HX260

De Robland HX260 is onze kleinste combinatiemachine, ontworpen om ruimte efficiënt te benutten zonder in te leveren op veelzijdigheid. Deze compacte krachtpatser biedt vier standaardfuncties: zagen, frezen, schaven en vandikteschaven, alles in één machine.

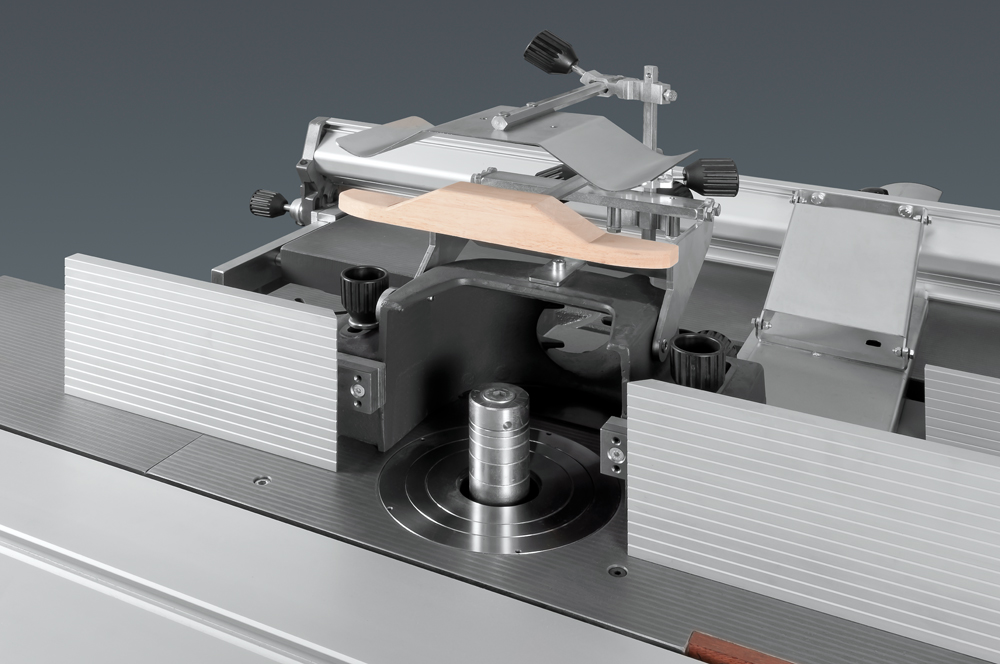

Voor nog meer functionaliteit kunnen optionele functies voor gatenboren en pennen maken worden toegevoegd, waardoor de HX260 een uiterst flexibele tool is voor elke kleine werkplaats. Ideaal voor wie optimaal gebruik wil maken van beperkte ruimte, levert de HX260 krachtige prestaties voor uiteenlopende houtbewerkingsklussen, allemaal in één efficiënte machine.

De Robland HX260 is onze kleinste combinatiemachine, ontworpen om ruimte efficiënt te benutten zonder in te leveren op veelzijdigheid. Deze compacte krachtpatser biedt vier standaardfuncties: zagen, frezen, schaven en vandikteschaven, alles in één machine. Voor nog meer functionaliteit kunnen optionele functies voor gatenboren en pennen maken worden toegevoegd, waardoor de HX260 een uiterst flexibele tool is voor elke kleine werkplaats. Ideaal voor wie optimaal gebruik wil maken van beperkte ruimte, levert de HX260 krachtige prestaties voor uiteenlopende houtbewerkingsklussen, allemaal in één efficiënte machine.

