T120 X2

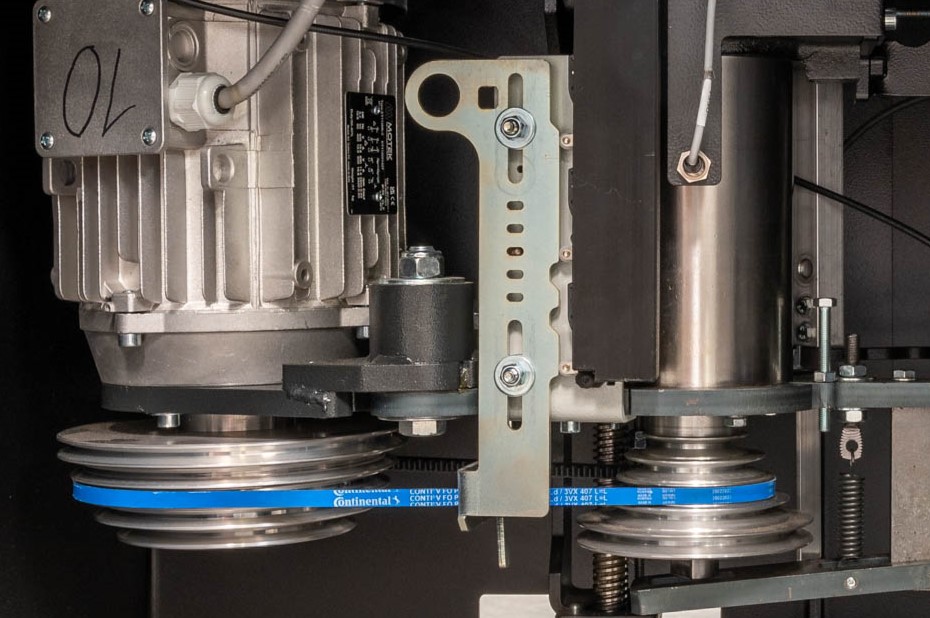

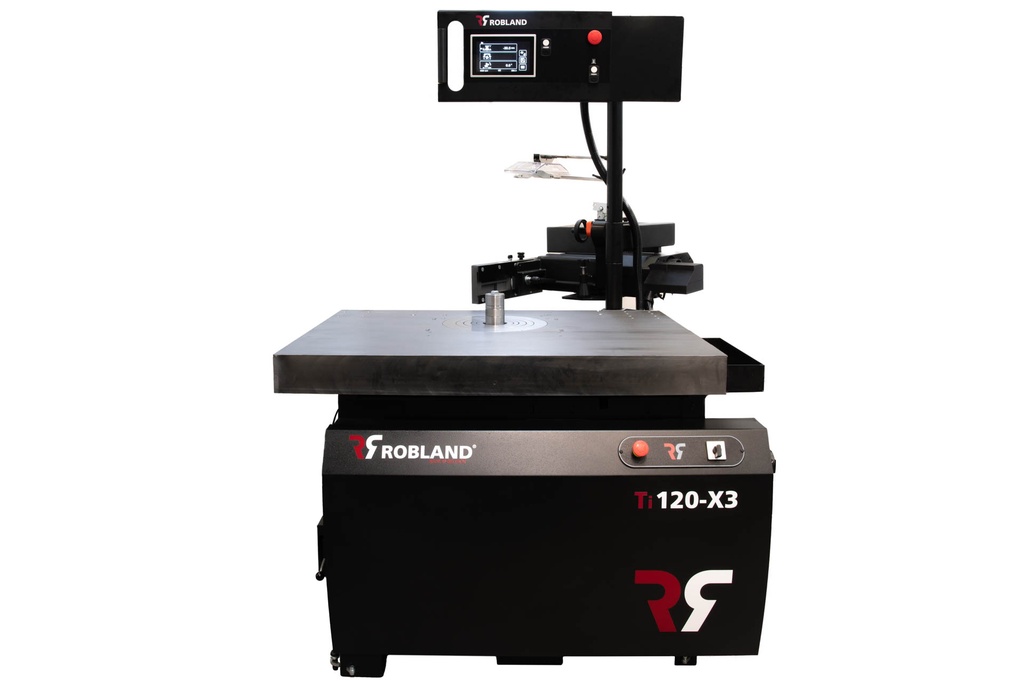

The T120 X2 is a major leap forward from the T120, designed to revolutionize your woodworking production with its fully numerical control system. Featuring our signature Robland Stepper motor technology, the T120 X2 offers unmatched reliability and ease of use.

Key Upgrades :

Numerical Control for Axis and Fence: The manual adjustments of the past are now fully automated. With precision control over both the spindle axis and fence, you can expect faster, more accurate setups every time.

Intuitive Touchscreen Interface: Even operators with little to no experience with numerical control will find the touchscreen easy to navigate. Designed for user-friendliness, it enables quick, accurate inputs for seamless operation.

Boost Your Productivity :

One-Time Tool Setup: Say goodbye to endless measurements. With the T120 X2, you only need to input your tool settings once. After that, they're just one click away—ready to be recalled and instantly applied whenever you need them.

Faster Production: By eliminating manual adjustments and streamlining tool changes, the T120 X2 enables your production to skyrocket, reducing downtime and boosting efficiency on every project.

The T120 X2 is a major leap forward from the T120, designed to revolutionize your woodworking production with its fully numerical control system. Featuring our signature Robland Stepper motor technology, the T120 X2 offers unmatched reliability and ease of use. Key Upgrades : Numerical Control for Axis and Fence: The manual adjustments of the past are now fully automated. With precision control over both the spindle axis and fence, you can expect faster, more accurate setups every time. Intuitive Touchscreen Interface: Even operators with little to no experience with numerical control will find the touchscreen easy to navigate. Designed for user-friendliness, it enables quick, accurate inputs for seamless operation. Boost Your Productivity : One-Time Tool Setup: Say goodbye to endless measurements. With the T120 X2, you only need to input your tool settings once. After that, they're just one click away—ready to be recalled and instantly applied whenever you need them. Faster Production: By eliminating manual adjustments and streamlining tool changes, the T120 X2 enables your production to skyrocket, reducing downtime and boosting efficiency on every project.

