KT30 PRO

The KT30 PRO is the more powerful sibling of the KT30, designed for enhanced performance and versatility. Featuring a robust 5 HP motor, this machine offers spindle speeds ranging from 3,000 to 10,000 RPM, making it capable of handling a wide range of tasks with precision. The spindle can rotate both clockwise and counterclockwise, allowing for counter milling, which adds another layer of flexibility to your operations. Additionally, the KT30 PRO is equipped with an electrical brake module, making it safer and more effective when using larger, heavier tools. This combination of power, speed, and advanced features makes the KT30 PRO the ideal choice for professionals seeking a high-performance spindle moulder.

The KT30 PRO is the more powerful sibling of the KT30, designed for enhanced performance and versatility. Featuring a robust 5 HP motor, this machine offers spindle speeds ranging from 3,000 to 10,000 RPM, making it capable of handling a wide range of tasks with precision. The spindle can rotate both clockwise and counterclockwise, allowing for counter milling, which adds another layer of flexibility to your operations. Additionally, the KT30 PRO is equipped with an electrical brake module, making it safer and more effective when using larger, heavier tools. This combination of power, speed, and advanced features makes the KT30 PRO the ideal choice for professionals seeking a high-performance spindle moulder.

HIGHLIGHTED FEATURES

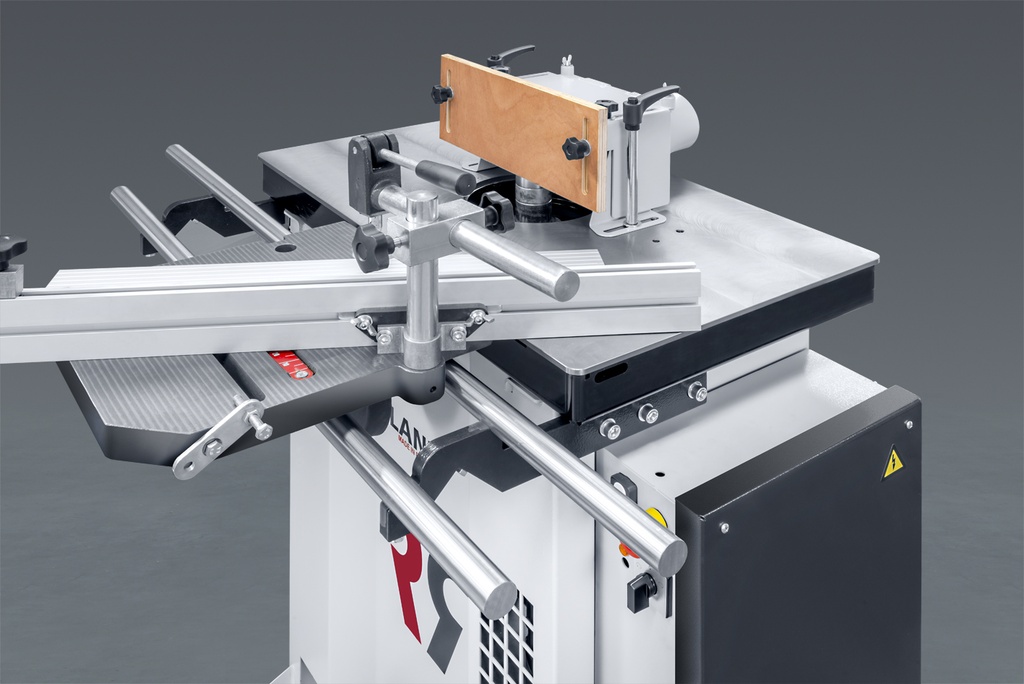

Heavy Steel Table for Optimal Support

The small spindle moulder is built with a heavy steel table, providing unmatched stability and support when working with the machine. This robust table ensures precision and durability, even during heavy-duty operations. Designed with pre-drilled holes for easy feeder mounting, it allows for hands-free operation, increasing efficiency and ease of use. Proudly produced in-house on our CNC machines in Belgium, this steel table reflects our commitment to local craftsmanship and high-quality production from start to finish.