HIGHLIGHTED FEATURES

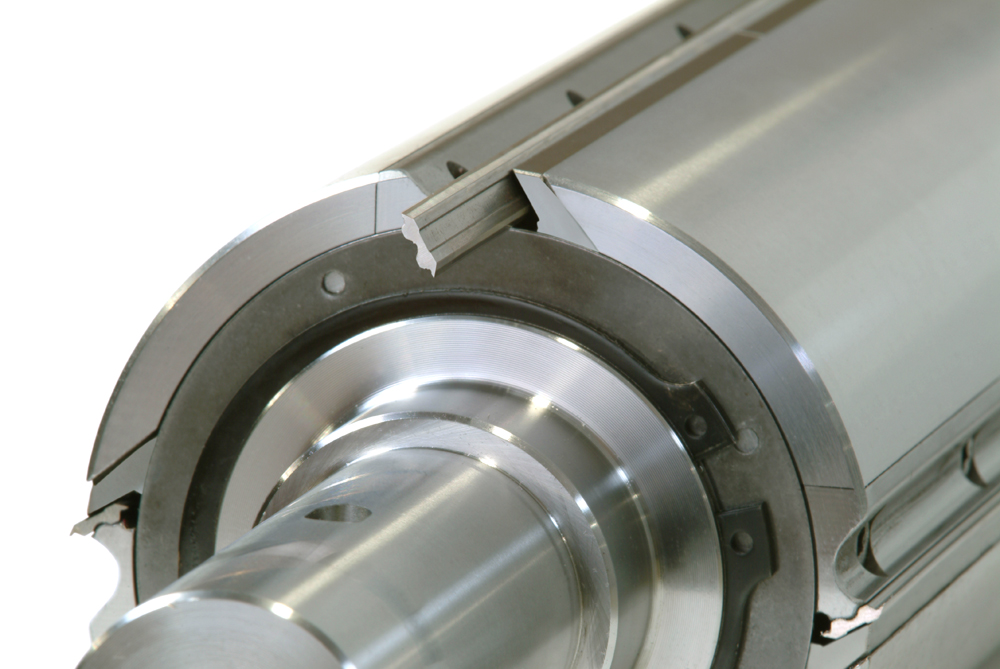

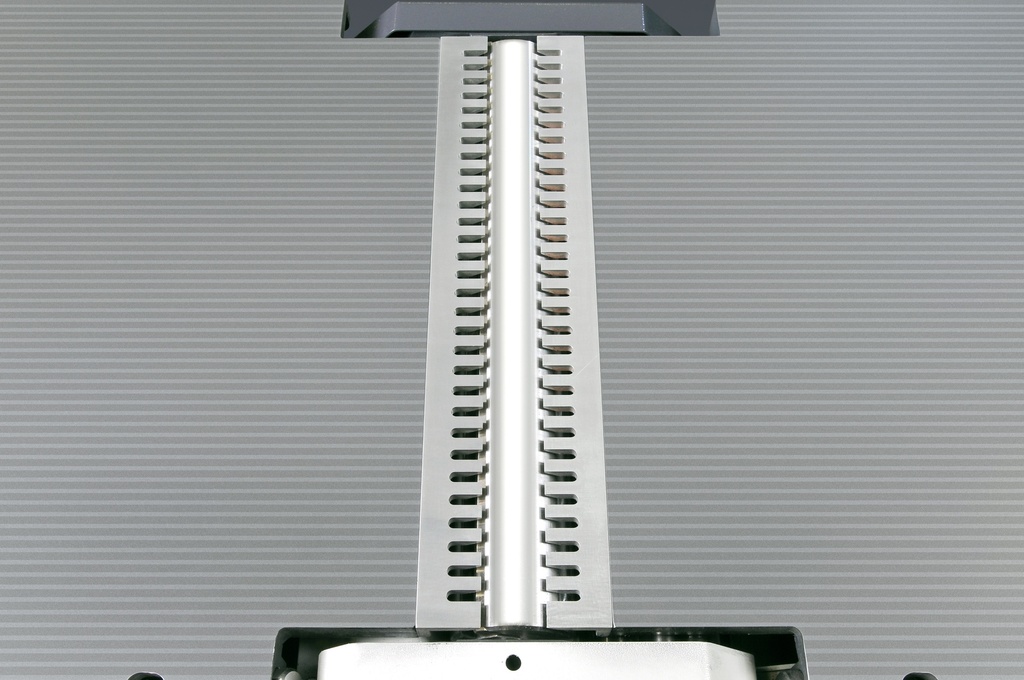

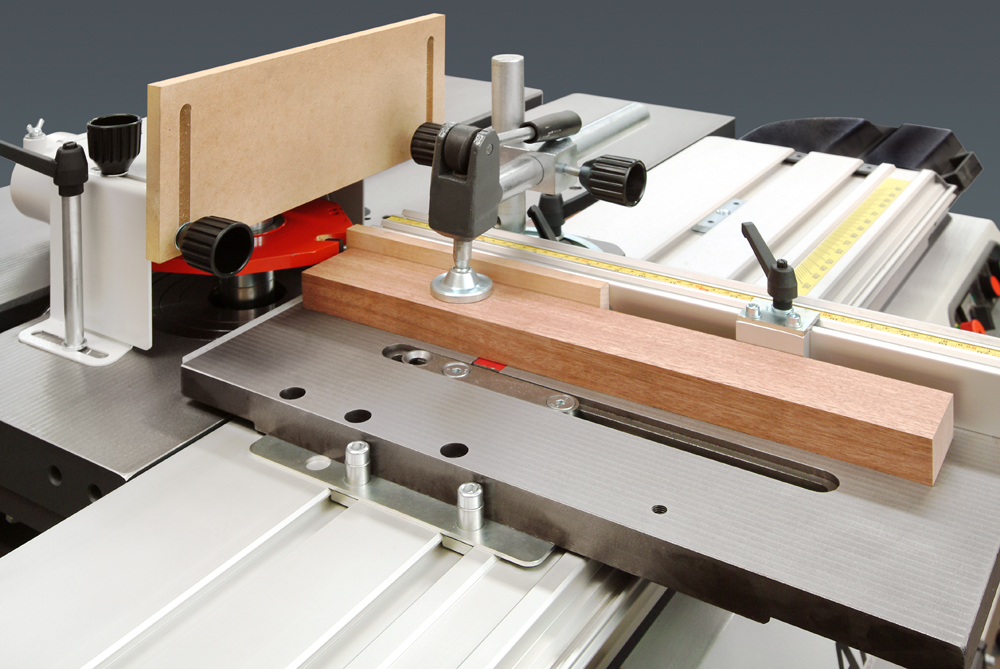

Belgian Cast Iron Tables

Superior Strength with Honeycomb Structure

Our Cast Iron Tables are engineered for exceptional durability and performance. Featuring a robust honeycomb structure, these tables provide the best strength-to-weight ratio, ensuring reliable support without unnecessary bulk.

Triple-Planed for Optimal Quality

Each table undergoes a meticulous three-step planing process to ensure the highest standards of Robland Quality. Crafted from premium Belgian cast iron, the planing process is conducted in-house to maintain strict quality control:

- Initial Planing: The table is planed to achieve perfect flatness, creating a stable and even surface.

- Friction Reduction: The second step involves further planing to reduce friction, ensuring smooth operation during use.

- Signature Microgrooves: The final step introduces our signature microgrooves. This delicate removal of material results in minimal energy dissipation, enhancing the precision and ease of movement for wooden workpieces.

Enhanced Precision with Microgroove Technology

Our microgroove technology is the hallmark of our cast iron tables. These finely crafted grooves allow for effortless gliding of wood, minimizing resistance and ensuring maximum precision during cutting operations. The result is a table surface that not only supports high accuracy but also significantly reduces the effort required in handling materials.

