NXSD 310

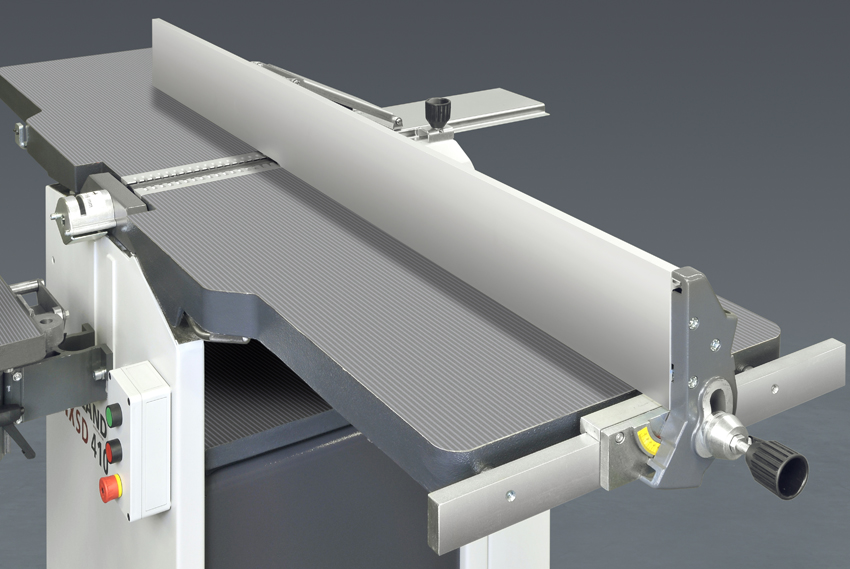

The NXSD 310 from our Essential Range combines top-tier performance with a space-saving design. Perfect for smaller workshops, this versatile machine seamlessly transitions between planing and thicknessing, allowing you to plane two surfaces and then shape your workpiece to the exact dimensions—all in one smooth process.

Precision and Efficiency

With high-quality cutters and precision-ground tables, the NXSD 310 delivers flawless finishes and consistent accuracy, minimizing the need for multiple passes. Its compact footprint ensures you get professional results without taking up valuable space.

Durable and Easy to Use

Built to last with industrial-grade materials, the NXSD 310 is designed for reliable performance with minimal maintenance. Ergonomic controls make it user-friendly, while integrated dust extraction keeps your workspace clean for better performance and air quality.

The NXSD 310 from our Essential Range combines top-tier performance with a space-saving design. Perfect for smaller workshops, this versatile machine seamlessly transitions between planing and thicknessing, allowing you to plane two surfaces and then shape your workpiece to the exact dimensions—all in one smooth process. Precision and Efficiency With high-quality cutters and precision-ground tables, the NXSD 310 delivers flawless finishes and consistent accuracy, minimizing the need for multiple passes. Its compact footprint ensures you get professional results without taking up valuable space. Durable and Easy to Use Built to last with industrial-grade materials, the NXSD 310 is designed for reliable performance with minimal maintenance. Ergonomic controls make it user-friendly, while integrated dust extraction keeps your workspace clean for better performance and air quality.

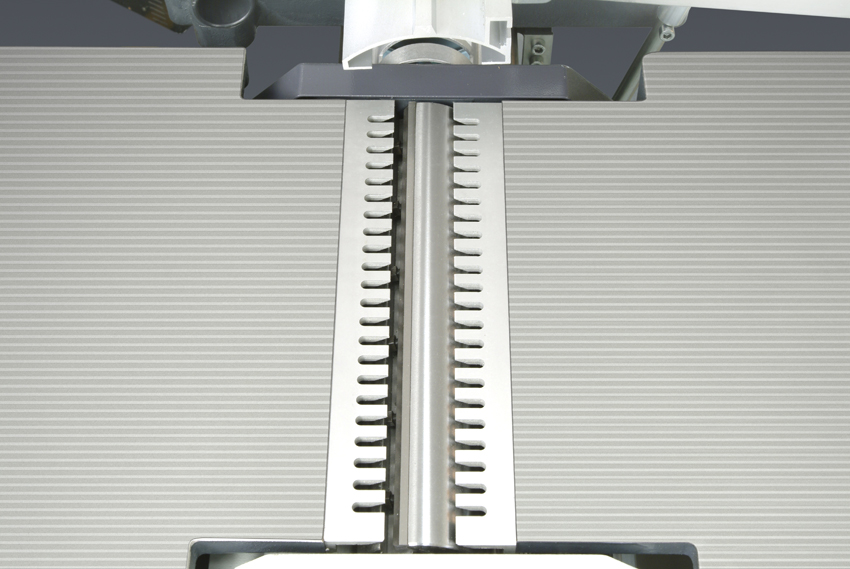

Hardwood silent power: Spiral cutter block

The planer thicknesser can also be equipped with an optional spiral cutter block, designed for a smoother and quieter woodworking experience. This innovative cutter block features a series of small, rectangular knives arranged in a spiral pattern, ensuring that each knife works incrementally for a fluent and efficient cutting process. The result is a significant reduction in noise and a finer finish on hardwoods.

However, the spiral cutter block is not recommended for softwoods like pine, due to two key factors:

Resin Content: Softwoods tend to have higher resin levels, which can clog and affect the cutter block’s performance.

Fibrous Texture: The fibrous nature of softwoods like pine can lead to tearing or fuzzing, reducing the overall finish quality.

For those primarily working with hardwoods, the spiral cutter block is an excellent upgrade, offering enhanced performance and a superior finish.