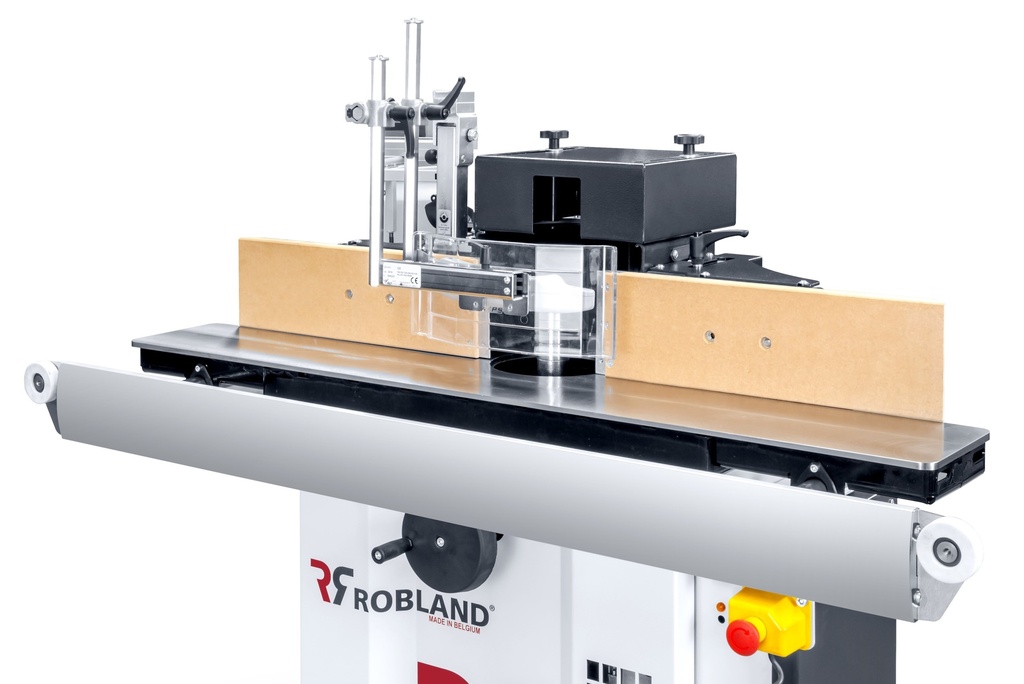

Advanced 3D-Printed Featherboards for Enhanced Safety

The small spindle moulder supports the use of our own 3D-printed featherboards, providing an extra layer of safety, particularly when working with smaller workpieces. These featherboards are designed with a durable PLA body for strength and stability, while the TPU downpressers offer flexibility and a secure hold on your workpiece.

Easily replaceable TPU components allow for simple maintenance, ensuring long-term effectiveness. By keeping your hands safely away from the cutting area, these featherboards provide greater control and precision during operations.

Table Extensions for Handling Larger Workpieces

The small spindle moulder can be fitted with table extensions, significantly increasing the machine’s length and width. This feature allows you to work comfortably with larger pieces of wood, enhancing the versatility of the machine. By expanding the work surface, these extensions provide additional support and stability for oversized projects, making the spindle moulder suitable for a broader range of woodworking tasks.

CARACTÉRISTIQUES

General specifications

Spindle

VITESSE

Production belge rapide avec des fournisseurs européens de confiance.

Concentration sur le temps et la qualité plutôt que sur les coûts.

Une chaîne d'approvisionnement courte réduit les temps d'attente et améliore l'efficacité.

DURABILITÉ

Pièces de rechange disponibles à vie.

Production responsable pour un impact environnemental minimal.

Focus sur des composants robustes et fiables.

SIMPLICITÉ

Des conceptions conviviales favorisant l’efficacité.

Des commandes simples avec une interface claire garantissent un fonctionnement fluide sans fonctionnalités inutiles.

Montage et entretien faciles