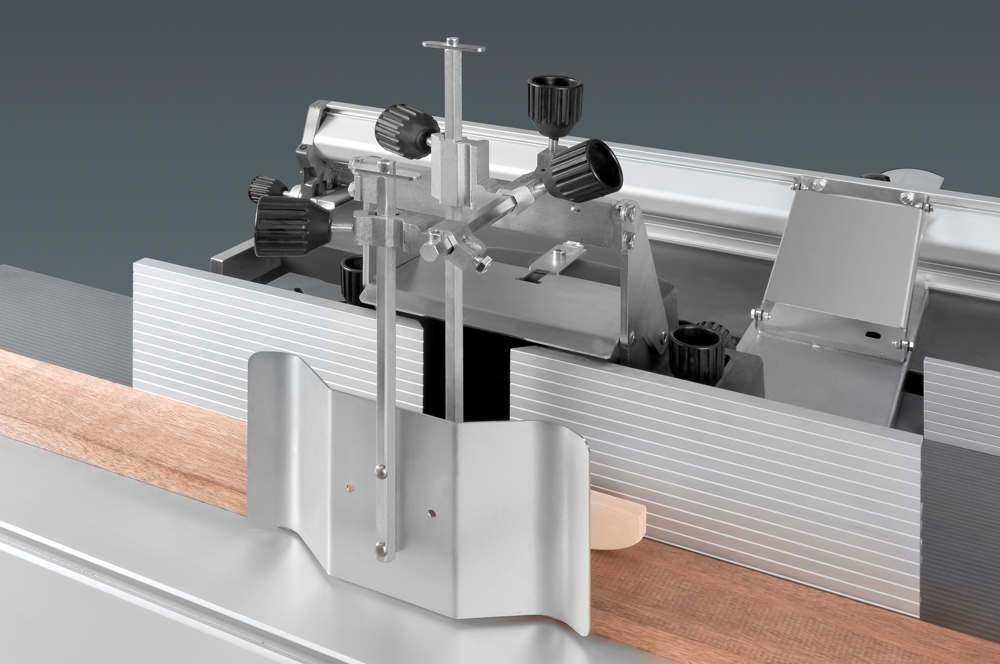

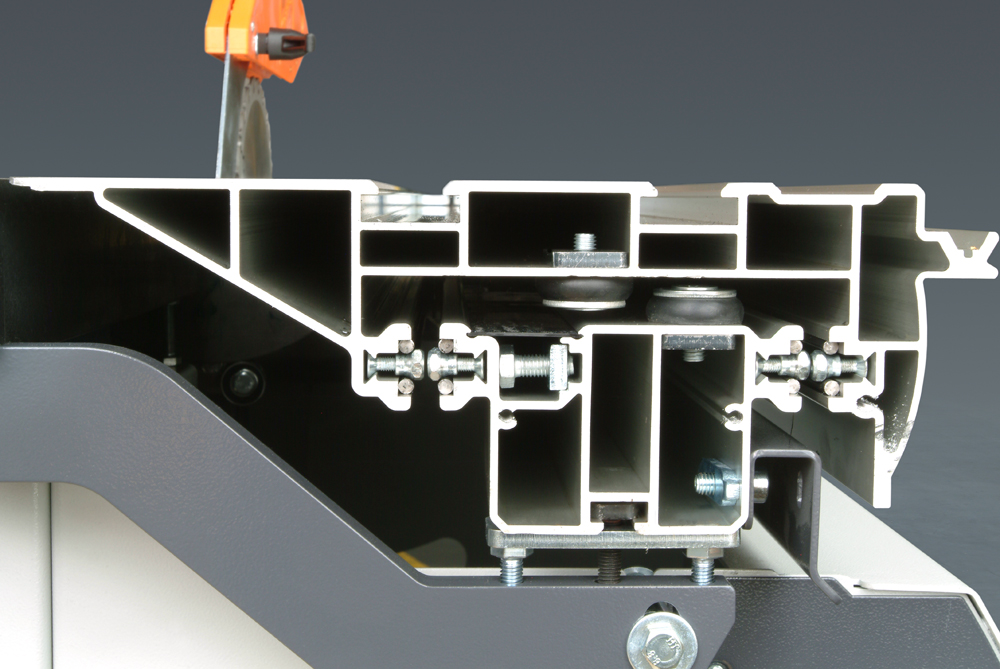

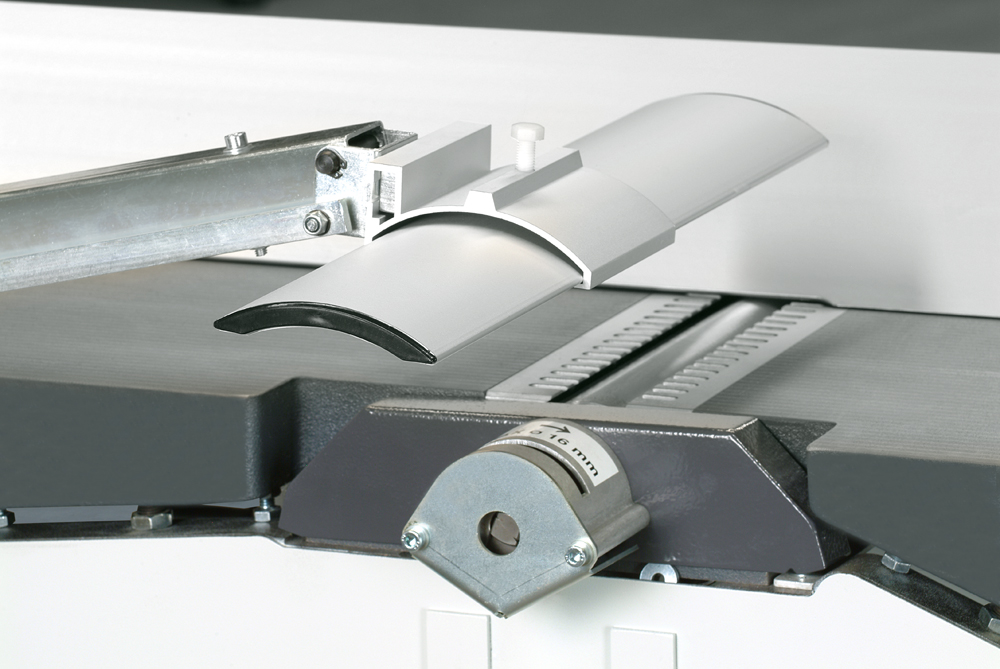

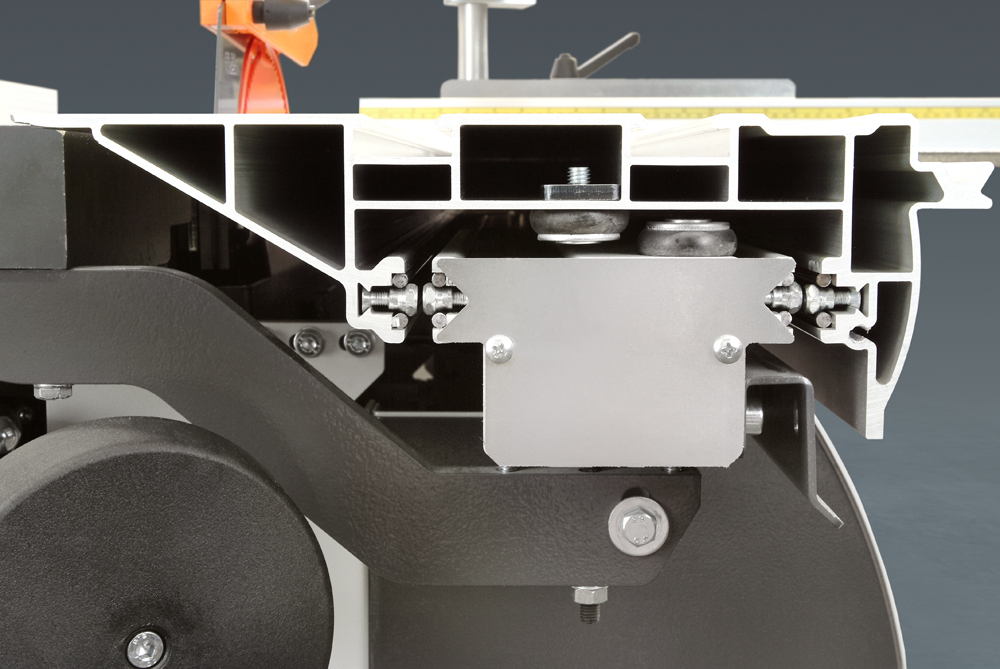

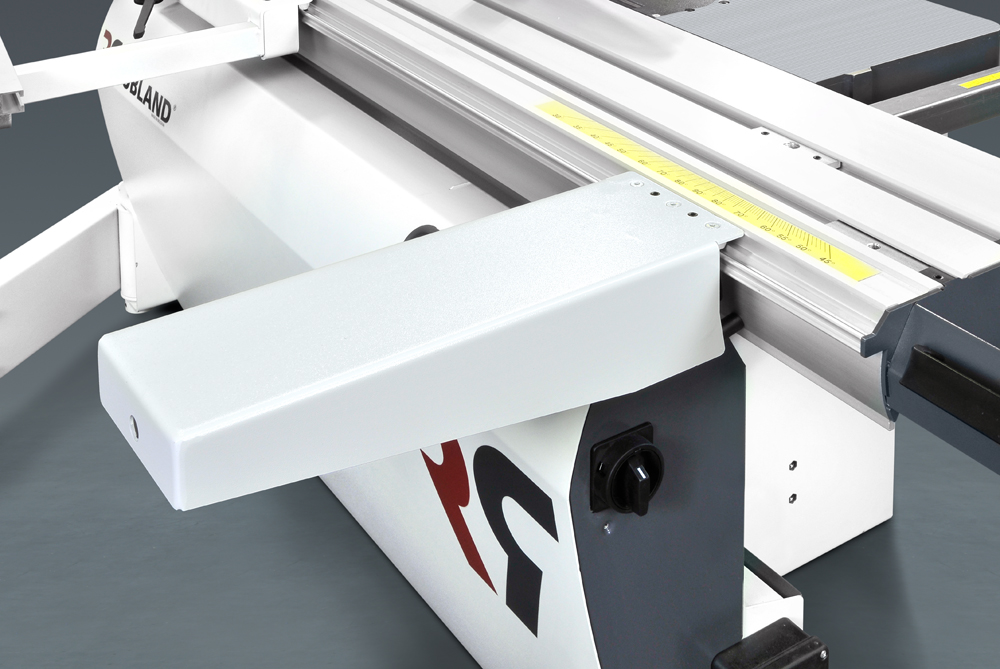

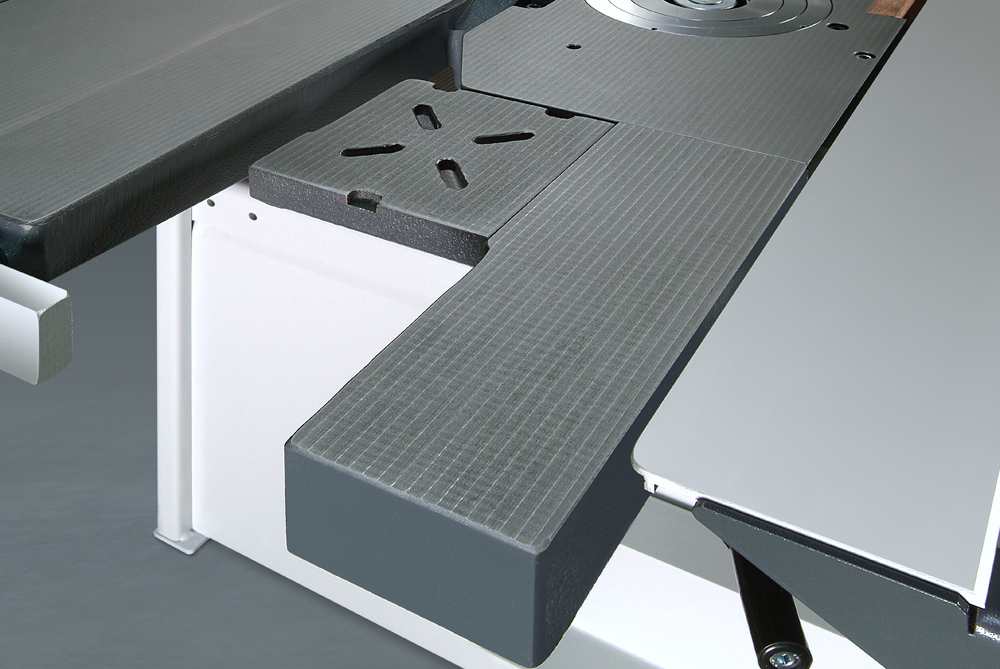

BOSS Sliding table

Revolutionary Design for Unmatched Precision

The BOSS Sliding Table System is built around our groundbreaking Balls On Solid Steel (BOSS) design, delivering the highest level of smoothness and accuracy. This advanced system ensures that every movement of the carriage is effortless and precise, making it an essential feature for achieving exceptional results in woodworking.

Frictionless Carriage Movement

Hardened steel balls glide seamlessly along solid steel shafts, creating a frictionless operation that guarantees precise and smooth movement. This innovative design minimizes resistance, allowing for easy and accurate adjustments, even under heavy loads.

Low-Maintenance Cleanliness

To ensure the system remains in optimal condition, replaceable cleaning sponges are installed at each end of the sliding table. These sponges effectively remove dust and debris from the shafts, maintaining the cleanliness of the system with minimal upkeep. This feature ensures that the BOSS Sliding Table System remains consistent and reliable, offering years of effortless operation.