HIGHLIGHTED FEATURES

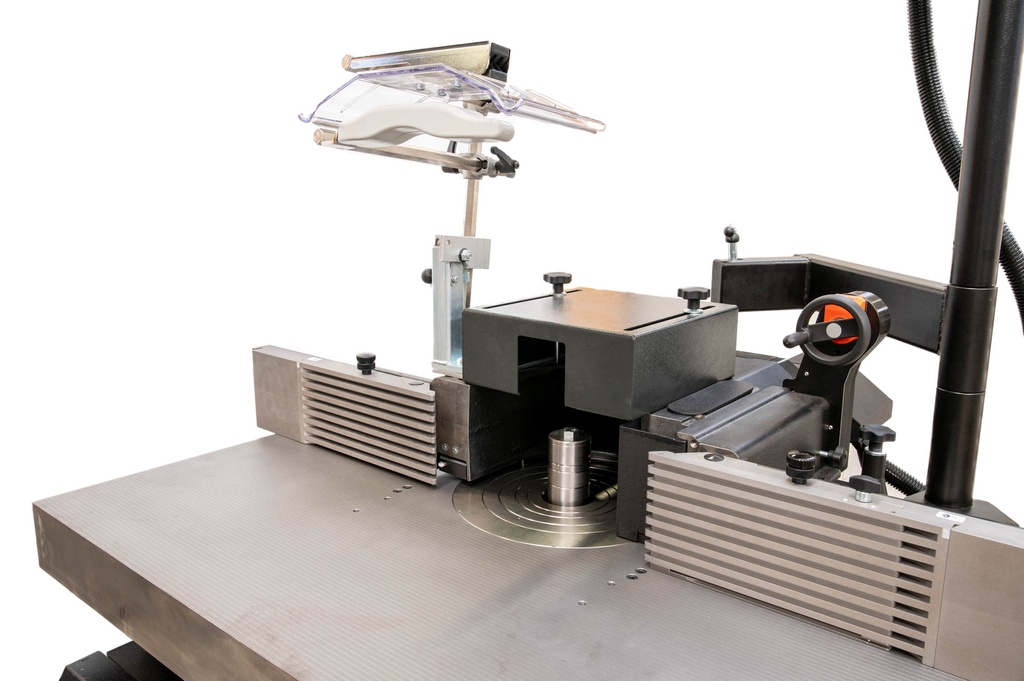

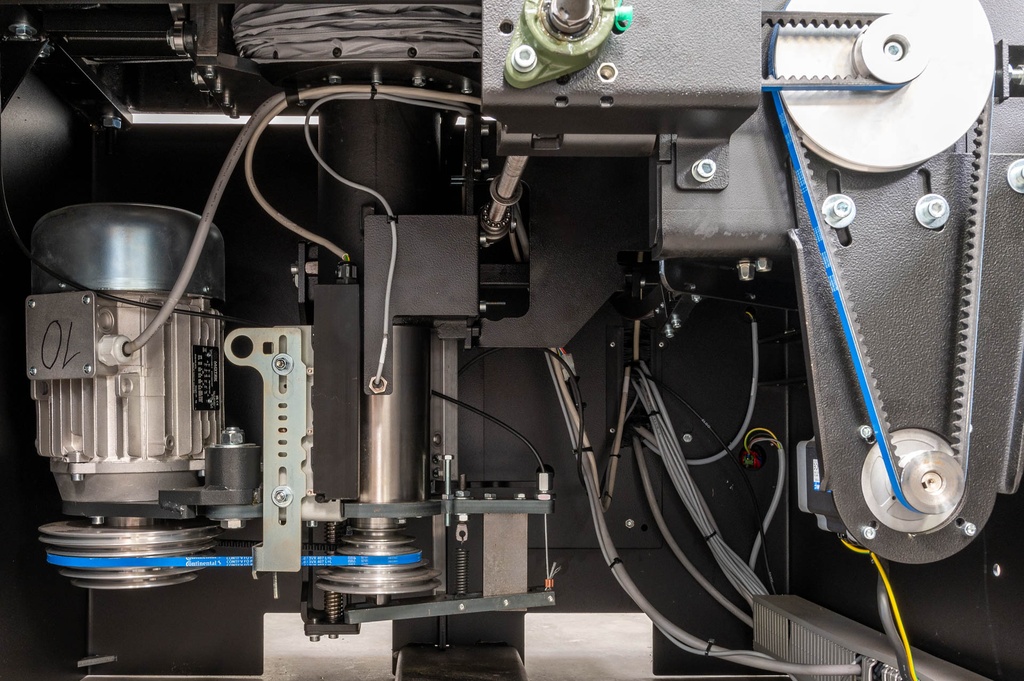

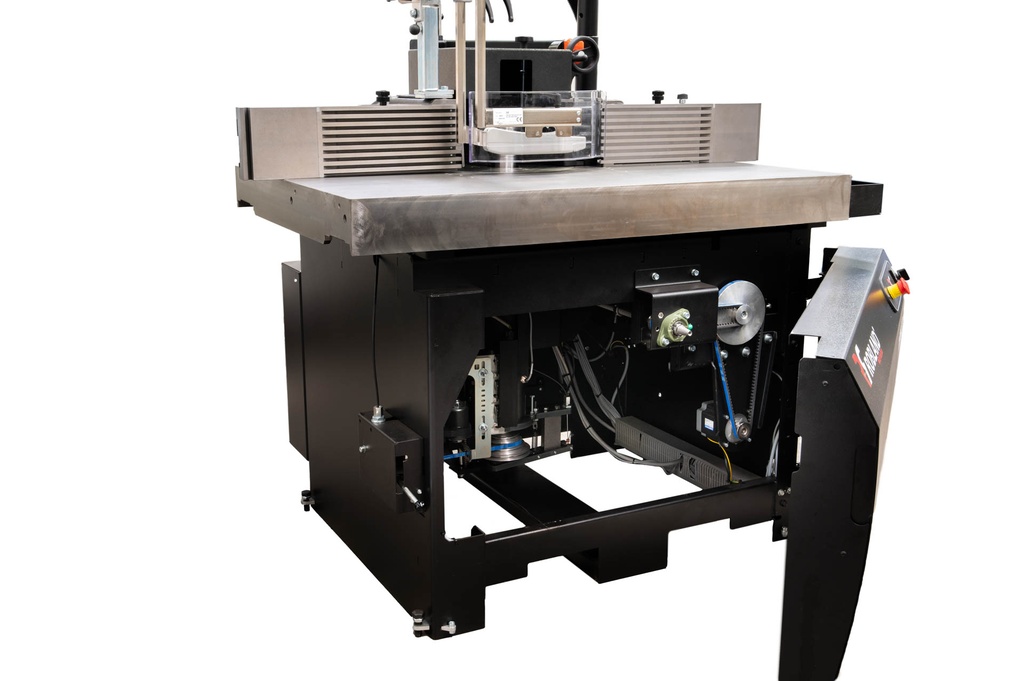

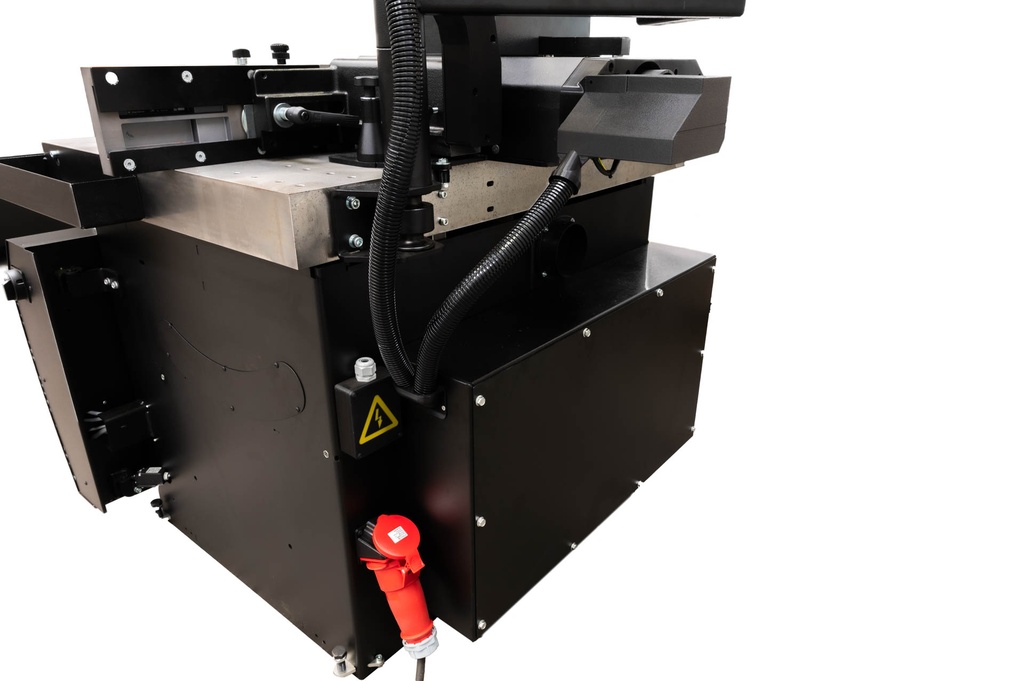

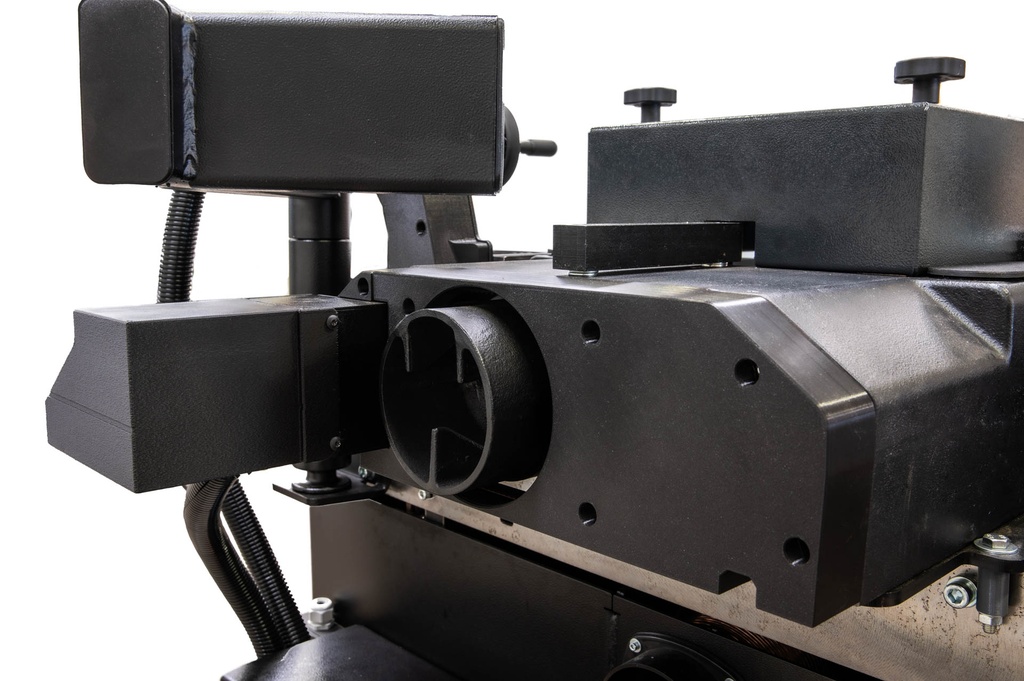

