Xi410

Robland Xi410 – APEX Series: The Ultimate in Combined Machines.

The Xi410 is part of Robland’s exclusive APEX series, known for its sleek black design and cutting-edge performance. Built with the same frame and saw aggregate as our full-size panel saws, this high-end combined machine is the pinnacle of professional woodworking equipment.

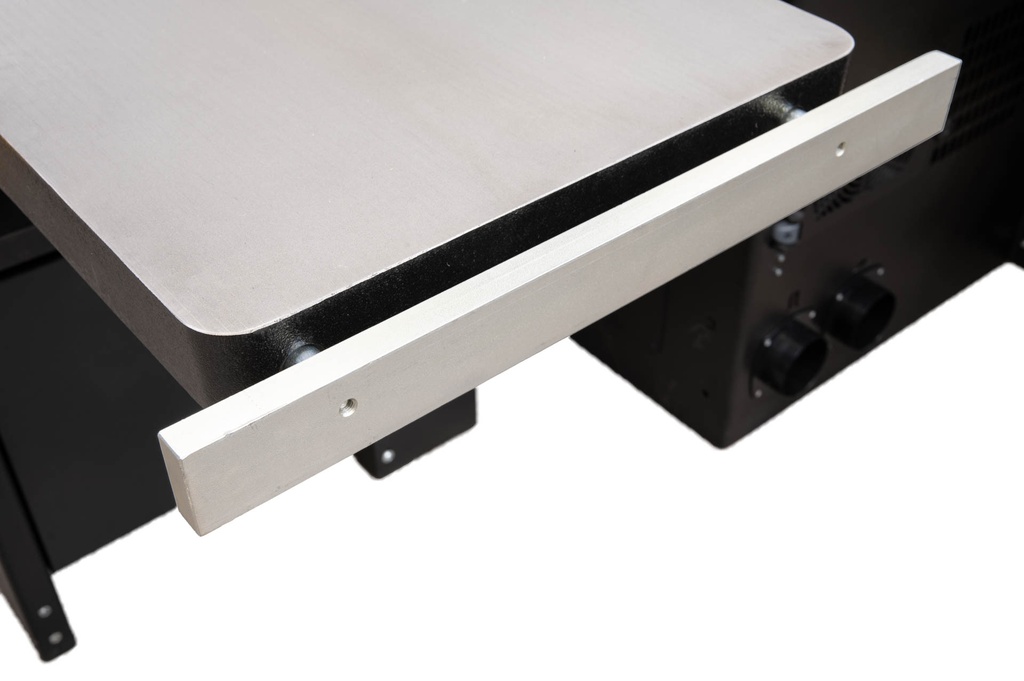

The difference with the Xi310 are the wider and longer cast iron planing tables. This results in 100 mm extra cutting width as well as planning width. The length of the tables is also 400 mm longer in total.

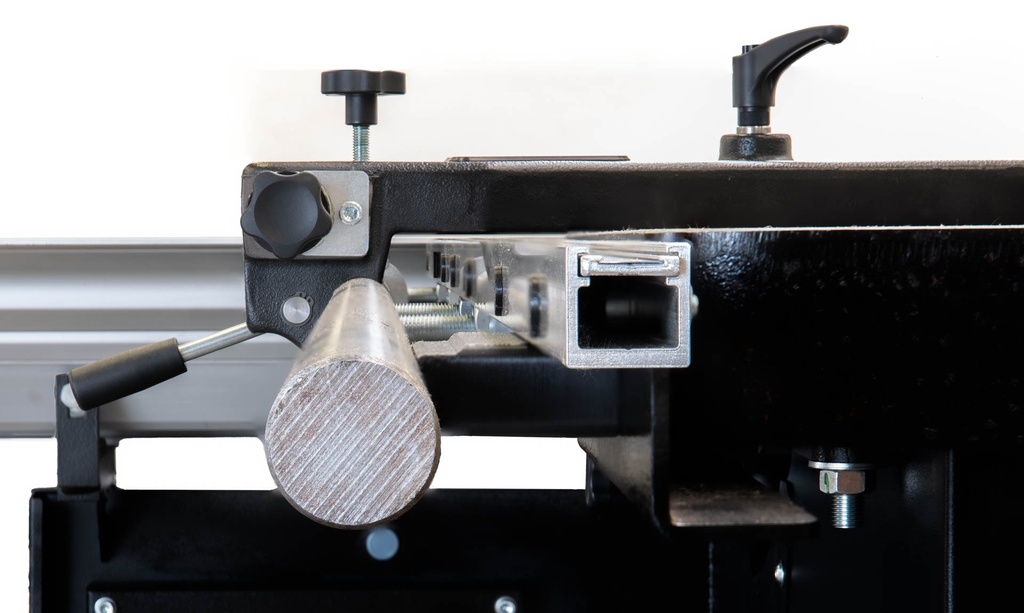

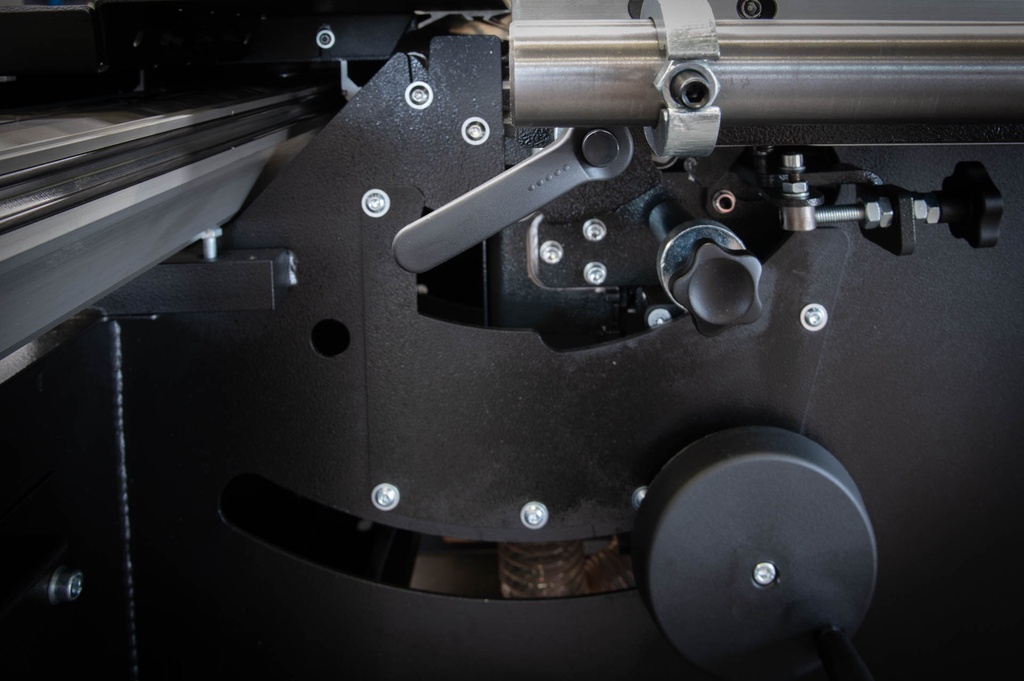

Key upgrades include the saw axis, which has been increased from 17 mm to an impressive 30 mm diameter, matching the power and precision of our full-scale panel saws. Additionally, the i-series introduces a tiltable spindle, further enhancing the machine’s versatility for complex tasks.

With five other operations seamlessly integrated, the Xi410 offers the functionality of a professional panel saw combined with unmatched flexibility, making it a true powerhouse for any woodworking professional.

Robland Xi410 – APEX Series: The Ultimate in Combined Machines. The Xi410 is part of Robland’s exclusive APEX series, known for its sleek black design and cutting-edge performance. Built with the same frame and saw aggregate as our full-size panel saws, this high-end combined machine is the pinnacle of professional woodworking equipment. The difference with the Xi310 are the wider and longer cast iron planing tables. This results in 100 mm extra cutting width as well as planning width. The length of the tables is also 400 mm longer in total. Key upgrades include the saw axis, which has been increased from 17 mm to an impressive 30 mm diameter, matching the power and precision of our full-scale panel saws. Additionally, the i-series introduces a tiltable spindle, further enhancing the machine’s versatility for complex tasks. With five other operations seamlessly integrated, the Xi410 offers the functionality of a professional panel saw combined with unmatched flexibility, making it a true powerhouse for any woodworking professional.

