HX TZ

The HX-TZ is the smallest saw-spindle moulder in the Robland lineup, derived from the HX series but without the planer-thicknesser. Designed for workshops with limited space, this machine excels in making the most of a small footprint. One of its biggest advantages is that it can be placed against a wall, as all operations can be accessed from the front—ideal for tight spaces.

While the HX-TZ does not support a scoring unit and its smaller sliding table isn't suited for large panel work, it is perfectly designed for precise cuts and spindle operations in smaller projects. This compact machine is perfect for woodworkers who need versatility and functionality in a space-saving design.

The HX-TZ is the smallest saw-spindle moulder in the Robland lineup, derived from the HX series but without the planer-thicknesser. Designed for workshops with limited space, this machine excels in making the most of a small footprint. One of its biggest advantages is that it can be placed against a wall, as all operations can be accessed from the front—ideal for tight spaces. While the HX-TZ does not support a scoring unit and its smaller sliding table isn't suited for large panel work, it is perfectly designed for precise cuts and spindle operations in smaller projects. This compact machine is perfect for woodworkers who need versatility and functionality in a space-saving design.

HIGHLIGHTED FEATURES

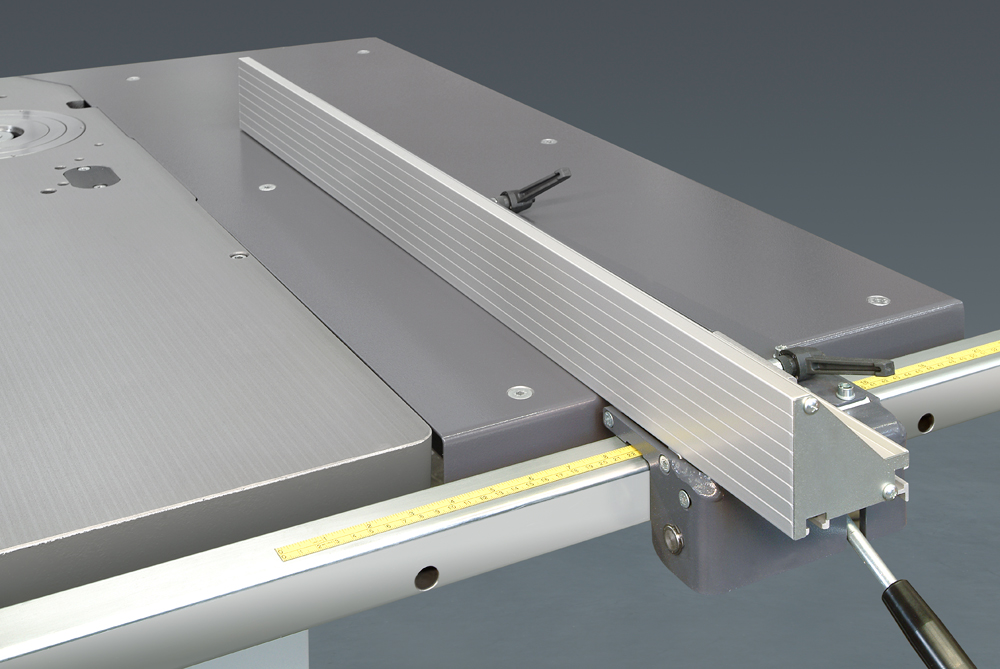

Belgian Cast Iron Tables

Superior Strength with Honeycomb Structure

Our Cast Iron Tables are engineered for exceptional durability and performance. Featuring a robust honeycomb structure, these tables provide the best strength-to-weight ratio, ensuring reliable support without unnecessary bulk.

Triple-Planed for Optimal Quality

Each table undergoes a meticulous three-step planing process to ensure the highest standards of Robland Quality. Crafted from premium Belgian cast iron, the planing process is conducted in-house to maintain strict quality control:

- Initial Planing: The table is planed to achieve perfect flatness, creating a stable and even surface.

- Friction Reduction: The second step involves further planing to reduce friction, ensuring smooth operation during use.

- Signature Microgrooves: The final step introduces our signature microgrooves. This delicate removal of material results in minimal energy dissipation, enhancing the precision and ease of movement for wooden workpieces.