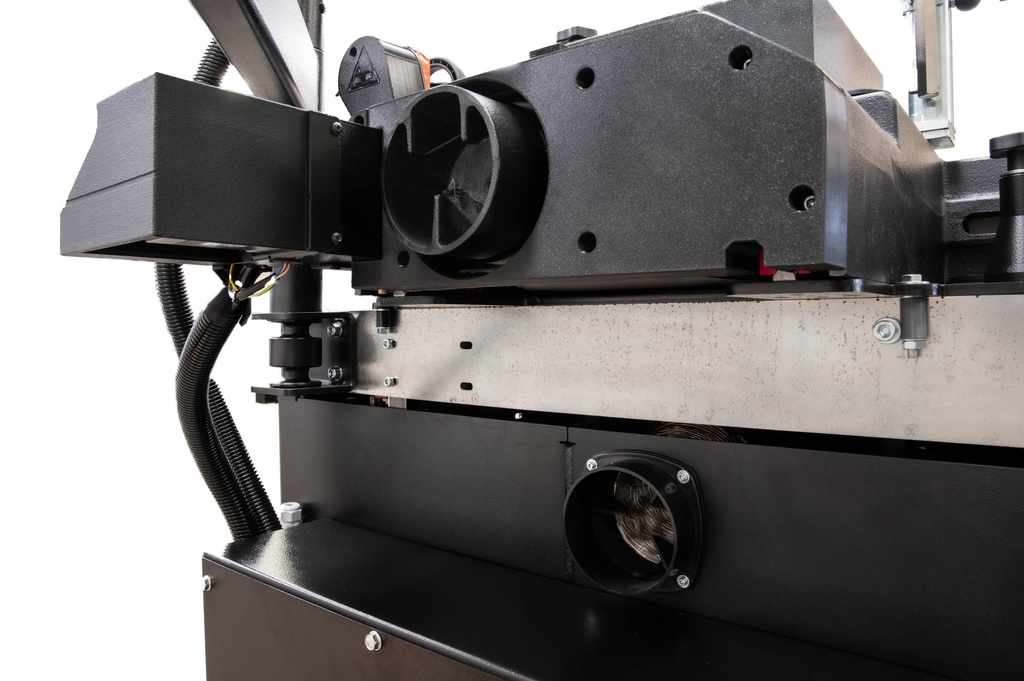

Welded Steel Frame for Stability and Easy Maintenance

The T120 X2 is equipped with a newly designed welded steel frame, providing unmatched stability and durability for long-lasting performance.

