M500 X1/X3

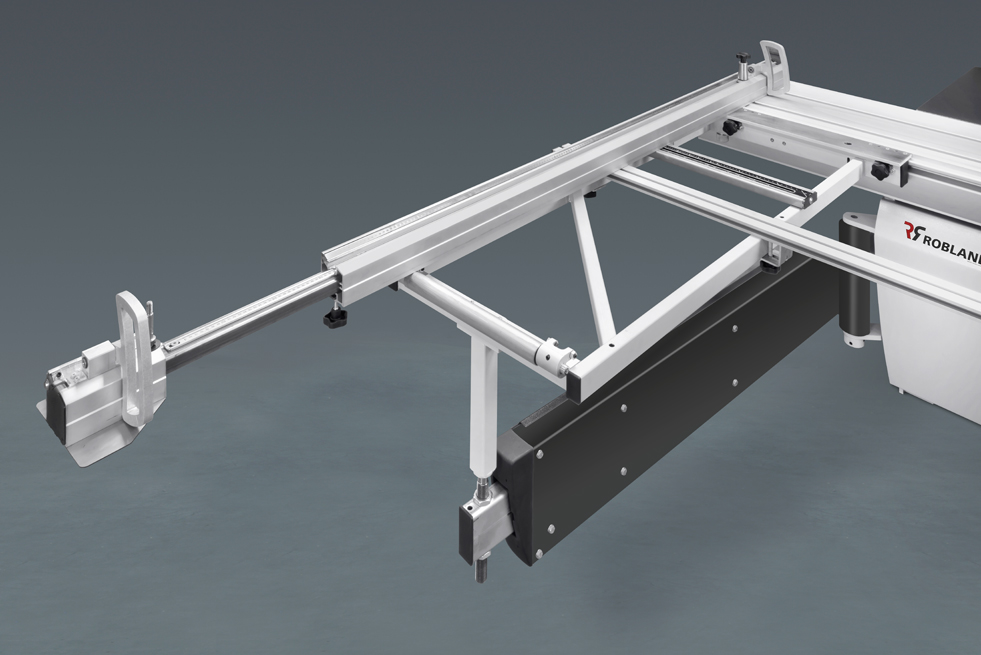

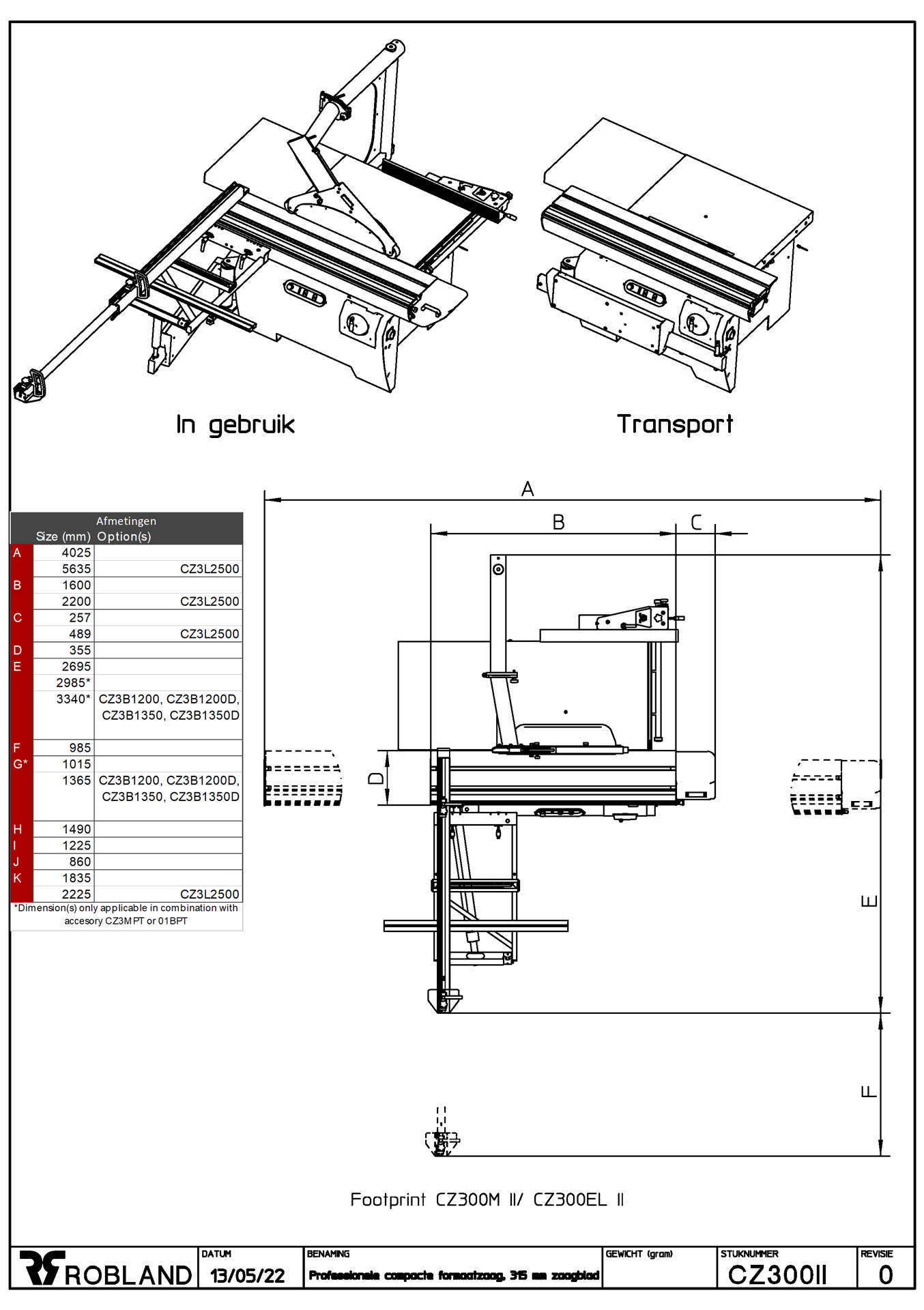

The M500 X1/X3 is the advanced numerical version of our modular M500 panel saw, offering enhanced precision and efficiency for demanding workshops. Built on the solid foundation of the Z500, this model supports a maximum saw blade diameter of 500mm and a cutting height of 175mm. The X1 version provides numerical control of the parallel guide, while the X3 version adds control over the height and tilt of the saw blade. Designed for customization, the M500 X1/X3 allows you to adjust key features like cutting length, cutting width, and outrigger tables to create the perfect setup for your needs. Combining flexibility with cutting-edge technology, this machine delivers unparalleled performance tailored to your specific requirements.

The M500 X1/X3 is the advanced numerical version of our modular M500 panel saw, offering enhanced precision and efficiency for demanding workshops. Built on the solid foundation of the Z500, this model supports a maximum saw blade diameter of 500mm and a cutting height of 175mm. The X1 version provides numerical control of the parallel guide, while the X3 version adds control over the height and tilt of the saw blade. Designed for customization, the M500 X1/X3 allows you to adjust key features like cutting length, cutting width, and outrigger tables to create the perfect setup for your needs. Combining flexibility with cutting-edge technology, this machine delivers unparalleled performance tailored to your specific requirements.