Enhanced Precision with Microgroove Technology

Our microgroove technology is the hallmark of our cast iron tables. These finely crafted grooves allow for effortless gliding of wood, minimizing resistance and ensuring maximum precision during cutting operations. The result is a table surface that not only supports high accuracy but also significantly reduces the effort required in handling materials.

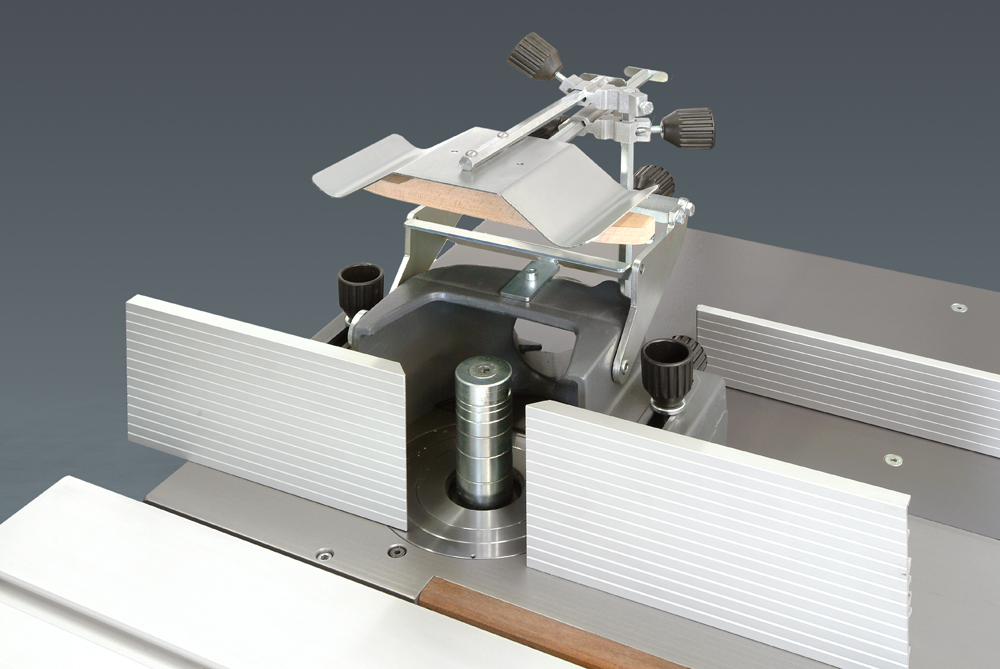

BOSS Sliding Table

Revolutionary Design for Unmatched Precision

The BOSS Sliding Table System is built around our groundbreaking Balls On Solid Steel (BOSS) design, delivering the highest level of smoothness and accuracy. This advanced system ensures that every movement of the carriage is effortless and precise, making it an essential feature for achieving exceptional results in woodworking.

Frictionless Carriage Movement

Hardened steel balls glide seamlessly along solid steel shafts, creating a frictionless operation that guarantees precise and smooth movement. This innovative design minimizes resistance, allowing for easy and accurate adjustments, even under heavy loads.

Low-Maintenance Cleanliness

To ensure the system remains in optimal condition, replaceable cleaning sponges are installed at each end of the sliding table. These sponges effectively remove dust and debris from the shafts, maintaining the cleanliness of the system with minimal upkeep. This feature ensures that the BOSS Sliding Table System remains consistent and reliable, offering years of effortless operation.

Precision-Built in Belgium

Not only is the HX-TZ designed and produced in Belgium, but the entire assembly process is also carried out with meticulous care by our skilled technicians. Every machine is built with a focus on precision, with technicians carefully measuring each individual component and the complete assembly to ensure it fits within strict tolerances.

Our teams are committed to continuous improvement, working diligently to enhance quality and reduce build times, ensuring every machine leaves our facility performing at the highest standards. The result is a machine built for durability and accuracy, reflecting the craftsmanship and dedication of Belgian manufacturing.