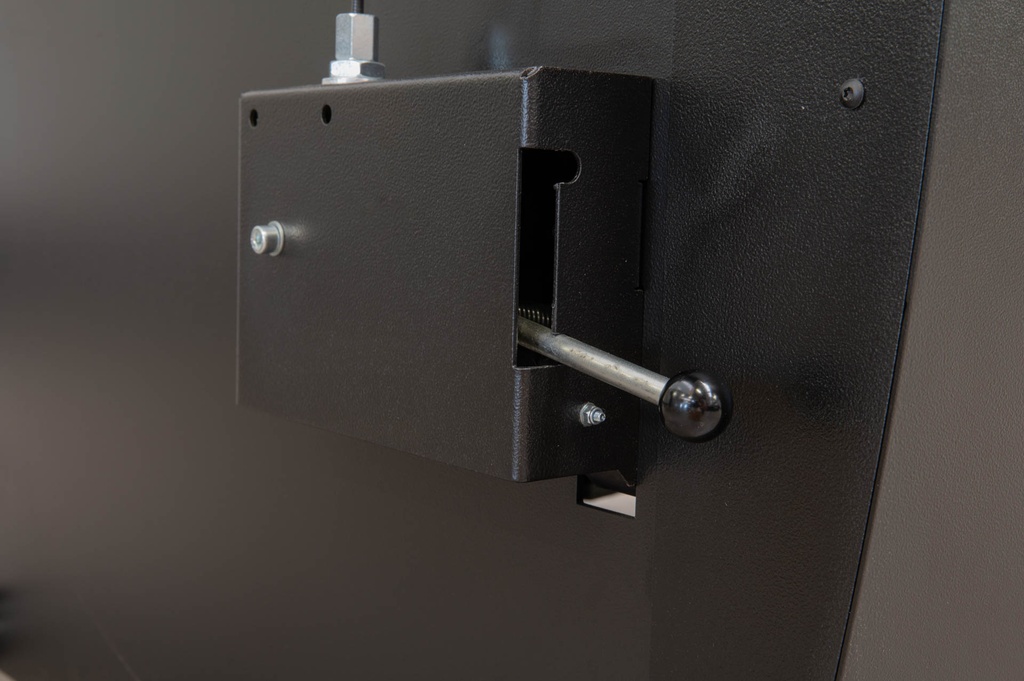

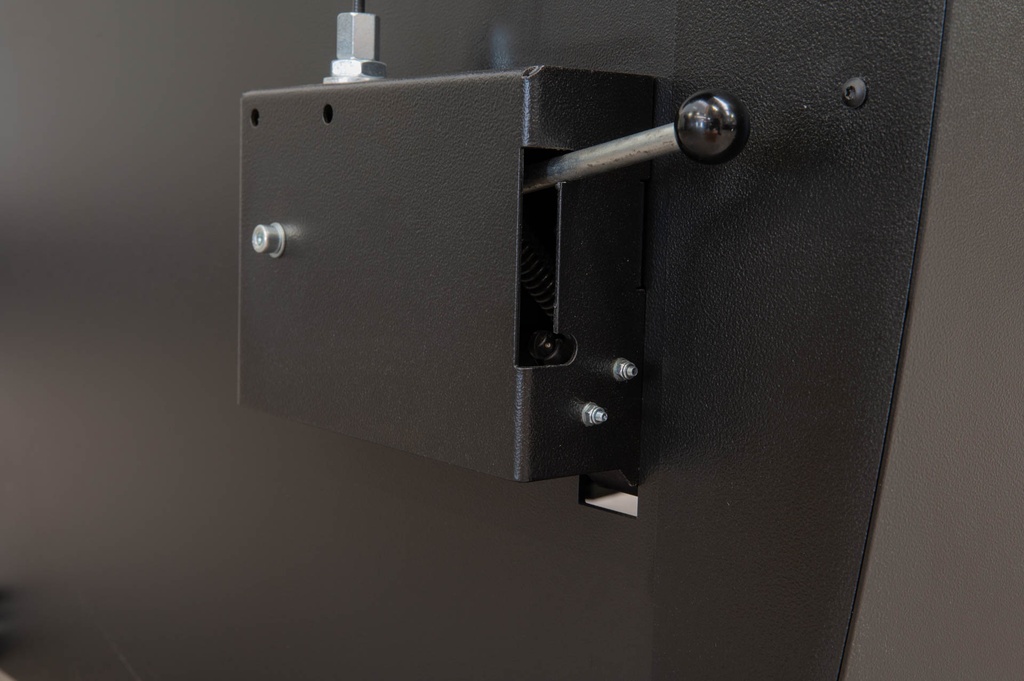

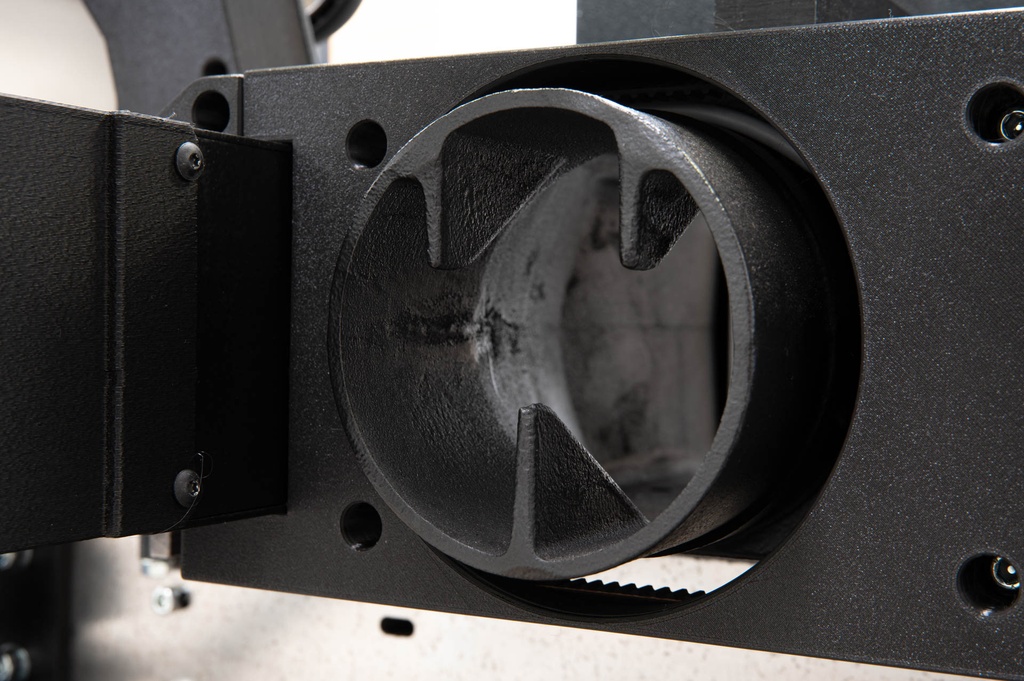

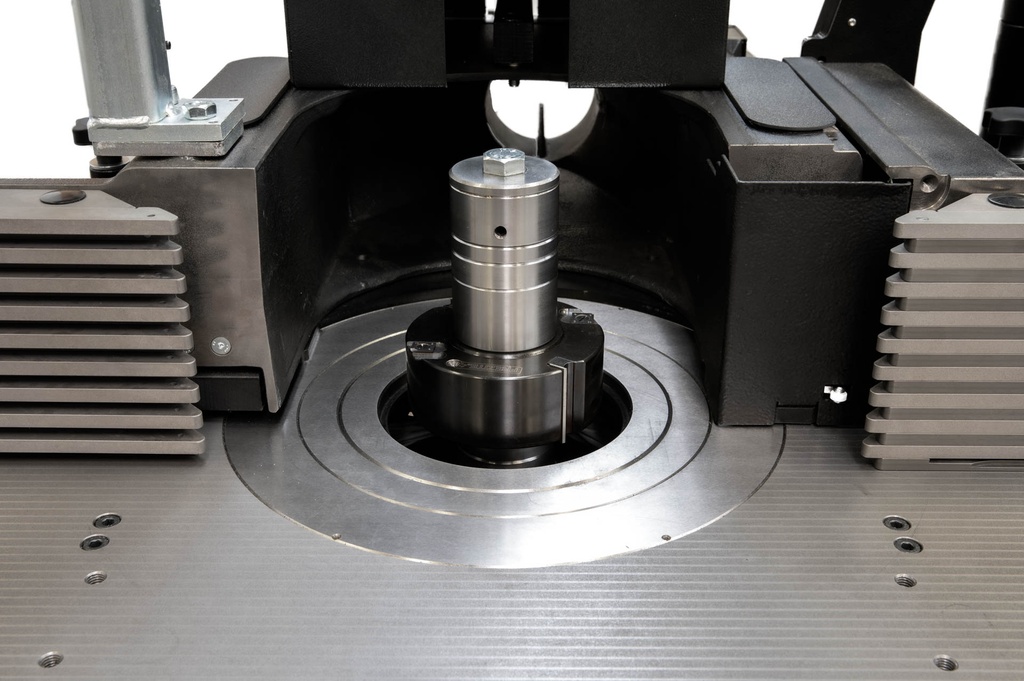

Easy Access for Quick Maintenance

A convenient front-access door allows for fast spindle speed changes and easy maintenance, ensuring smooth operation and reducing downtime in your workflow.

