BM 3000

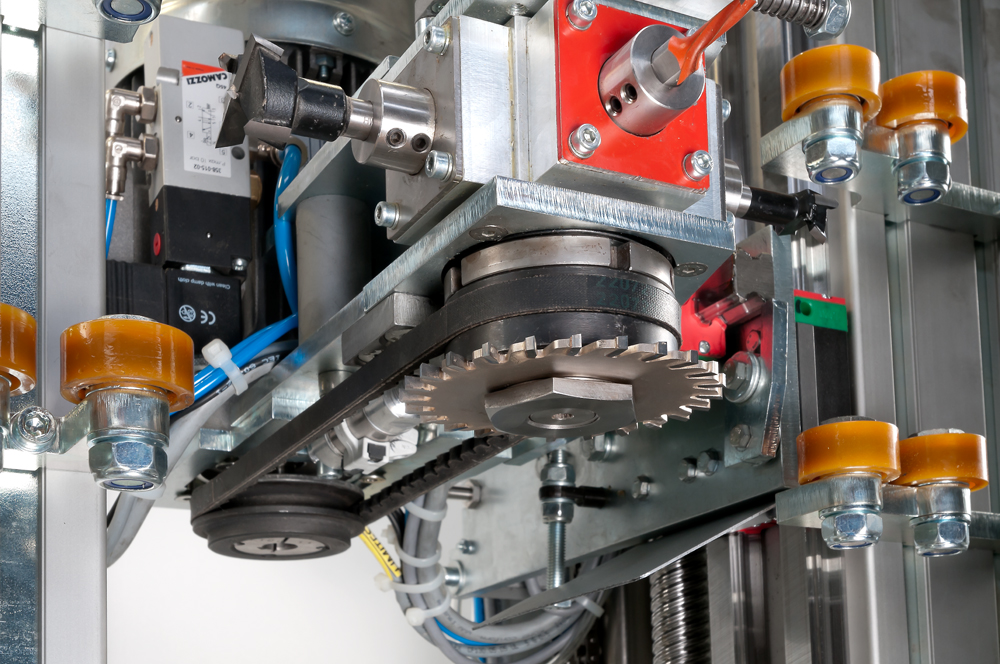

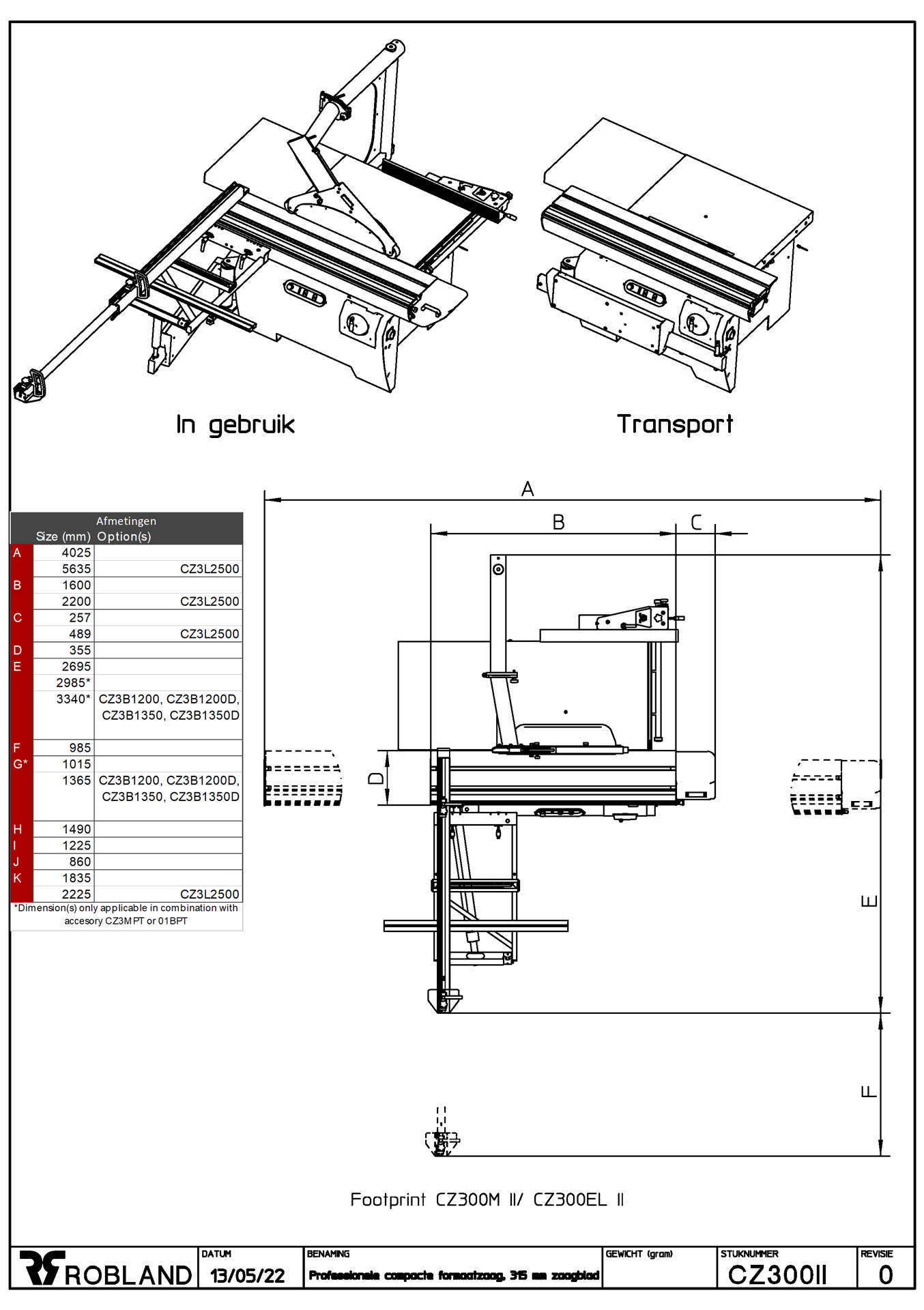

La BM 3000 est la perceuse à commande numérique de Robland, conçue comme une solution CNC de départ pour les ateliers qui cherchent à augmenter leur productivité sans sacrifier l'espace au sol. Construite autour des valeurs fondamentales de Robland que sont la vitesse, la simplicité et la durabilité, la BM 3000 offre une efficacité impressionnante tout en conservant un faible encombrement, grâce à sa conception CNC verticale, parfaite pour les ateliers disposant d'un espace limité.

Vitesse

La BM 3000 accélère considérablement votre production, en particulier dans les flux de travail à faible volume et à grande variété. Elle gère efficacement un large éventail de tâches, ce qui la rend idéale pour les ateliers qui ont besoin de flexibilité sans compromettre la vitesse.

Simplicité

Conçue dans un souci de simplicité, la BM 3000 est dotée d'un système de commande intuitif qui facilite son utilisation sans nécessiter de connaissances avancées en CAO/DAO. Après une formation de 4 heures, les opérateurs auront les compétences nécessaires pour faire fonctionner la machine, et auront appris des raccourcis, des conseils et des astuces pour maximiser la productivité.

Conception compacte

L'un des principaux avantages de la conception verticale de la CNC est son faible encombrement. Contrairement aux machines traditionnelles, la BM 3000 ne nécessite qu'un minimum d'espace au sol, ce qui la rend idéale pour les petits ateliers qui souhaitent passer à la technologie CNC sans avoir besoin de beaucoup d'espace.

Durabilité et fiabilité

Fidèle aux normes de Robland, la BM 3000 est conçue pour une fiabilité à long terme et bénéficie de l'assistance après-vente de Robland. C'est le choix idéal pour les ateliers qui cherchent à s'agrandir tout en gérant une variété de tâches, le tout dans un espace compact.

Pour ceux qui sont prêts à entrer dans la technologie CNC, la BM 3000 offre à un prix attractif une combinaison imbattable de performances, de facilité d'utilisation, d'économie d'espace et d'assistance fiable.