CARACTÉRISTIQUES

General specifications

Saw dimensions

Spindle

Téléchargements

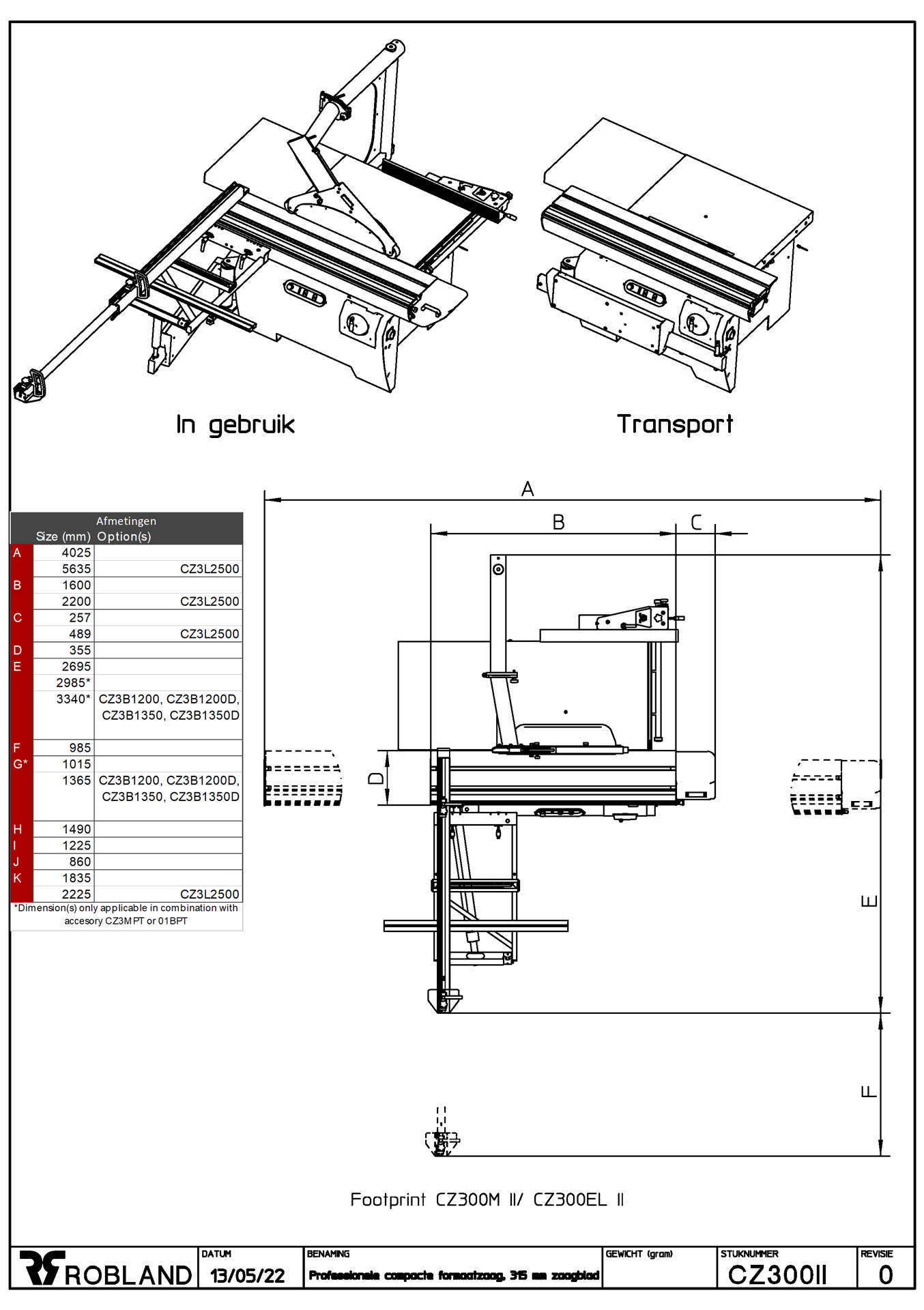

Footprint

VITESSE

Production belge rapide avec des fournisseurs européens de confiance.

Concentration sur le temps et la qualité plutôt que sur les coûts.

Une chaîne d'approvisionnement courte réduit les temps d'attente et améliore l'efficacité.

DURABILITÉ

Pièces de rechange disponibles à vie.

Production responsable pour un impact environnemental minimal.

Focus sur des composants robustes et fiables.

SIMPLICITÉ

Des conceptions conviviales favorisant l’efficacité.

Des commandes simples avec une interface claire garantissent un fonctionnement fluide sans fonctionnalités inutiles.

Montage et entretien faciles