HIGHLIGHTED FEATURES

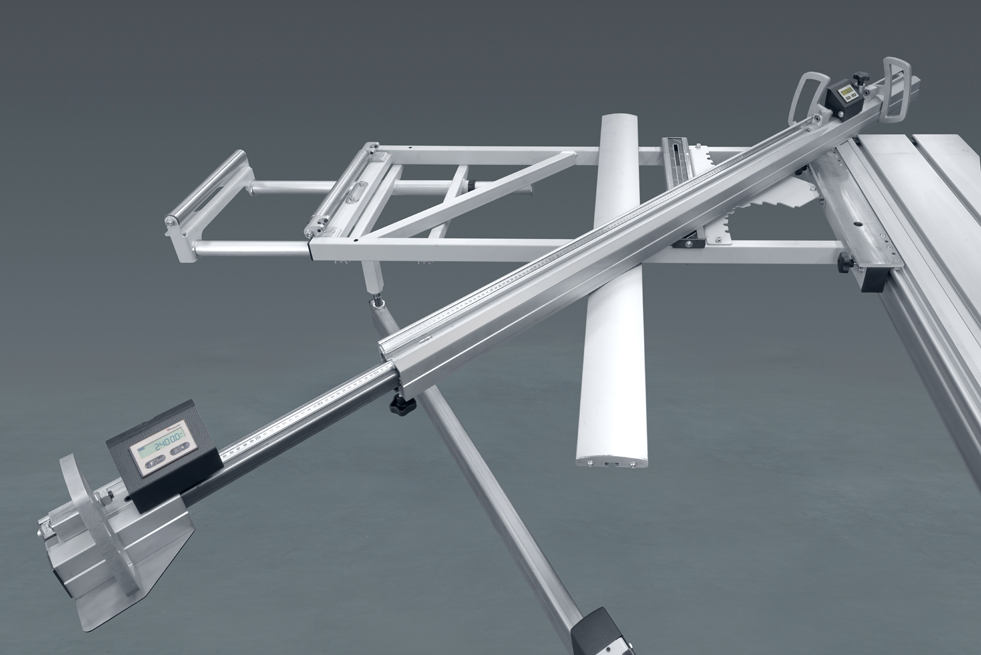

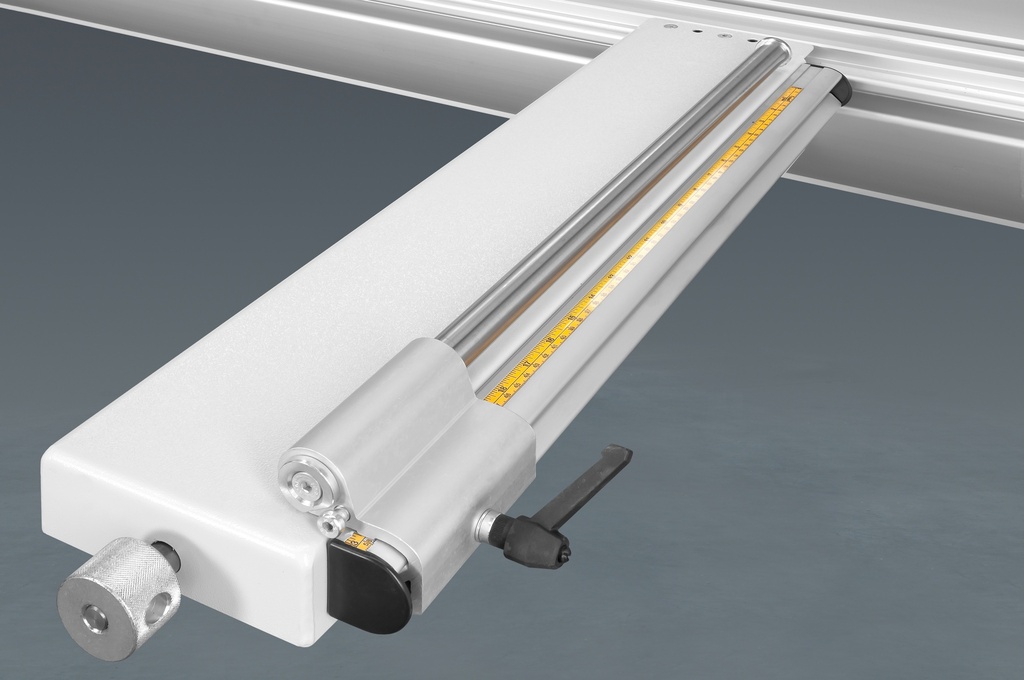

Numerical control

The M500 X1/X3 machine delivers unmatched accuracy and control with its advanced numerical control system. The rip fence, which is powered by stepper motors, moves on a spindle, ensuring the highest level of precision. This combination of spindle movement and stepper motor technology guarantees a reliable and exact method for adjusting the rip fence, making it ideal for professionals seeking perfect cuts every time.

Streamlined operation

Easily manage your workflow with dedicated buttons to start/stop the scoring unit and main saw blade. An emergency brake adds an extra layer of safety, giving you peace of mind during operation.

Convenient workflow

The built-in clipboard keeps your instructions and notes organized and within reach, enhancing your efficiency and ensuring a smooth workflow.

Perfect for professionals

Tailored for woodworkers who demand top-tier precision and control, the Z500 X1/X3 is the perfect tool for those looking to elevate their craft to the highest level.