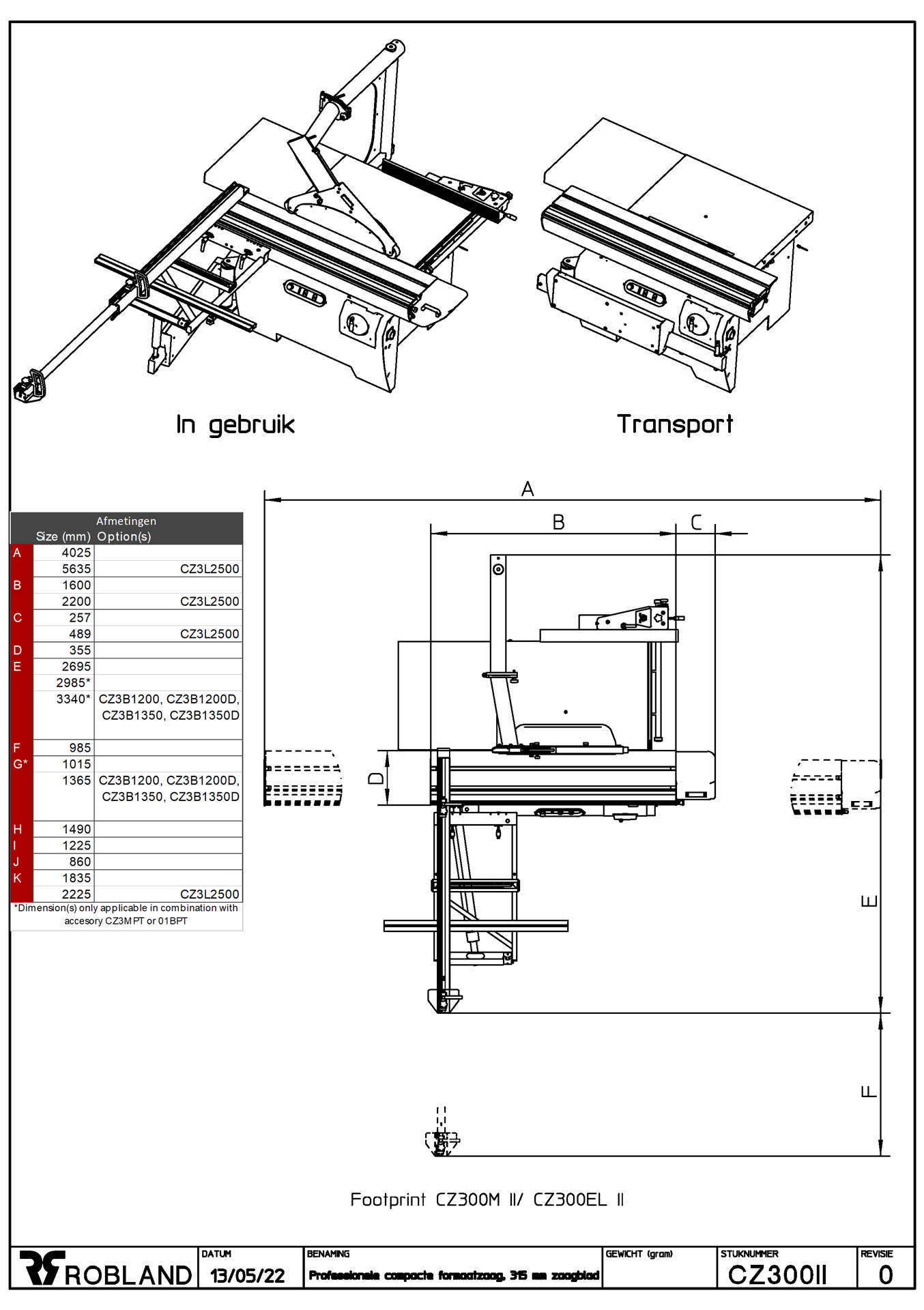

Five Operations in Just 1.5 Square Meters!

The Robland HX 260 is designed for maximum efficiency in minimal space. With a footprint of less than 1.5 square meters, this powerhouse machine delivers five essential woodworking operations: sawing, milling, planing, thicknessing, and more—all in one compact unit.

Unmatched Compactness

The HX 260 offers the functionality of a complete woodworking shop in an incredibly compact design, making it the perfect choice for workshops where space is at a premium.

Seamless Changeovers

Effortlessly switch between operations with the HX 260’s user-friendly design. Changeovers are quick and easy, allowing you to move from sawing to milling, planing, or thicknessing in no time—keeping your workflow smooth and uninterrupted.

Full Workshop Capability

Despite its small size, the HX 260 delivers powerful performance across all its functions, providing the versatility you need for any project.