HIGHLIGHTED FEATURES

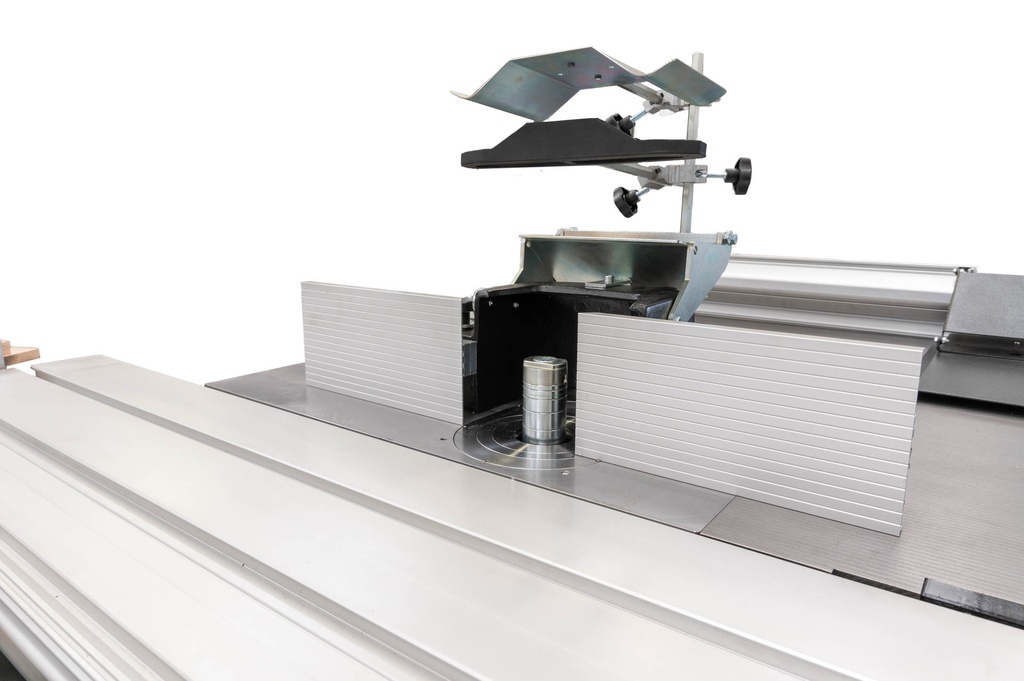

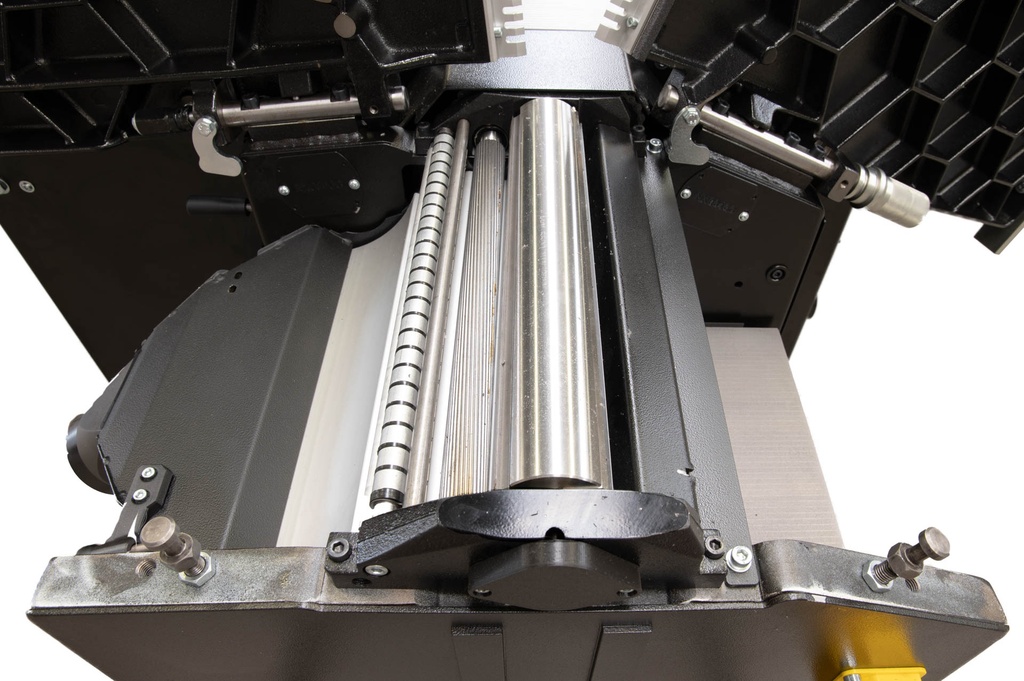

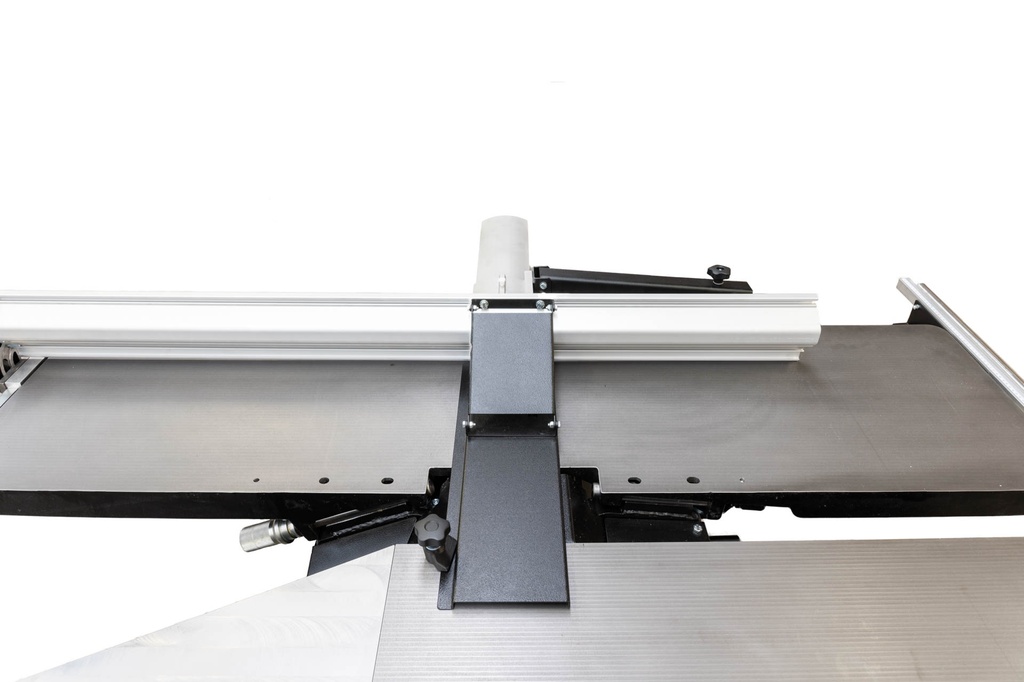

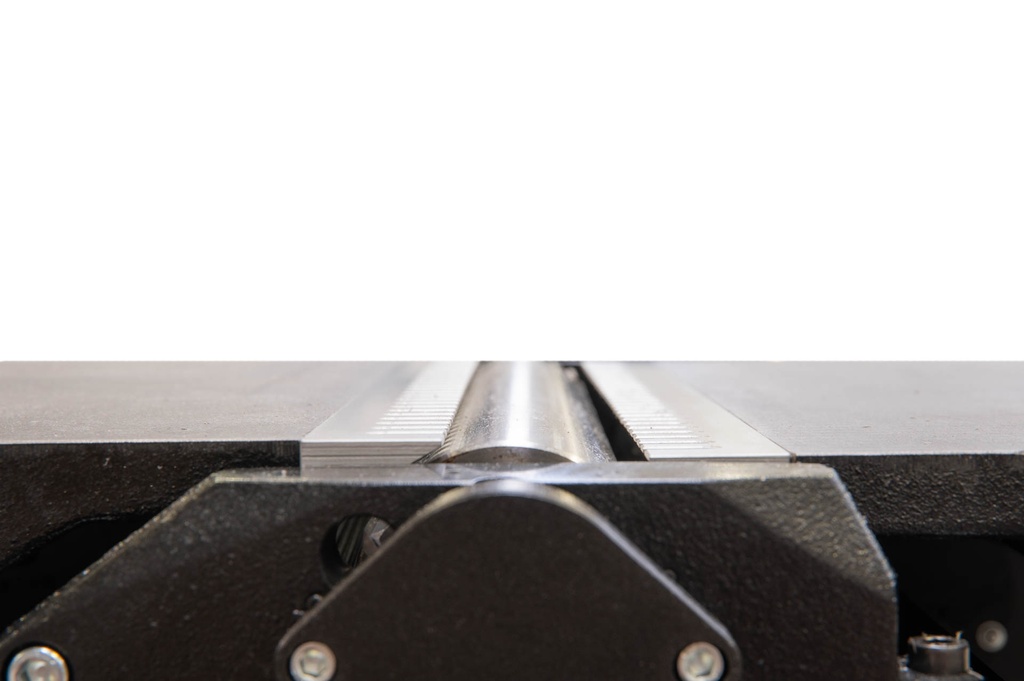

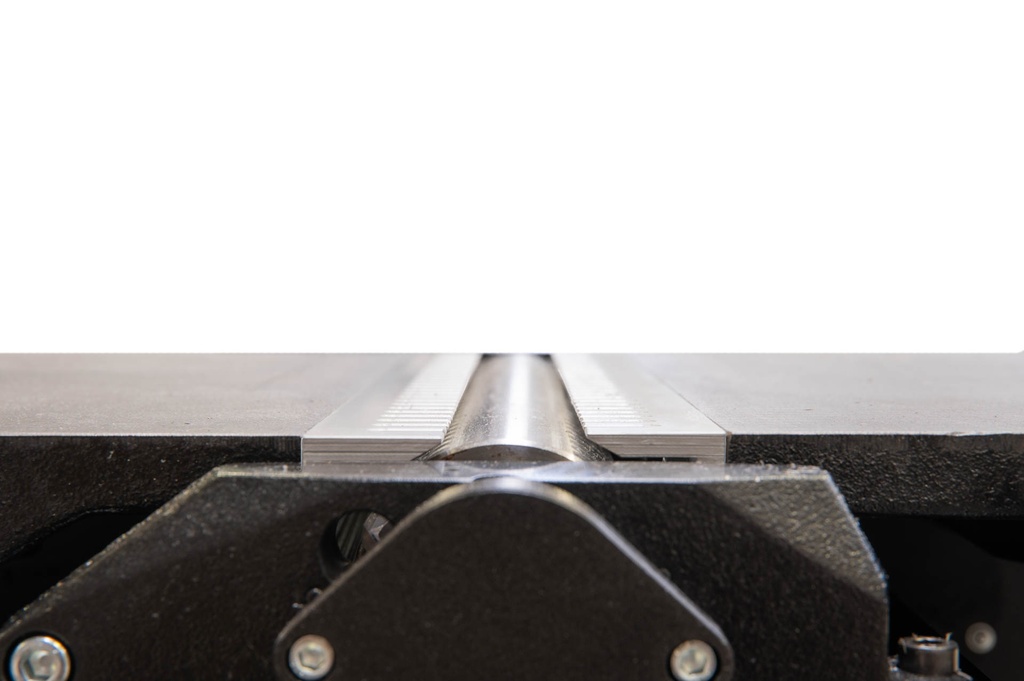

Xi 410 Precision Sawing with Enhanced Stability

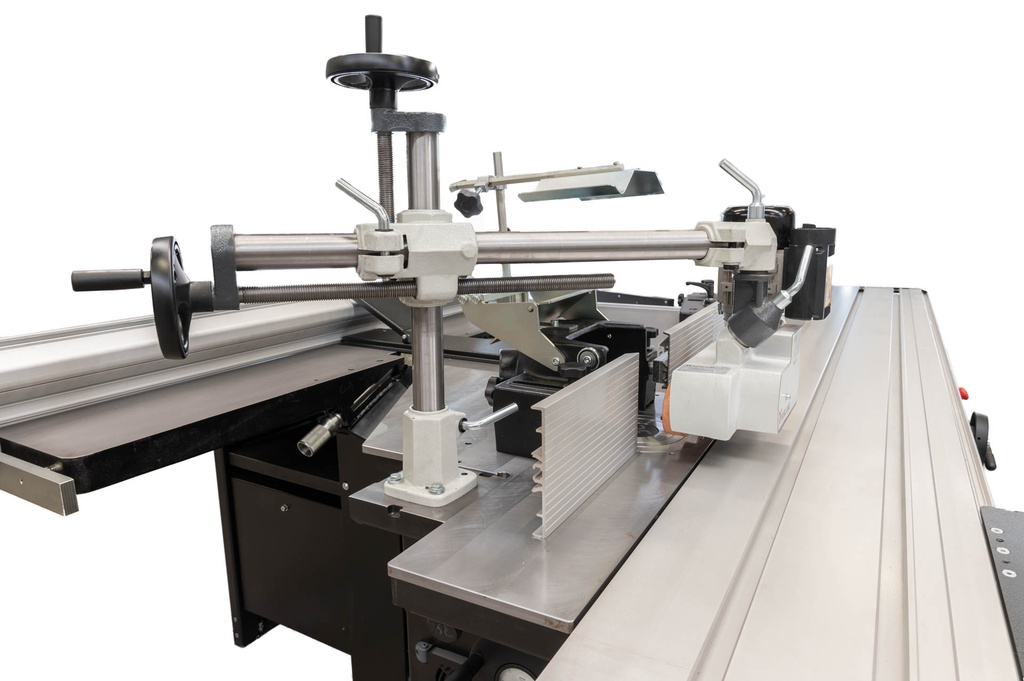

Part of the APEX series, the Xi 410 combines the exceptional quality of a professional panel saw with the versatility of a combined machine.