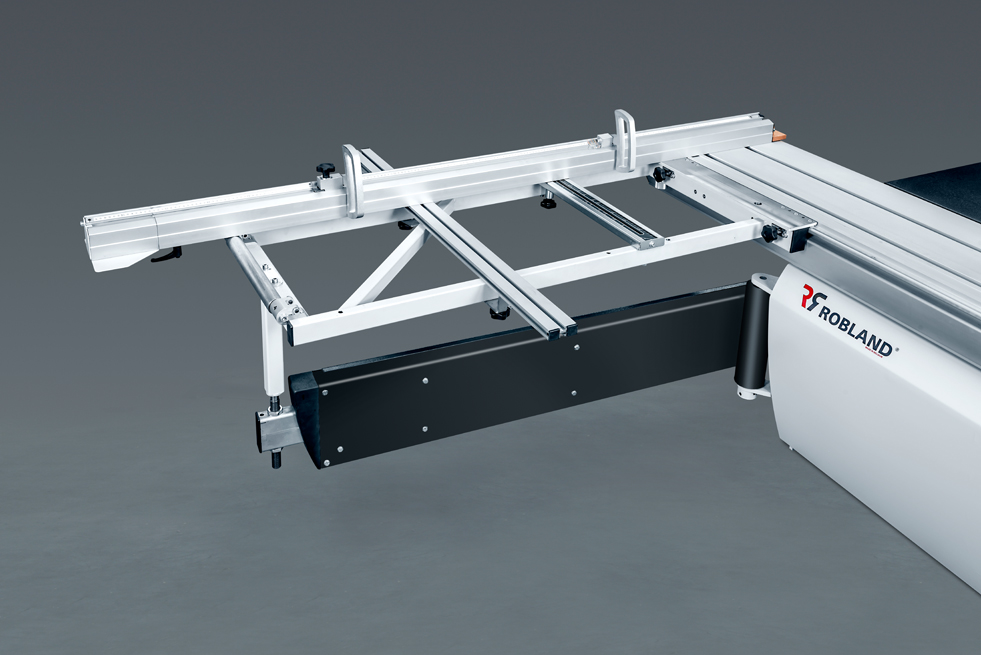

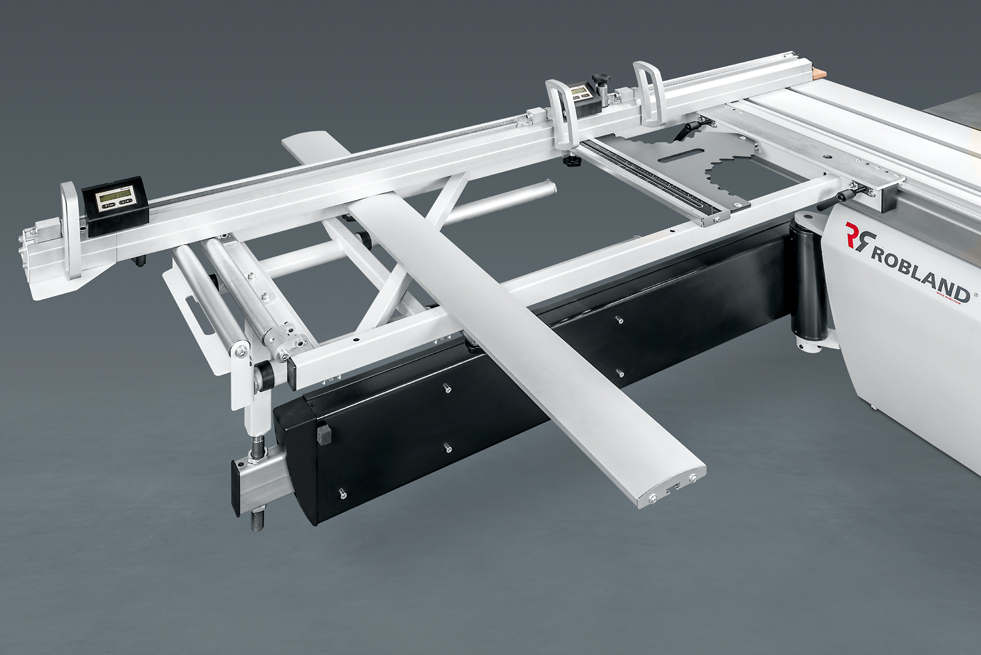

BOSS Sliding table

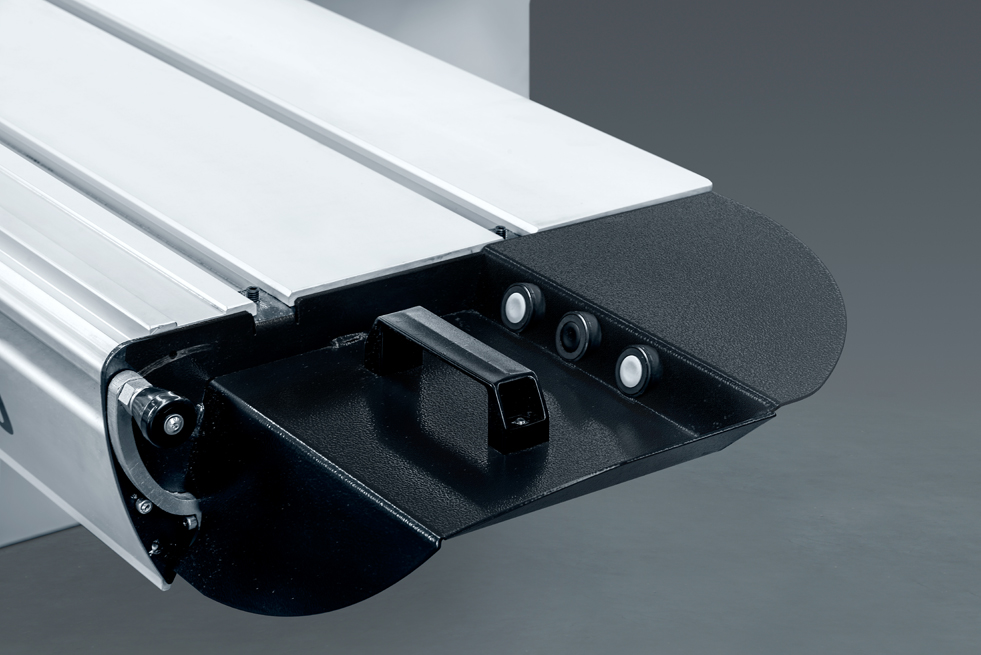

Revolutionary Design for Unmatched Precision

The BOSS Sliding Table System is built around our groundbreaking Balls On Solid Steel (BOSS) design, delivering the highest level of smoothness and accuracy. This advanced system ensures that every movement of the carriage is effortless and precise, making it an essential feature for achieving exceptional results in woodworking.

Frictionless Carriage Movement

Hardened steel balls glide seamlessly along solid steel shafts, creating a frictionless operation that guarantees precise and smooth movement. This innovative design minimizes resistance, allowing for easy and accurate adjustments, even under heavy loads.

Low-Maintenance Cleanliness

To ensure the system remains in optimal condition, replaceable cleaning sponges are installed at each end of the sliding table. These sponges effectively remove dust and debris from the shafts, maintaining the cleanliness of the system with minimal upkeep. This feature ensures that the BOSS Sliding Table System remains consistent and reliable, offering years of effortless operation.

Cast Iron Saw Aggregate

Engineered for Excellence

At the core of the M500 is our commitment to precision and quality, with nearly every component meticulously crafted in-house. The cast iron saw aggregate, a cornerstone of the machine’s performance, pivots on two precisely machined cast iron shells. This high level of precision is made possible by our dedication to producing these critical components ourselves, ensuring that every M500 meets the highest standards of quality and durability.