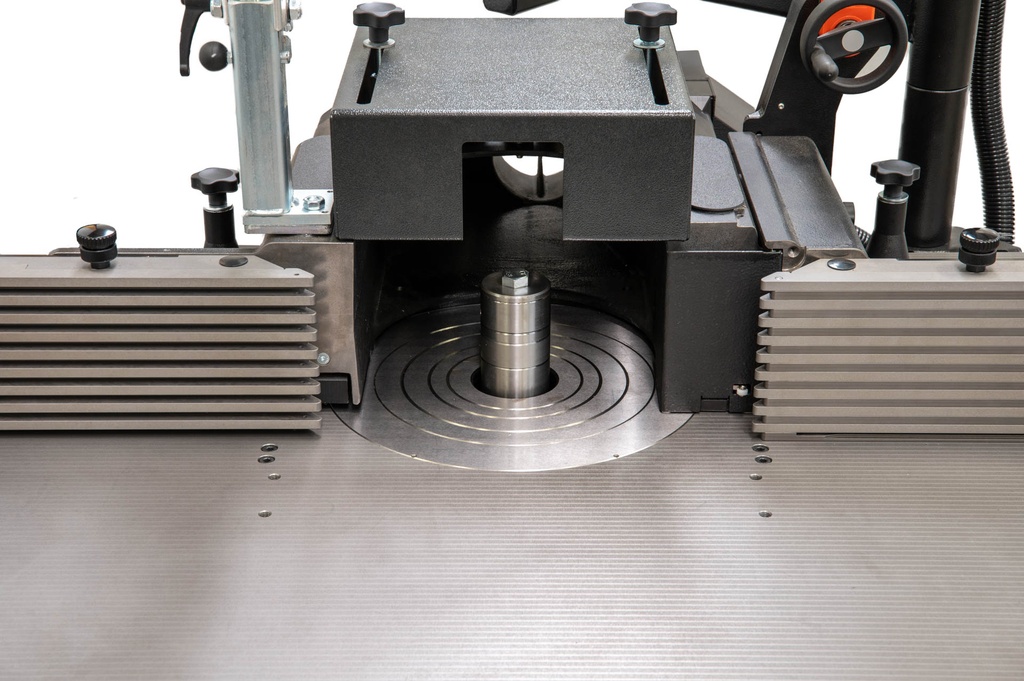

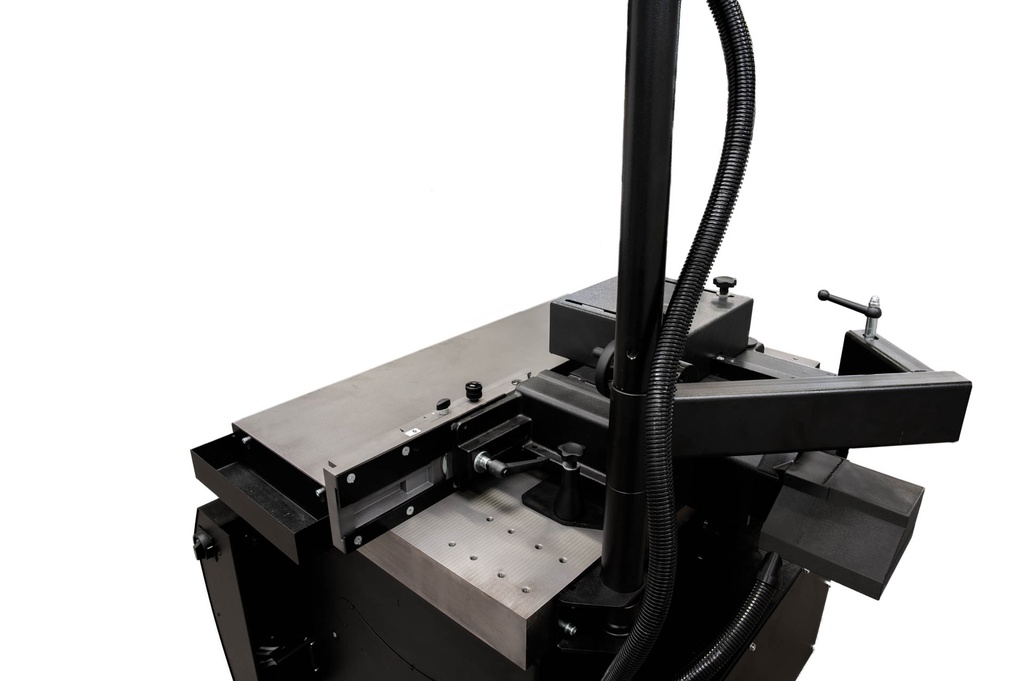

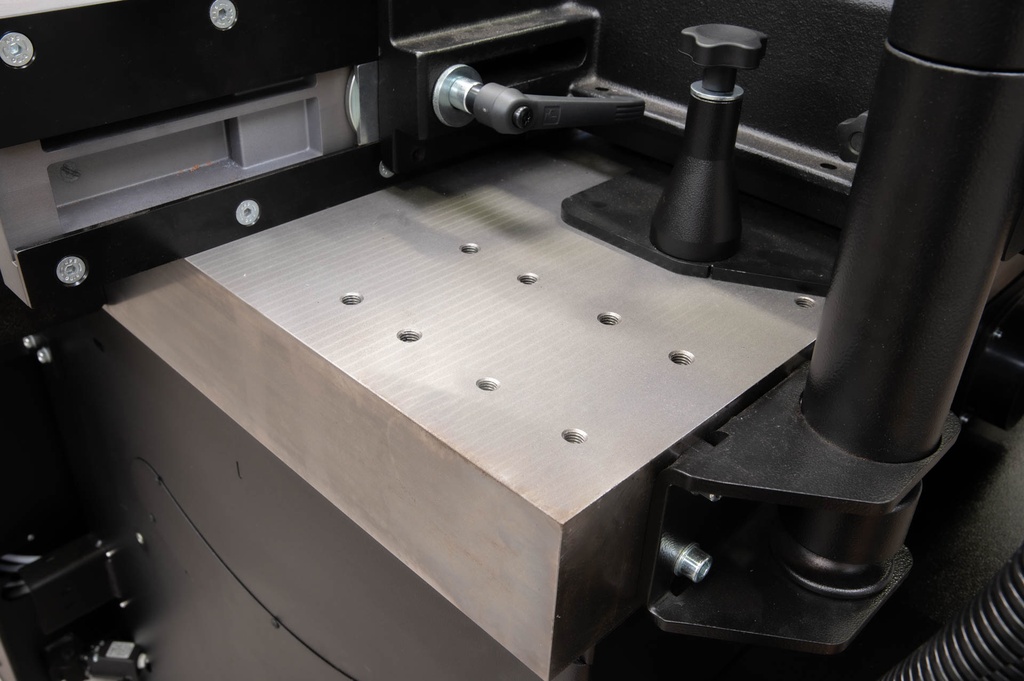

Robust Cast Iron Table for Maximum Support

The sturdy steel frame supports a large cast iron table, offering maximum support and stability during milling tasks. This makes the T120 X2 ideal for both precision and heavy-duty work, delivering high-quality results in every project.