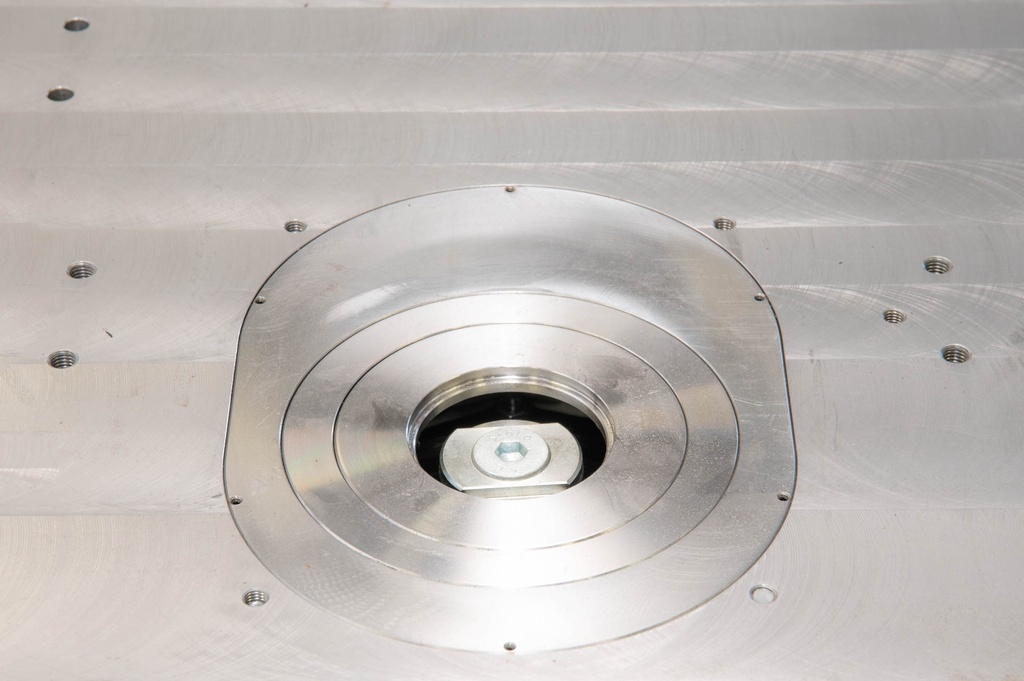

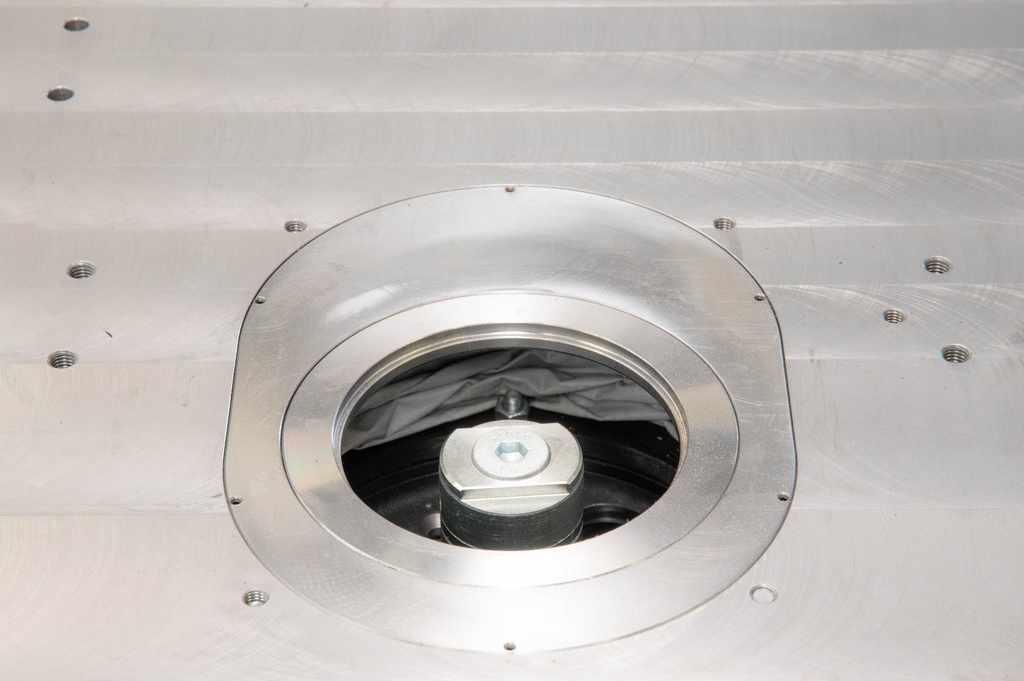

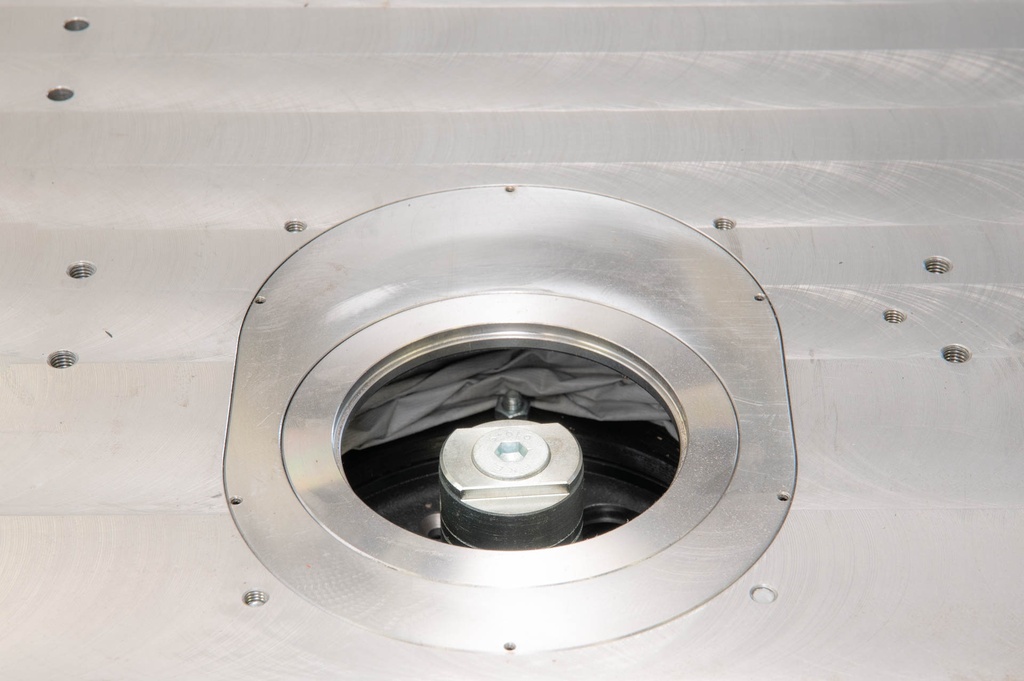

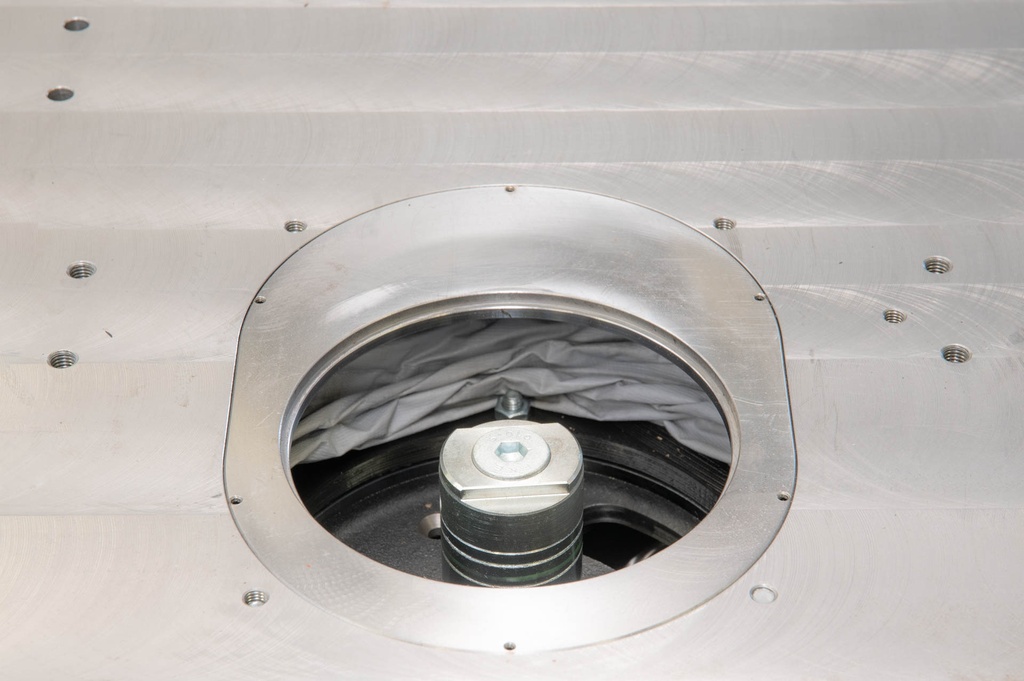

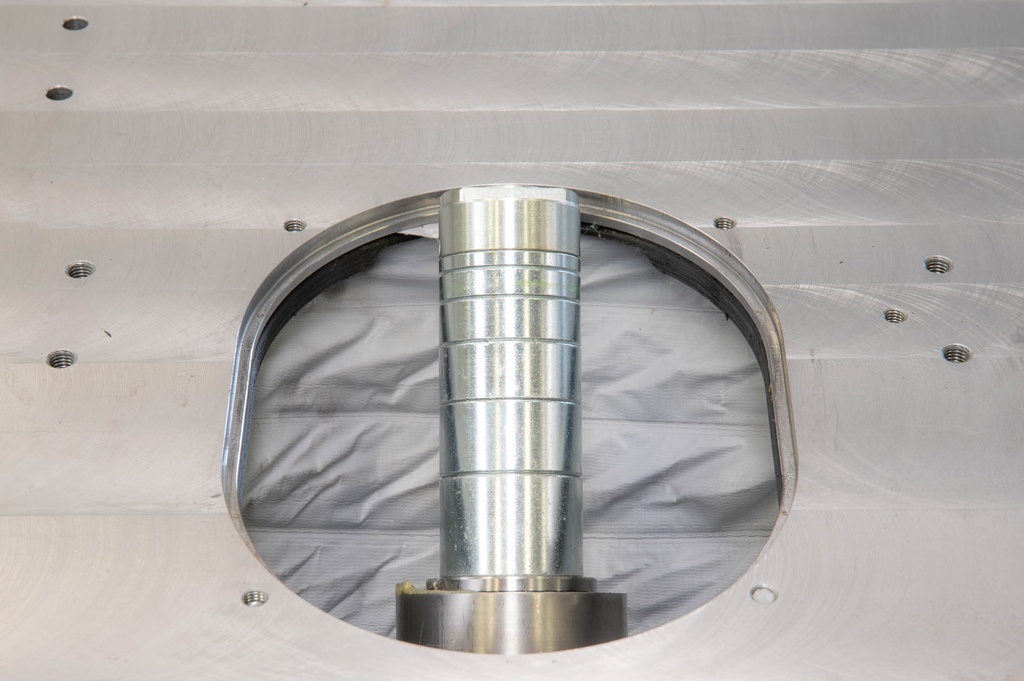

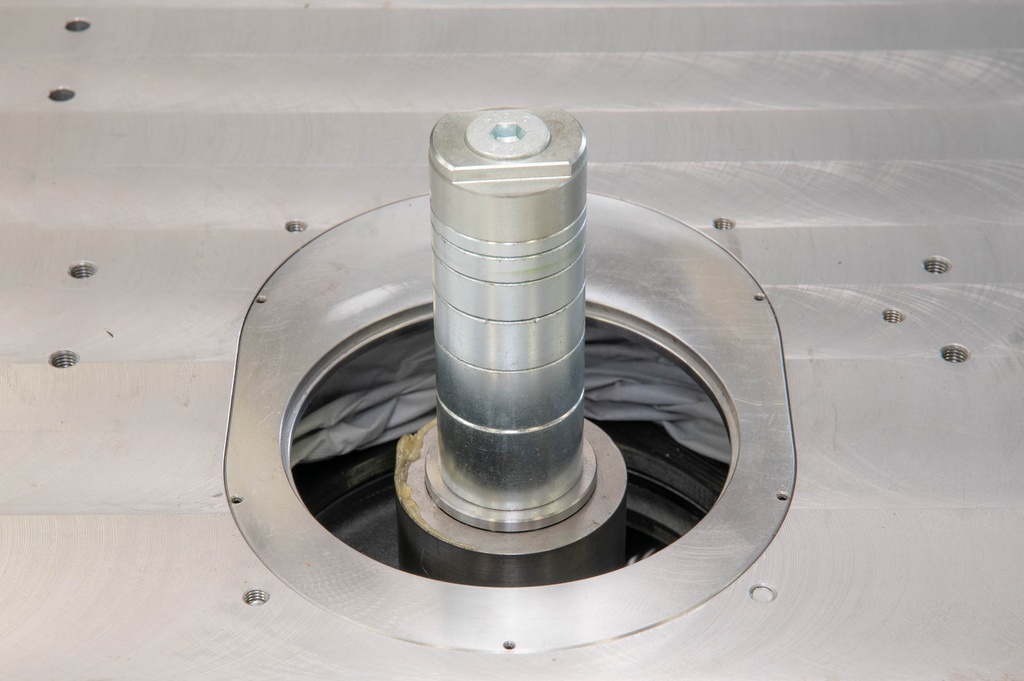

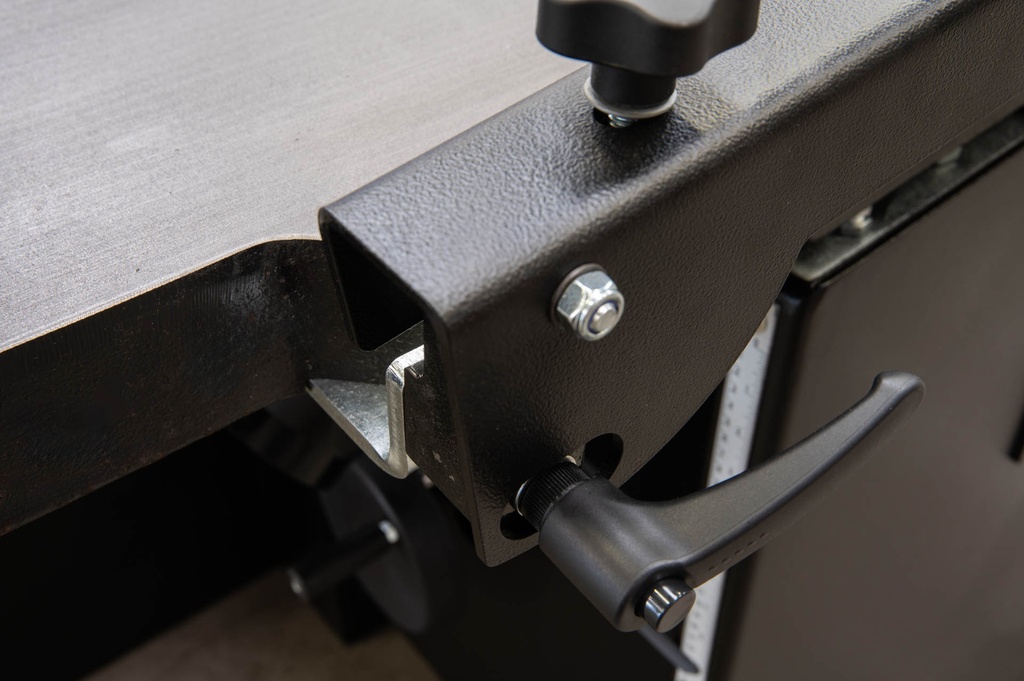

A key upgrade is the steel saw aggregate, borrowed directly from our panel saws, thanks to the shared frame design. This latest saw aggregate incorporates all the advancements from previous models. With a 30mm saw axis and a larger saw flange, the Xi 410 provides superior stability and precision, resulting in dramatically improved cuts.

For added flexibility, the scoring unit is available as an option, recognizing that not everyone will work with full panels. Combined with the ability to upgrade the rip fence and outrigger table, the Xi 410 is an ideal machine for any workshop or woodworking enthusiast, offering unparalleled versatility and performance.