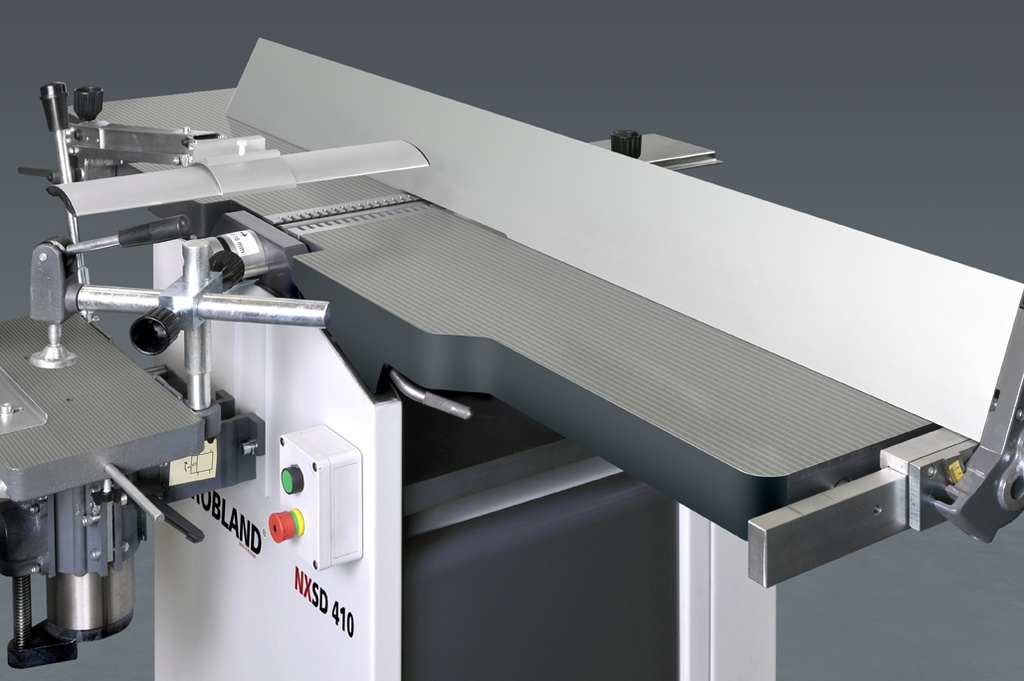

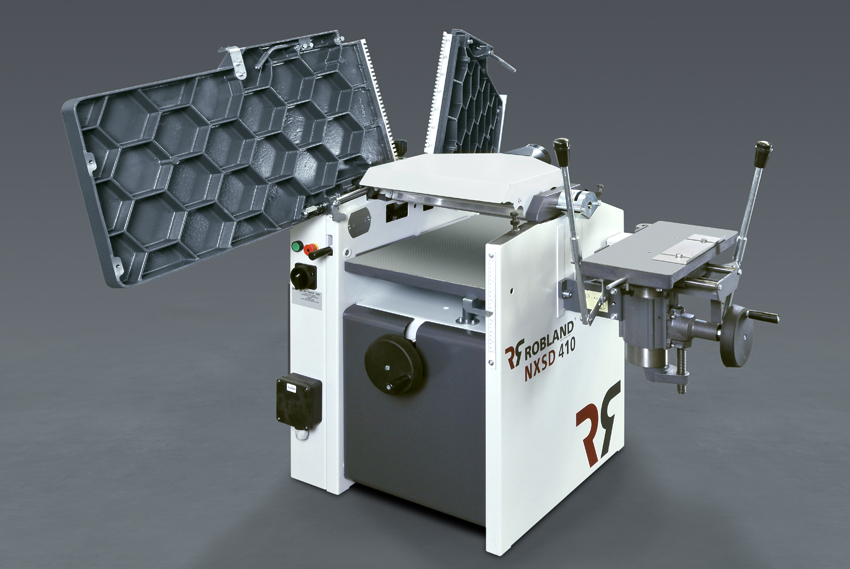

Strong Cast Iron Tables

Superior Strength with Honeycomb Structure

Our Cast Iron Tables are engineered for exceptional durability and performance. Featuring a robust honeycomb structure, these tables provide the best strength-to-weight ratio, ensuring reliable support without unnecessary bulk.

Triple-Planed for Optimal Quality

Each table undergoes a meticulous three-step planing process to ensure the highest standards of Robland Quality. Crafted from premium Belgian cast iron, the planing process is conducted in-house to maintain strict quality control:

- Initial Planing: The table is planed to achieve perfect flatness, creating a stable and even surface.

- Friction Reduction: The second step involves further planing to reduce friction, ensuring smooth operation during use.

- Signature Microgrooves: The final step introduces our signature microgrooves. This delicate removal of material results in minimal energy dissipation, enhancing the precision and ease of movement for wooden workpieces.

Enhanced Precision with Microgroove Technology

Our microgroove technology is the hallmark of our cast iron tables. These finely crafted grooves allow for effortless gliding of wood, minimizing resistance and ensuring maximum precision during cutting operations. The result is a table surface that not only supports high accuracy but also significantly reduces the effort required in handling materials.

The 3rd Operation: Mortising with the Mortising Table

The machine's 3rd operation: Mortising can be achieved by attaching our optional mortising unit, which utilizes the same axis as the planer-thicknesser. This versatile attachment allows you to drill precise holes or slots in your wood, expanding the machine’s functionality and making it an even more powerful tool for complex woodworking tasks.

SPECIFICATIONS

General

Planer-Thicknesser

Mortiser (Optional)

SPEED

Fast Belgian production with trusted European suppliers.

Focus on time and quality instead of costs.

Short supply chain reduces wait times and boosts efficiency.

SUSTAINABILITY

Lifetime spare parts

Responsible production for minimal environmental impact.

Focus on robust, reliable components

SIMPLICITY

User-friendly designs promoting efficiency.

Simple controls with a clear interface ensure smooth operation without unnecessary features.

Easy assembly and maintenance