SPECIFICATIES

Algemene kenmerken

Zaagafmetingen

Spil

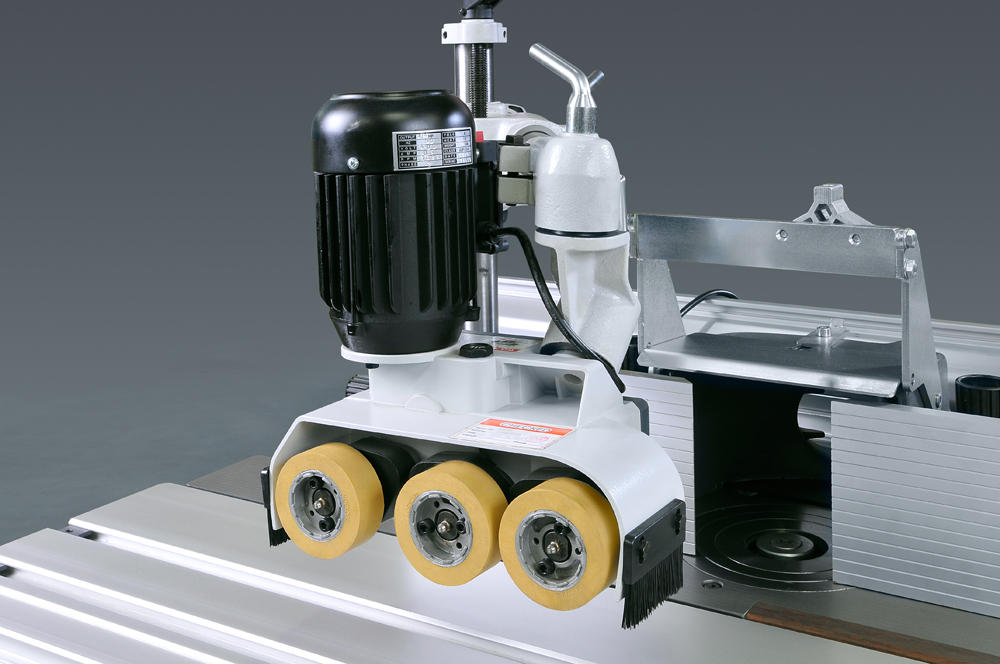

Vlak-vandiktebank

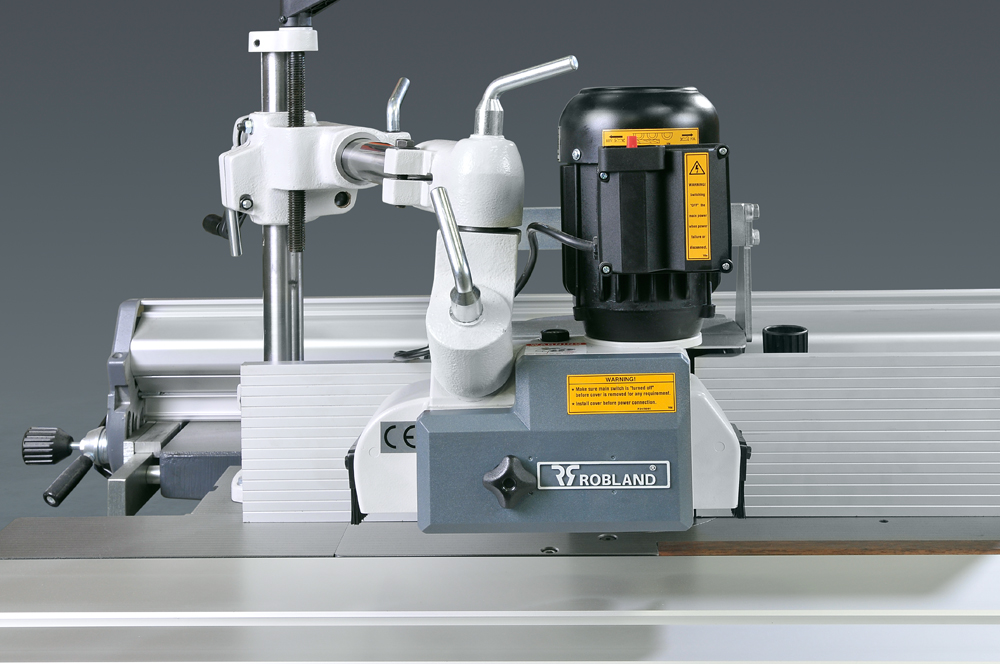

Langgatboor (optioneel)

SPEED

Fast Belgian production with trusted European suppliers.

Focus on time and quality instead of costs.

Short supply chain reduces wait times and boosts efficiency.

SUSTAINABILITY

Lifetime spare parts

Responsible production for minimal environmental impact.

Focus on robust, reliable components

SIMPLICITY

User-friendly designs promoting efficiency.

Simple controls with a clear interface ensure smooth operation without unnecessary features.

Easy assembly and maintenance