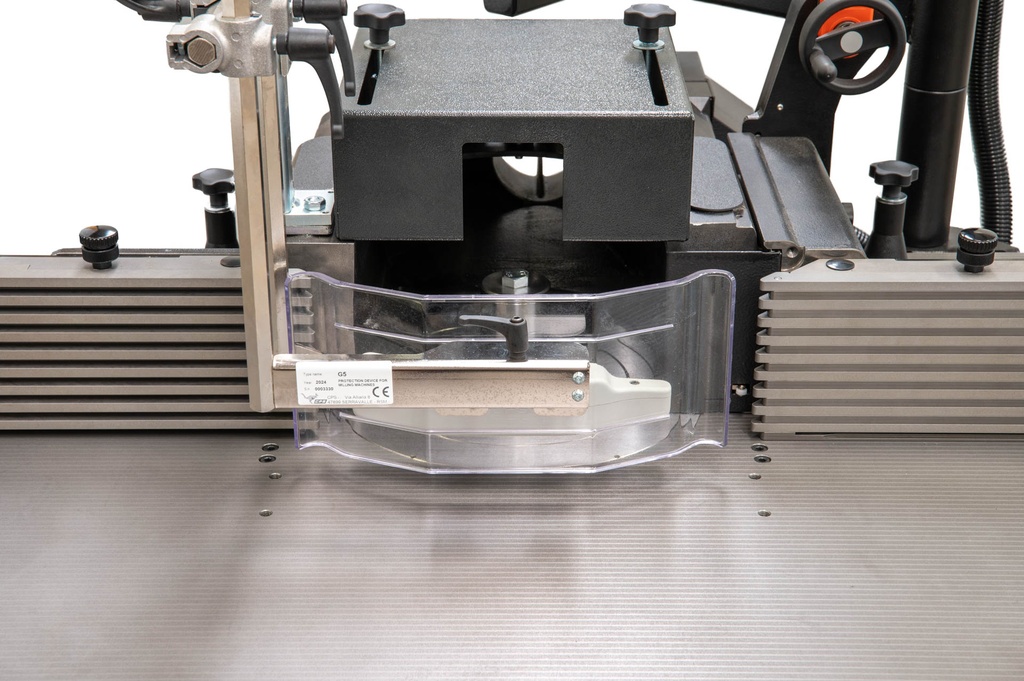

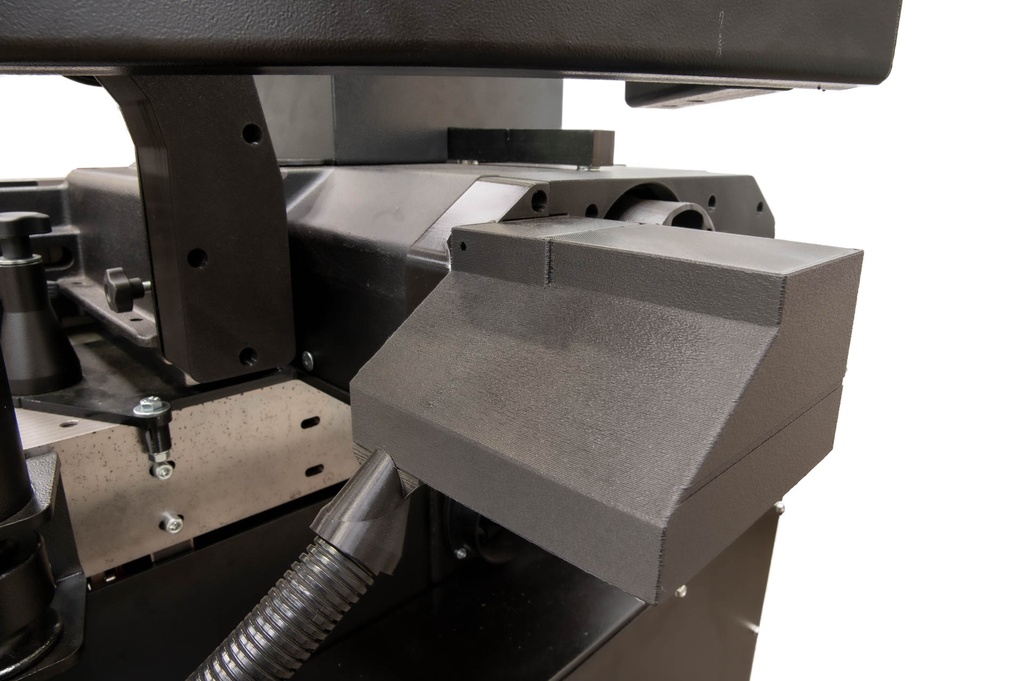

Touchscreen Control – Intuitive and Powerful

The T120 X2 stands out with its advanced touchscreen control, making axis and fence adjustments quick and intuitive.

Boost Productivity and Ease of Use

The touchscreen dramatically increases both productivity and ease of use, streamlining the entire operation. With an interface designed for user-friendliness, even operators with minimal experience can navigate the system effortlessly.

Simplified Control with Just a Few Taps

Robland’s touchscreen allows for precision control with minimal effort. Simply tap to make adjustments, eliminating the need for manual fine-tuning and reducing setup time.

Speed Up Production

By automating key adjustments, the touchscreen helps you speed up production like never before, making your workflow smoother and more efficient.

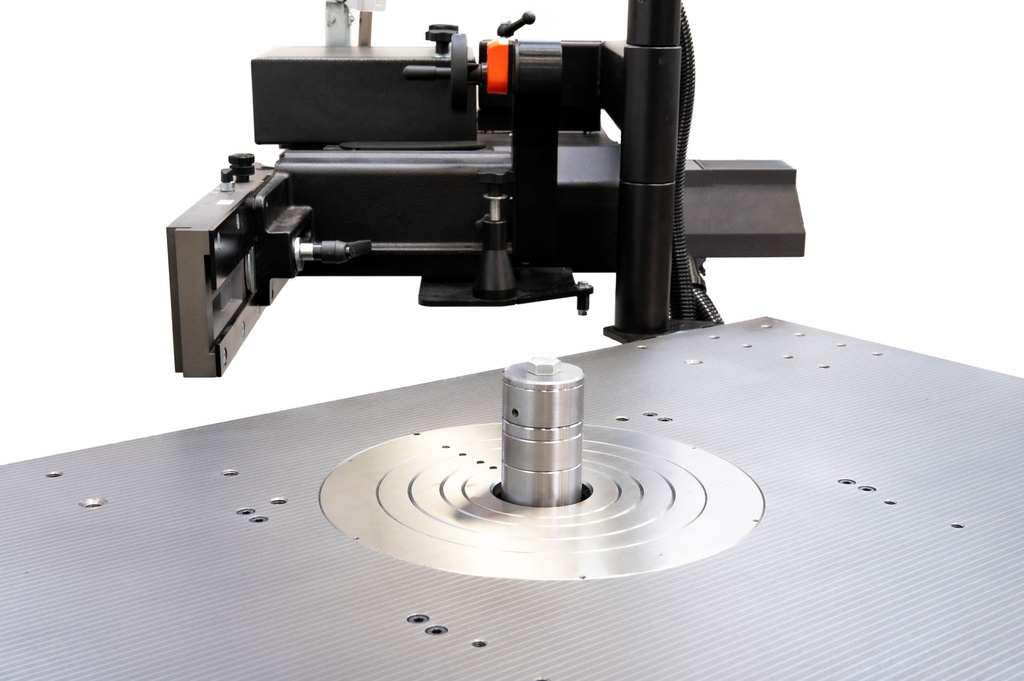

Table Extensions for Handling Larger Workpieces

For workshops that need to tackle larger woodworking projects, the T120 X2 spindle moulder can be equipped with heavy-duty cast iron table extensions. These robust extensions are designed to significantly increase the machine’s work surface, providing the space and support necessary to handle oversized pieces with ease.

Enhanced Work Surface for Bigger Projects

The cast iron table extensions dramatically expand both the length and width of the spindle moulder, making it possible to work comfortably with larger workpieces. Whether you're handling long boards, wide panels, or bulky materials, the extended surface gives you the stability and space you need to complete even the most demanding tasks.

Increased Stability and Precision

With the additional support from the table extensions, you gain greater control and stability over your materials. This ensures precise cuts and consistent results, even when working with heavier or longer pieces. The added surface area reduces the need for additional support structures, keeping your workflow smooth and efficient.

Broader Range of Applications

By expanding the capabilities of your spindle moulder, the table extensions make the machine suitable for a broader range of tasks. From furniture production to architectural woodworking, these extensions allow you to handle large-scale projects that would otherwise be difficult to manage on a standard work surface.

SPECIFICATIONS

General specifications

Spindle

SPEED

Fast Belgian production with trusted European suppliers.

Focus on time and quality instead of costs.

Short supply chain reduces wait times and boosts efficiency.

SUSTAINABILITY

Lifetime spare parts

Responsible production for minimal environmental impact.

Focus on robust, reliable components

SIMPLICITY

User-friendly designs promoting efficiency.

Simple controls with a clear interface ensure smooth operation without unnecessary features.

Easy assembly and maintenance