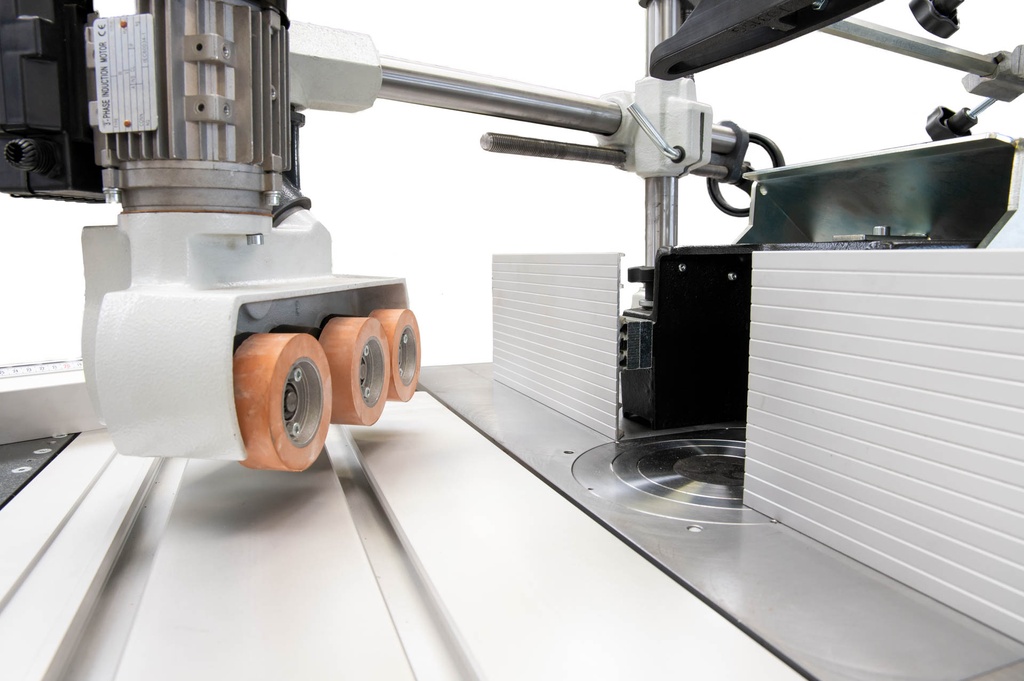

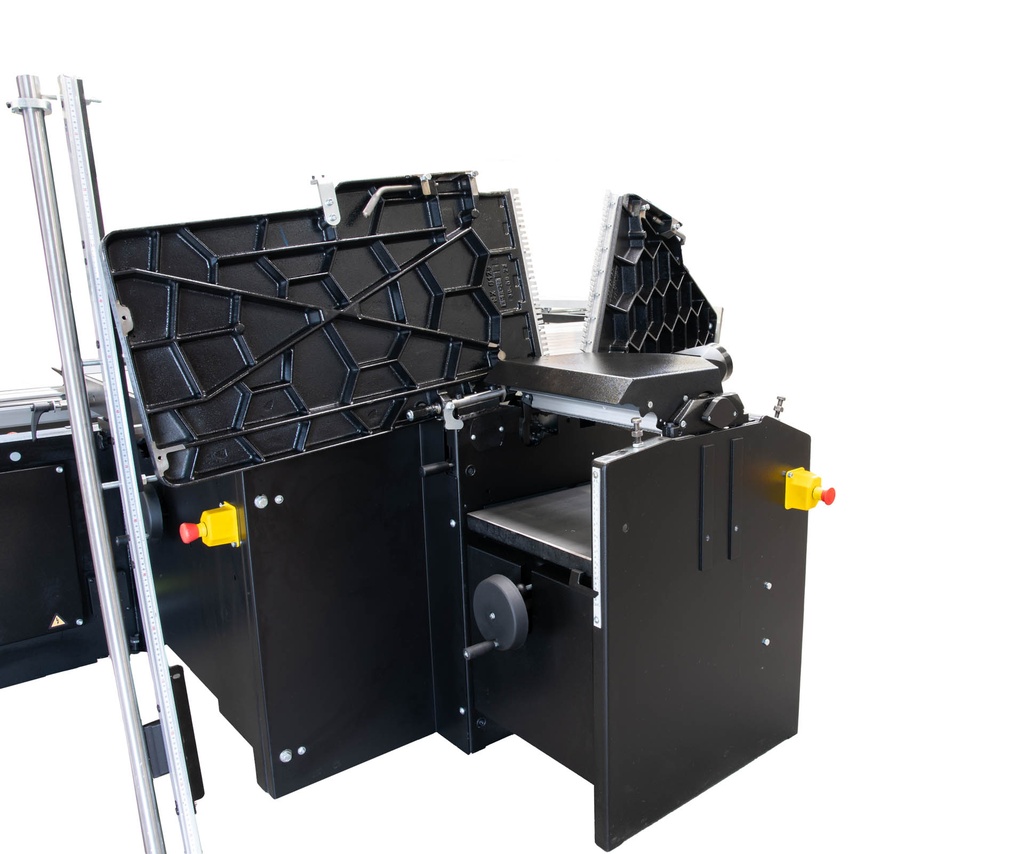

Seamless Multi-Operation Machine

One of the Xi 410’s biggest advantages is how it seamlessly combines multiple operations into one compact machine. This truly is a complete workshop in a single unit. Thanks to Robland’s commitment to innovation and user-friendly design, transitioning between different operations is smooth and efficient. The machine is engineered to minimize re-build time, ensuring that changing from one task to another is quick and hassle-free, allowing you to stay productive with minimal interruptions.

