CZ400 M/EL

Découvrez la scie à panneaux compacte CZ400 M/EL — le mix ultime de la qualité de scie inégalée de Robland et de l'innovation permettant d'économiser de l'espace. Conçue pour exceller dans les petits ateliers et zones de production où chaque mètre carré compte, la CZ400 offre des coupes précises et de haute qualité dans un format réduit. Idéale pour les entreprises également équipées de grandes machines CNC, cette machine compacte vient à point pour gérer de petites séries ou des solutions rapides sans les tracas des configurations plus importantes.

Découvrez la scie à panneaux compacte CZ400 M/EL — le mix ultime de la qualité de scie inégalée de Robland et de l'innovation permettant d'économiser de l'espace. Conçue pour exceller dans les petits ateliers et zones de production où chaque mètre carré compte, la CZ400 offre des coupes précises et de haute qualité dans un format réduit. Idéale pour les entreprises également équipées de grandes machines CNC, cette machine compacte vient à point pour gérer de petites séries ou des solutions rapides sans les tracas des configurations plus importantes.

CARACTÉRISTIQUES SÉLECTIONNÉS

Table en Fonte

Résistance Supérieure avec Structure en Nid d'Abeille

Nos tables en fonte sont conçues pour une durabilité et des performances exceptionnelles. Dotées d'une structure robuste en nid d'abeille, ces tables offrent le meilleur rapport résistance/poids, garantissant un support fiable sans encombrement inutile.

Double Rabotage pour une Qualité Optimale

Chaque table est soumise à un processus de rabotage méticuleux en étapes pour garantir les plus hauts standards de qualité Robland. Ces tables sont fabriquées à partir de fonte belge de première qualité ; le processus de rabotage est effectué en interne pour maintenir un contrôle qualité strict :

- Rabotage Initial : La table est rabotée pour obtenir une planéité parfaite, créant une surface stable et uniforme. Cet enlèvement délicat de matière entraîne une dissipation d'énergie minimale et limitent ainsi tout risque de déformation.

- Microrainures : signature Robland : La dernière étape consiste à créer des micro-rainures améliorant ainsi la précision et la facilité de glissement des pièces en bois sur la table en fonte.

- Signature Microgrooves:

Précision améliorée grâce à la technologie Microgroove

Notre technologie à micro-rainures est la marque distinctive de nos tables en fonte. Ces rainures finement travaillées permettent un glissement du bois sans effort, minimisant la résistance et assurant une précision maximale lors des opérations de coupe.

Chariot Coulissant BOSS

Conception Révolutionnaire pour une Précision Inégalée

Le système de chariot coulissant BOSS est construit autour de notre conception révolutionnaire "Billes sur barres en acier" (Balls On Solid Steel : BOSS), offrant le plus haut niveau de souplesse et de précision. Ce système avancé garantit que chaque mouvement du chariot est précis et se réalise sans effort, ce qui en fait une caractéristique essentielle pour obtenir des résultats exceptionnels dans le travail du bois.

Mouvement du Chariot sans Friction

Les billes en acier trempé glissent en souplesse le long de barres en acier massif, créant un fonctionnement sans friction qui garantit un mouvement précis et fluide. Cette conception innovante minimise la résistance, permettant des réglages faciles et précis, même sous de lourdes charges.

Nettoyage Nécessitant peu d’Entretien

Pour garantir que le système reste dans un état optimal, des éponges de nettoyage remplaçables sont installées à chaque extrémité du chariot coulissant. Ces éponges éliminent efficacement la poussière et les débris des barres, maintenant ainsi la propreté du système avec un minimum d'entretien. Cette fonctionnalité garantit que le système de chariot coulissant BOSS reste cohérent et fiable, offrant des années de fonctionnement sans effort.

Agrégat de Scie en Fonte

Conçu pour l'Excellence

Au cœur de la Z400 se trouve notre engagement envers la précision et la qualité, dont presque tous les composants sont méticuleusement fabriqués en interne. L’agrégat de scie en fonte, pierre angulaire des performances de la machine, pivote sur deux coques en fonte usinées avec précision. Ce haut niveau de précision est rendu possible par notre engagement à produire nous-mêmes ces composants essentiels, garantissant que chaque Z400 répond aux normes les plus élevées de qualité et de durabilité.

Fabrication Interne Quasi-Complète

Au-delà de l'agrégat de scie, nous sommes fiers de fabriquer presque toutes les pièces de la Z400 en interne, de l'axe de scie au cadre et au-delà. Cette approche pratique nous permet de garder un contrôle complet sur le processus de production, garantissant les performances exceptionnelles qui font la réputation de nos machines. En fabriquant presque tout en interne, nous pouvons garantir que chaque composant est conçu selon des normes rigoureuses, ce qui se traduit par à une machine qui fournit des résultats fiables et de qualité professionnelle.