The BM 3000 is Robland's CNC-controlled drilling machine, designed as a starter CNC solution for workshops looking to boost productivity without sacrificing floor space. Built around Robland's core values of speed, simplicity, and sustainability, the BM 3000 delivers impressive efficiency while maintaining a small footprint, thanks to its vertical CNC design—perfect for workshops with limited space. Speed The BM 3000 significantly accelerates your production, especially in low-volume, high-variety workflows. It efficiently handles a wide range of tasks, making it ideal for workshops that require flexibility without compromising speed. Simplicity Designed with simplicity in mind, the intuitive control system makes the BM 3000 easy to operate without requiring advanced DXF knowledge. After a 4-hour workshop, operators will have the skills to run the machine, along with shortcuts, tips, and tricks to maximize productivity. Compact design A major advantage of the vertical CNC design is its space-saving nature. Unlike traditional machines, the BM 3000 requires minimal floor space, making it perfect for smaller workshops looking to upgrade to CNC technology without the need for significant space. Sustainability and reliability True to Robland’s standards, the BM 3000 is built for long-term reliability and backed by Robland's after-sales support. It’s the perfect choice for workshops looking to scale up while handling a variety of tasks, all within a compact footprint. For those ready to step into CNC technology, the BM 3000 offers an unbeatable combination of performance, ease of use, space efficiency, and reliable support.

Le concept vertical de la BM 3000

La conception verticale de la BM 3000 offre une efficacité exceptionnelle en termes d'espace, ce qui en fait une solution idéale pour les ateliers disposant de peu de place. Grâce à ce concept astucieux, la machine peut être placée contre le mur, ce qui permet d'optimiser l'espace au sol sans compromettre la fonctionnalité. Cette conception permet une plus grande flexibilité dans l'agencement de l'espace de travail, ce qui fait de la BM 3000 un choix pratique pour les ateliers qui cherchent à optimiser à la fois la productivité et l'espace.

Précision simplifiée : Logiciel CFAO convivial sur la BM 3000

La BM 3000 est équipée d'un logiciel CFAO convivial basé sur Windows qui rend la programmation simple et efficace. Grâce à la programmation paramétrique et à la possibilité de créer une bibliothèque d'outils personnalisable, les utilisateurs peuvent facilement adapter la machine aux besoins spécifiques de leur projet. Fidèle à la philosophie de Robland en matière de simplicité et de praticité, la BM 3000 se distingue dans son segment par son intuitivité et sa facilité d'utilisation, contrairement à de nombreux systèmes CNC complexes. La formation de base ne nécessite que quelques heures, ce qui permet aux opérateurs de maîtriser rapidement la machine et de se concentrer sur la réalisation du travail avec précision et facilité.