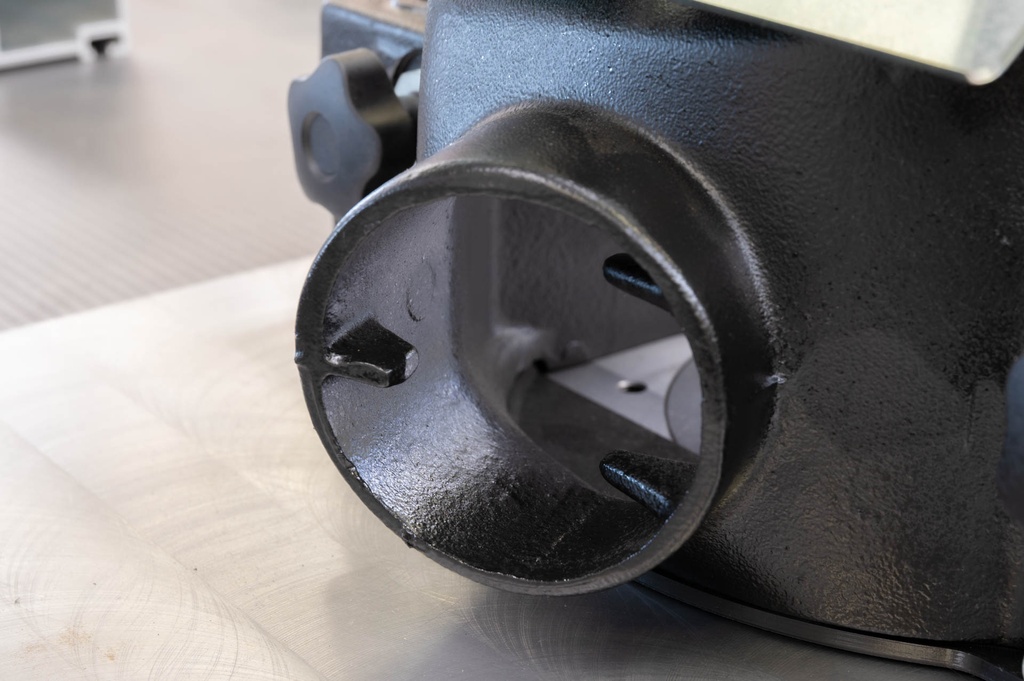

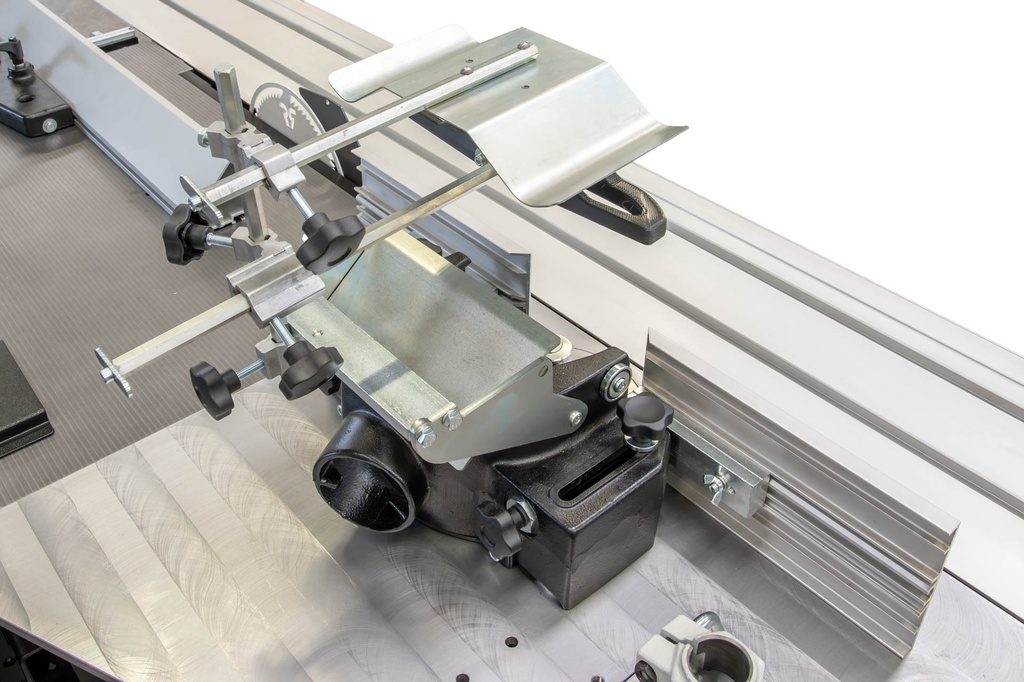

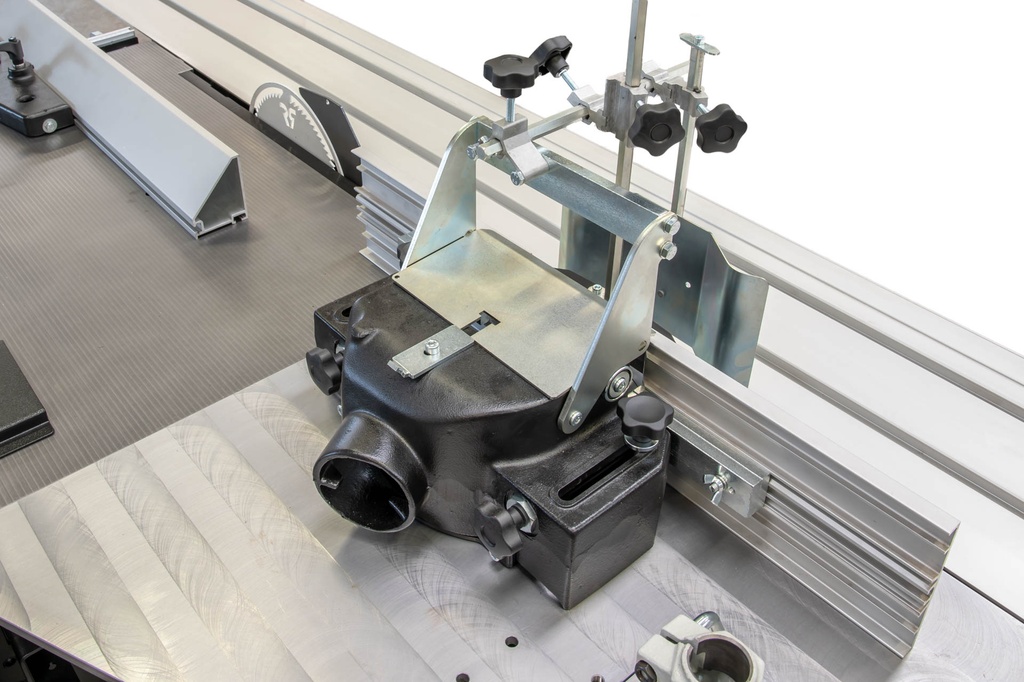

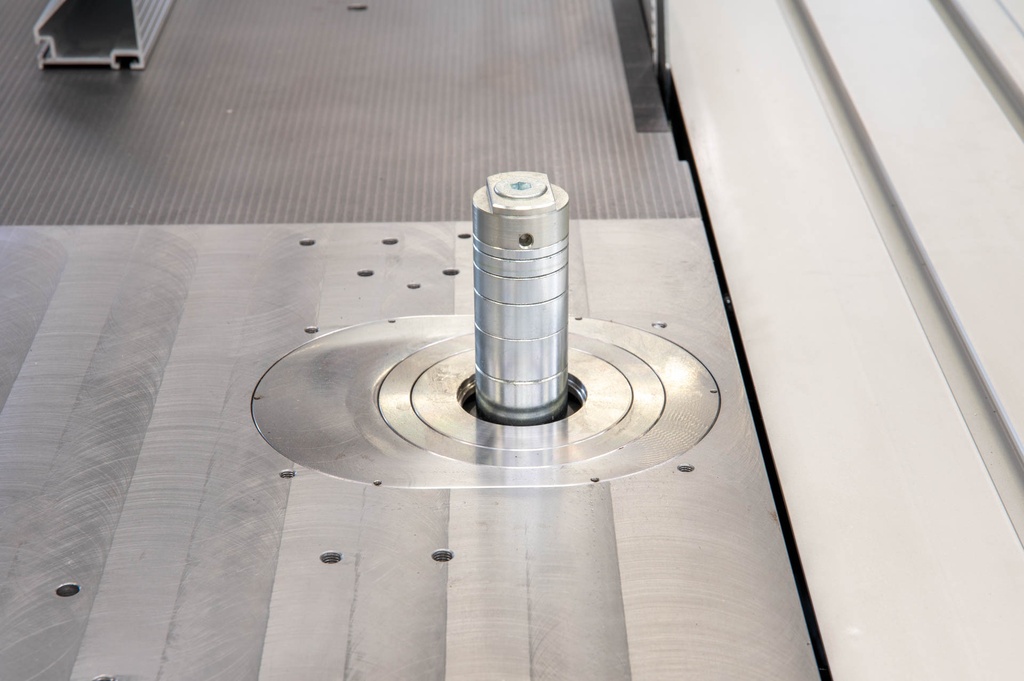

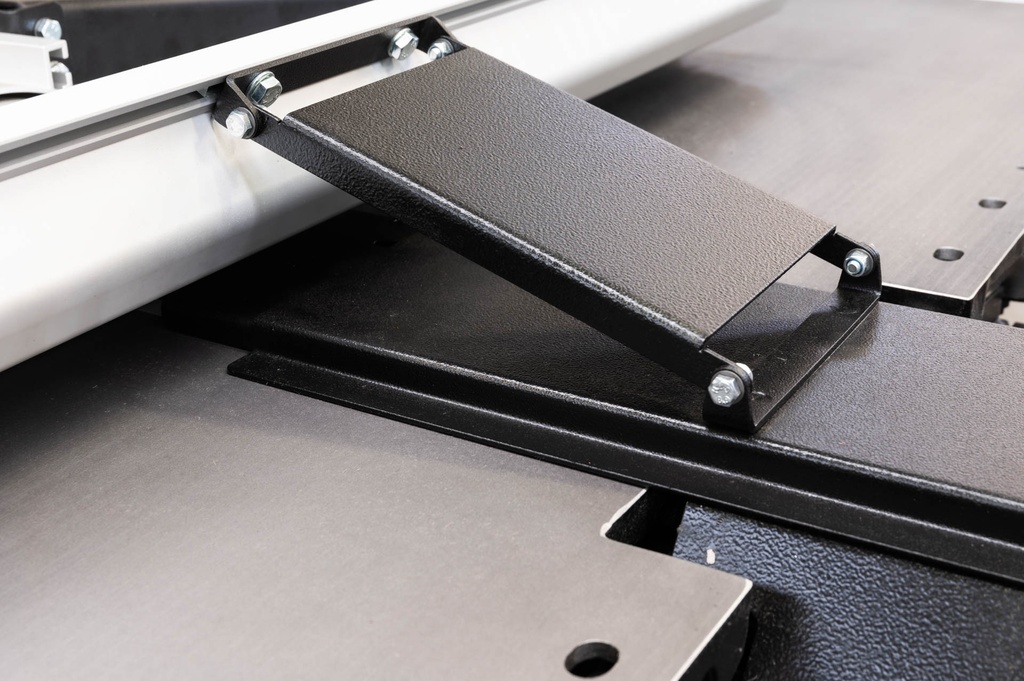

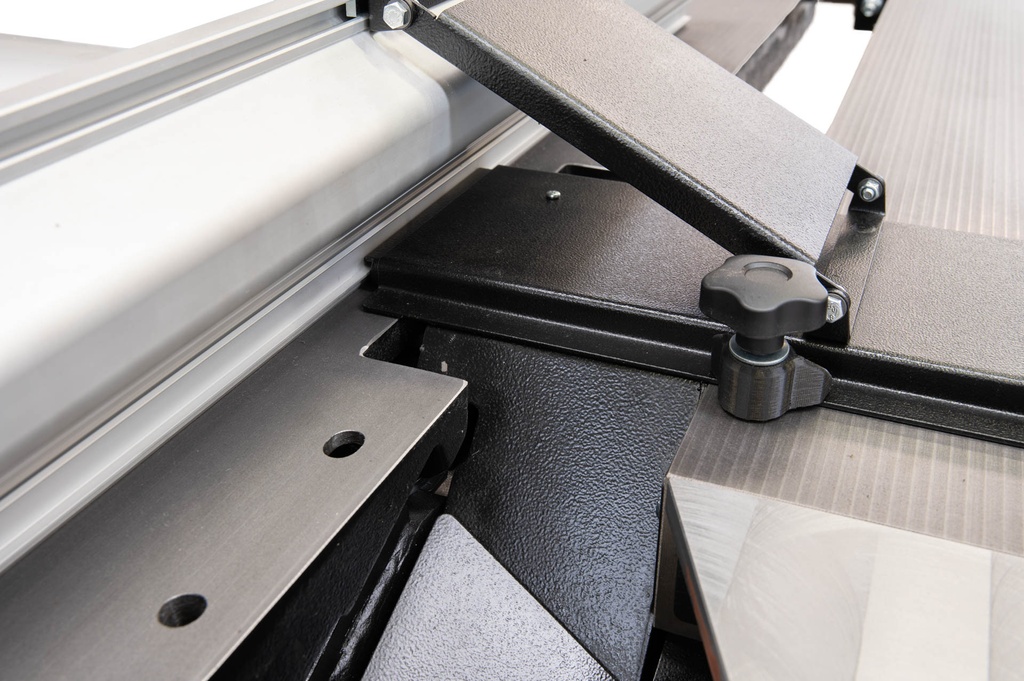

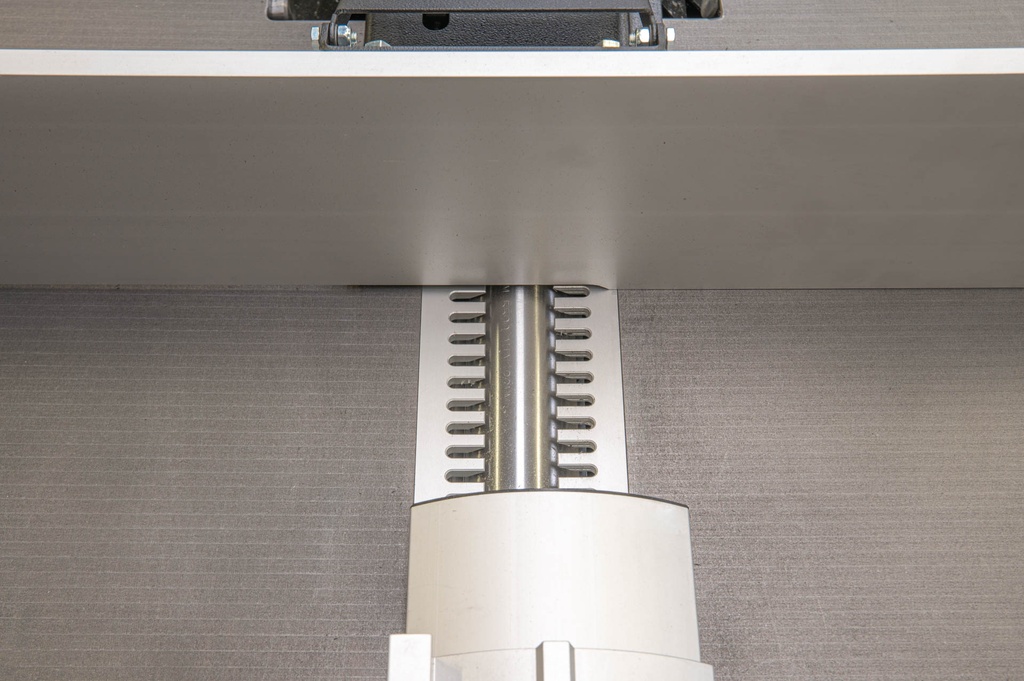