Collaboration avec SKF pour une Longévité Accrue des Roulements

Pour minimiser le jeu dans l'axe de la scie et garantir un fonctionnement précis, nous appliquons une force contrôlée sur nos roulements. Conscients du besoin de précision et de durabilité dans ces conditions, nous nous sommes associés à SKF pour développer un système de roulement qui prolonge la durée de vie tout en conservant la précision. Cette collaboration a abouti à une solution qui améliore les performances et la longévité de nos machines, même dans des conditions exigeantes.

Strengths

CARACTÉRISTIQUES

General specifications

Main saw blade

Scoring unit

Rip fence

Cutting length

Téléchargements

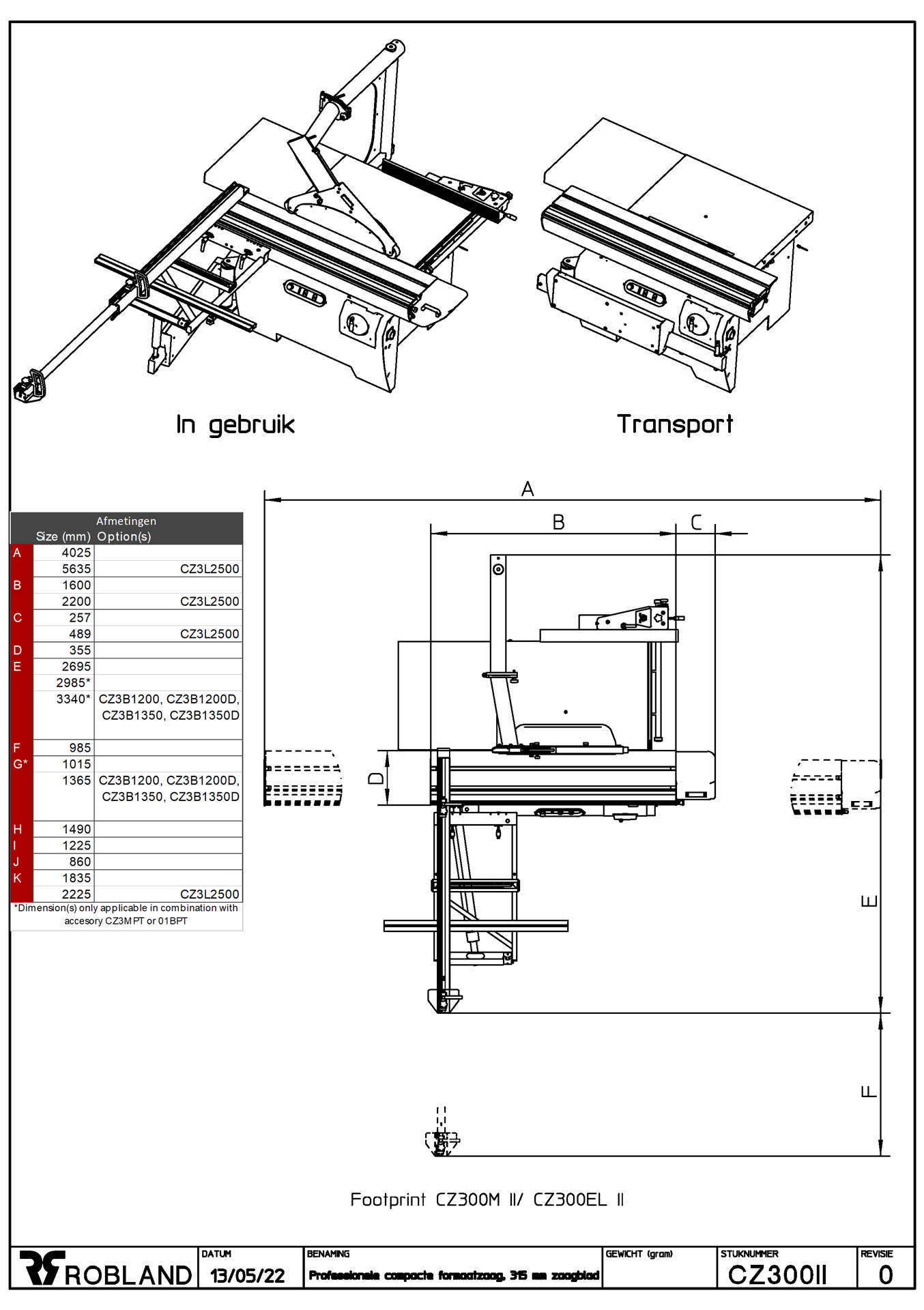

Footprints

VITESSE

Production belge rapide avec des fournisseurs européens de confiance.

Concentration sur le temps et la qualité plutôt que sur les coûts.

Une chaîne d'approvisionnement courte réduit les temps d'attente et améliore l'efficacité.

DURABILITÉ

Pièces de rechange disponibles à vie.

Production responsable pour un impact environnemental minimal.

Focus sur des composants robustes et fiables.

SIMPLICITÉ

Des conceptions conviviales favorisant l’efficacité.

Des commandes simples avec une interface claire garantissent un fonctionnement fluide sans fonctionnalités inutiles.

Montage et entretien faciles