Comprehensive In-House Manufacturing

Beyond the saw aggregate, we take pride in manufacturing almost every part of the M500 in-house, from the saw-axis to the frame and beyond. This hands-on approach allows us to maintain complete control over the production process, guaranteeing the exceptional performance that our machines are known for. By making nearly everything in-house, we can ensure that each component is engineered to exacting standards, resulting in a machine that delivers reliable, professional-grade results.

SKF Collaboration for Enhanced Bearing Longevity

To minimize play in the saw axis and ensure precise operation, we apply a controlled force on our bearings. Recognizing the need for both precision and durability under these conditions, we partnered with SKF to develop a bearing system that extends lifespan while maintaining accuracy. This collaboration has led to a solution that enhances the performance and longevity of our machines, even under demanding conditions.

Strengths

SPECIFICATIONS

General specifications

Main saw blade

Scoring unit

Rip fence

Cutting length

SPEED

Fast Belgian production with trusted European suppliers.

Focus on time and quality instead of costs.

Short supply chain reduces wait times and boosts efficiency.

SUSTAINABILITY

Lifetime spare parts

Responsible production for minimal environmental impact.

Focus on robust, reliable components

SIMPLICITY

User-friendly designs promoting efficiency.

Simple controls with a clear interface ensure smooth operation without unnecessary features.

Easy assembly and maintenance