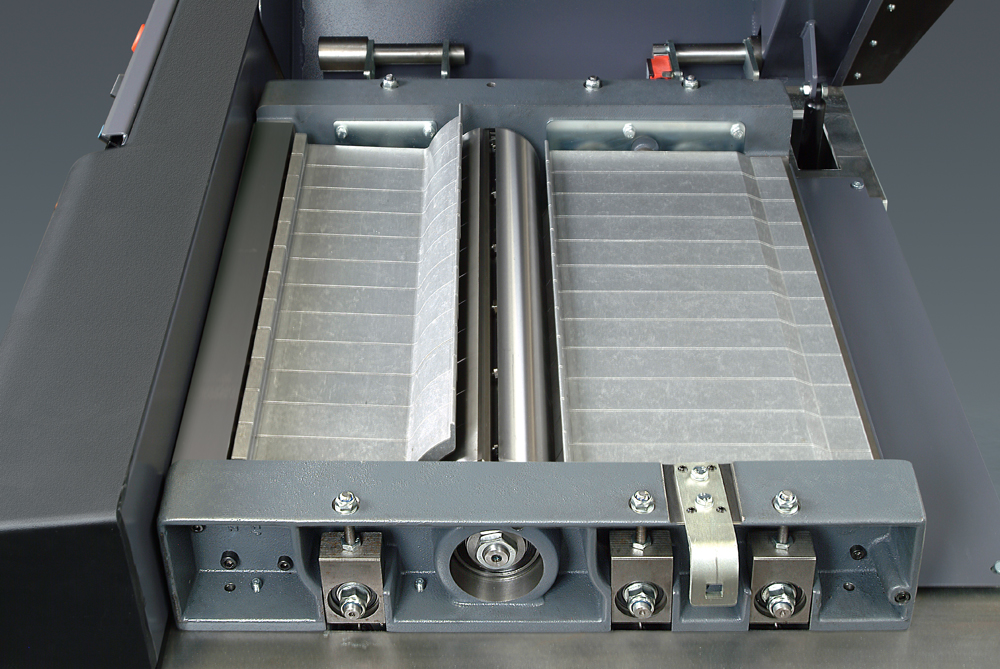

Puissance silencieuse sur bois dur : bloc de coupe en spirale

La raboteuse peut en option également être équipée d'un bloc de coupe hélicoïdal, conçu pour un travail du bois en souplesse et plus silencieux. Ce bloc de coupe innovant comporte une série de petits couteaux rectangulaires disposés en spirale, ce qui garantit que chaque couteau travaille de manière incrémentielle pour un processus de coupe fluide et efficace. Il en résulte une réduction significative du bruit et une finition plus fine des bois durs.

Cependant, le bloc de coupe en spirale n'est pas recommandé pour les bois tendres comme le pin, en raison de deux facteurs clés :

Teneur en résine : Les résineux ont tendance à avoir une teneur plus élevée en résine, qui peut s'encrasser et affecter les performances du bloc de coupe.

Texture fibreuse : La nature fibreuse des bois tendres comme le pin peut entraîner des déchirures ou des flous, ce qui réduit la qualité générale de la finition.

Pour ceux qui travaillent principalement avec des bois durs, le bloc de coupe en spirale est une excellente amélioration, offrant des performances accrues et une finition supérieure.

Solide Table en Fonte

Résistance Supérieure avec Structure en Nid d'Abeille

Nos tables en fonte sont conçues pour une durabilité et des performances exceptionnelles. Dotées d'une structure robuste en nid d'abeille, ces tables offrent le meilleur rapport résistance/poids, garantissant un support fiable sans encombrement inutile.

Double Rabotage pour une Qualité Optimale

Chaque table est soumise à un processus de rabotage méticuleux en étapes pour garantir les plus hauts standards de qualité Robland. Ces tables sont fabriquées à partir de fonte belge de première qualité ; le processus de rabotage est effectué en interne pour maintenir un contrôle qualité strict :

- Rabotage Initial : La table est rabotée pour obtenir une planéité parfaite, créant une surface stable et uniforme. Cet enlèvement délicat de matière entraîne une dissipation d'énergie minimale et limitent ainsi tout risque de déformation.

- Réduction de la friction: signature Robland : La dernière étape consiste à créer des micro-rainures améliorant ainsi la précision et la facilité de glissement des pièces en bois sur la table en fonte.

- Signature Microgrooves:

Précision améliorée grâce à la technologie Microgroove

Notre technologie à micro-rainures est la marque distinctive de nos tables en fonte. Ces rainures finement travaillées permettent un glissement du bois sans effort, minimisant la résistance et assurant une précision maximale lors des opérations de coupe.

Commande avancée avec l'écran tactile Robland

La D630 X2 est la version numérique de la D630 EL, offrant un contrôle avancé via l'interface tactile caractéristique de Robland. Cette mise à niveau remplace la commande électrique traditionnelle de la table de rabotage par un écran tactile moderne et intuitif. Conçu dans un souci de convivialité et de productivité, l'écran permet des réglages précis et une utilisation aisée, rationalisant ainsi l'ensemble du processus de rabotage..

Avec le D630 X2, les opérateurs bénéficient d'un meilleur contrôle, ce qui simplifie les tâches les plus exigeantes et les rend plus efficaces, tout en garantissant des résultats optimaux avec un minimum d'efforts.

CARACTÉRISTIQUES

General

Planer-Thicknesser

VITESSE

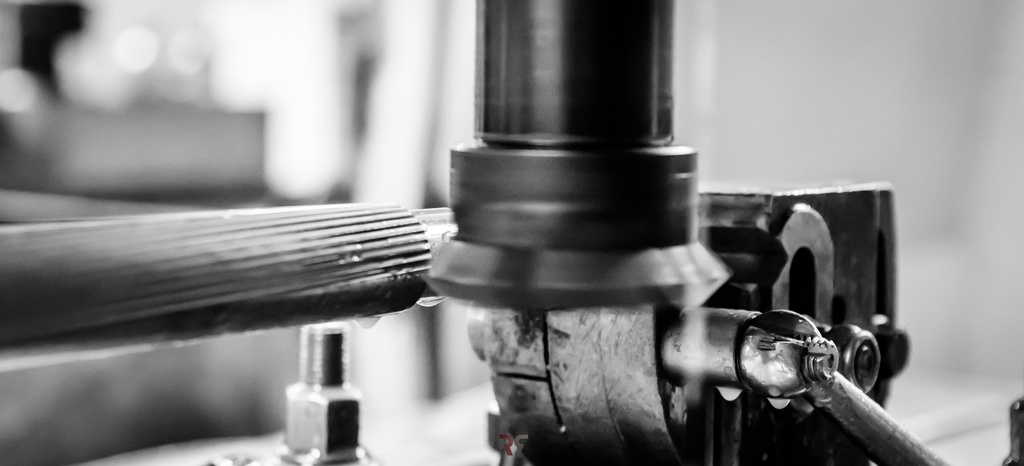

Production belge rapide avec des fournisseurs européens de confiance.

Concentration sur le temps et la qualité plutôt que sur les coûts.

Une chaîne d'approvisionnement courte réduit les temps d'attente et améliore l'efficacité.

DURABILITÉ

Pièces de rechange disponibles à vie.

Production responsable pour un impact environnemental minimal.

Focus sur des composants robustes et fiables.

SIMPLICITÉ

Des conceptions conviviales favorisant l’efficacité.

Des commandes simples avec une interface claire garantissent un fonctionnement fluide sans fonctionnalités inutiles.

Montage et entretien faciles