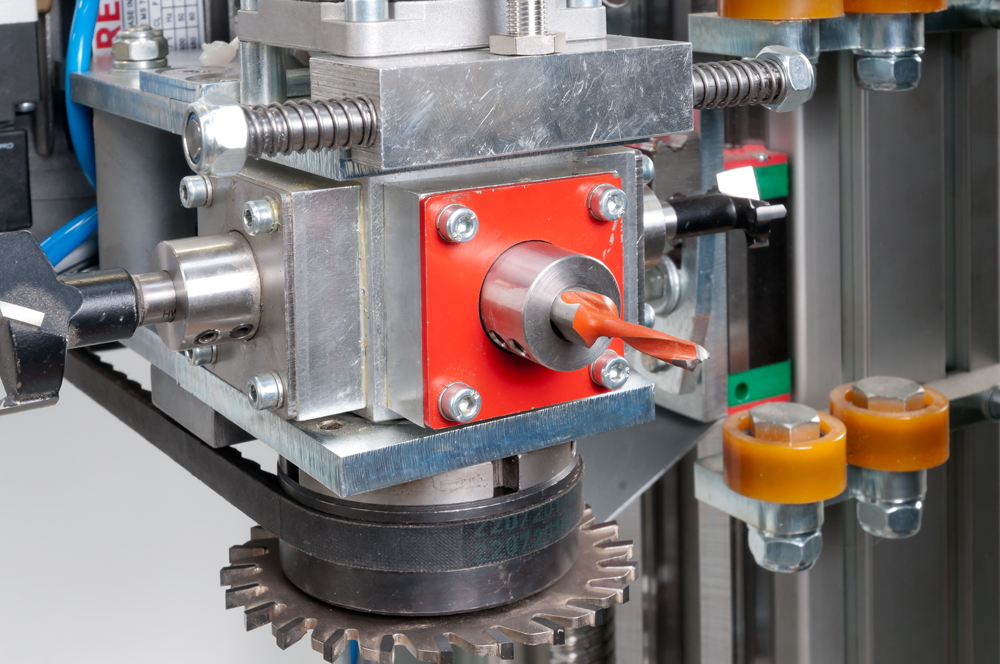

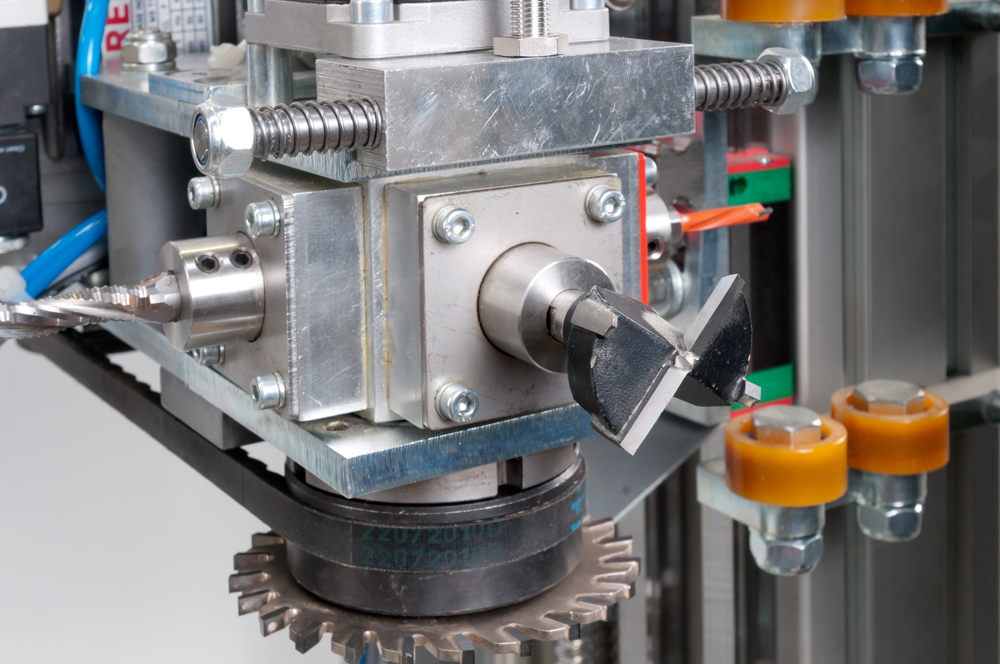

Installation des charnières sans effort : La programmation d'outils personnalisables de la BM 3000 pour un perçage de précision

La BM 3000 facilite l'installation des charnières grâce à son logiciel facile à utiliser qui vous permet de programmer et d'enregistrer les différents réglages de l'outil. Pour les applications de charnières, vous pouvez programmer sans effort la taille, la position et la profondeur de la mèche principale (mèche standard de 35 mm incluse) ainsi que les deux points ou trous latéraux. Ce niveau de personnalisation garantit un perçage précis et répétable à chaque fois, améliorant à la fois l'efficacité et la précision de vos projets de travail du bois.

CARACTÉRISTIQUES

General specifications

Tools

Workpiece

Videos

VITESSE

Production belge rapide avec des fournisseurs européens de confiance.

Concentration sur le temps et la qualité plutôt que sur les coûts.

Une chaîne d'approvisionnement courte réduit les temps d'attente et améliore l'efficacité.

DURABILITÉ

Pièces de rechange disponibles à vie.

Production responsable pour un impact environnemental minimal.

Focus sur des composants robustes et fiables.

SIMPLICITÉ

Des conceptions conviviales favorisant l’efficacité.

Des commandes simples avec une interface claire garantissent un fonctionnement fluide sans fonctionnalités inutiles.

Montage et entretien faciles