Unmatched Flexibility with Tiltable Spindle

A standout feature of the Xi 410 is the tiltable spindle, now available on our combined machines—a feature previously exclusive to our large T120 series. This innovation brings a new level of flexibility, allowing you to tilt the spindle for more versatile tool use and complex cuts. By incorporating this cutting-edge feature, the Xi 410 combines all the technical advancements of our high-end machines, offering unparalleled precision and versatility in one compact system.

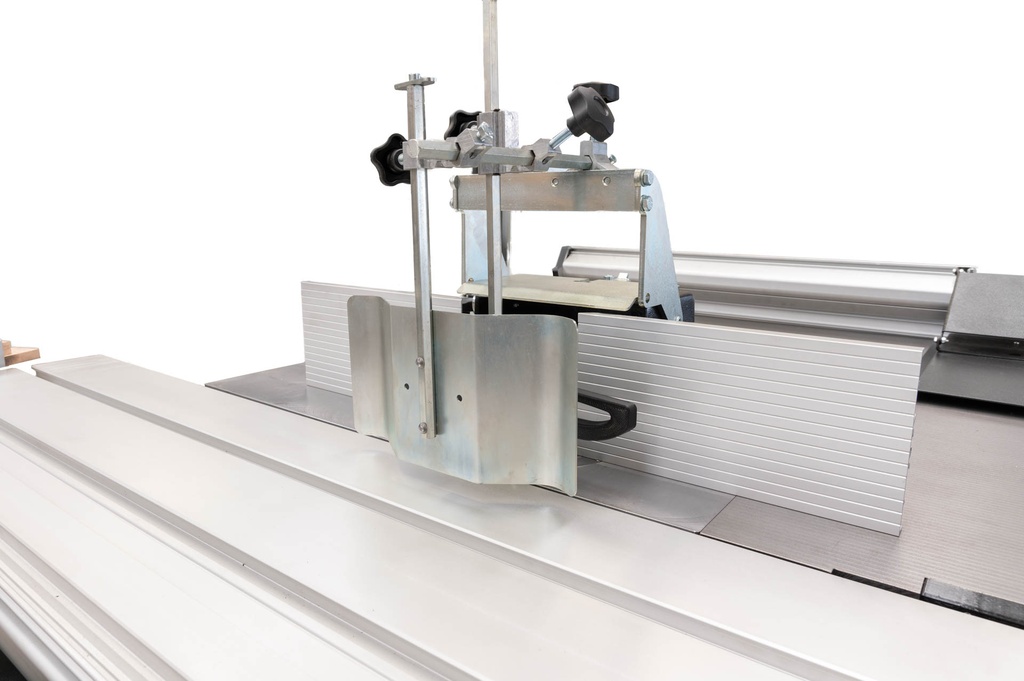

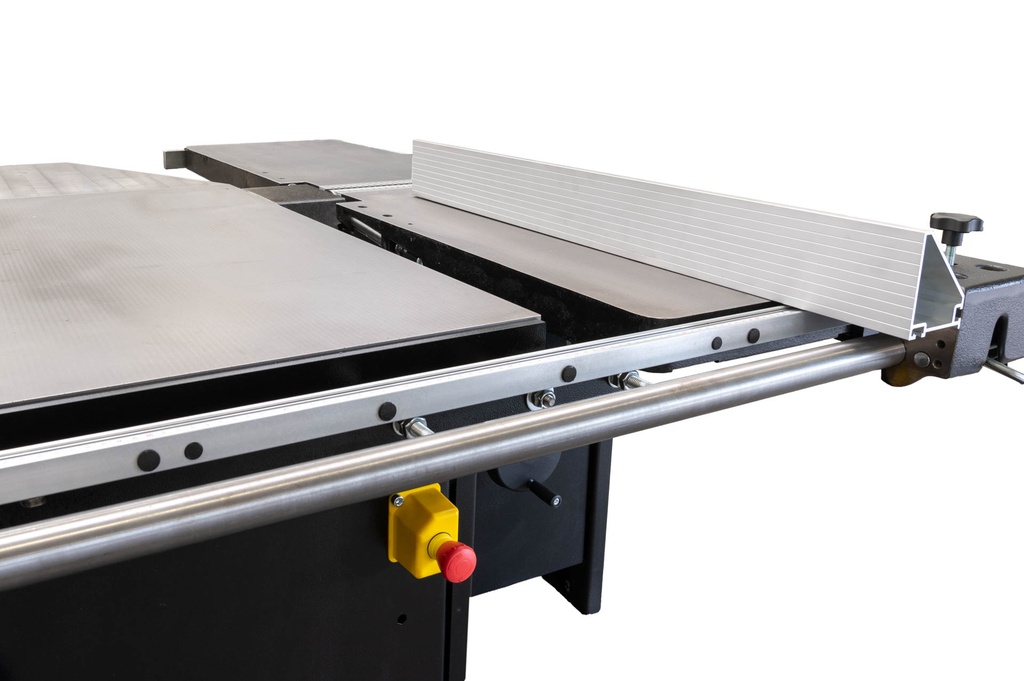

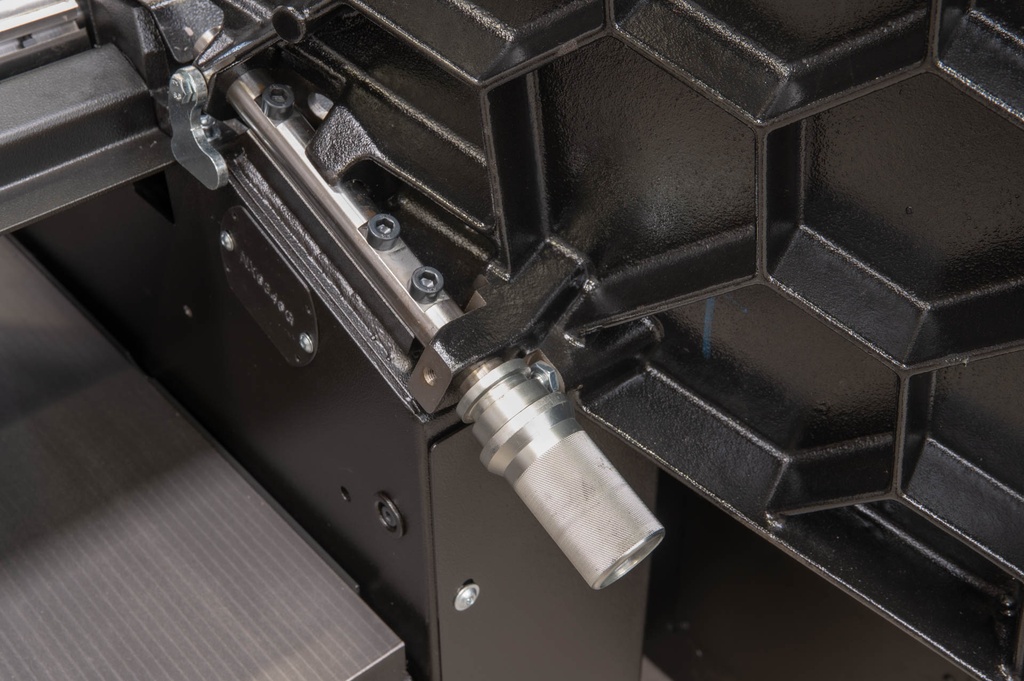

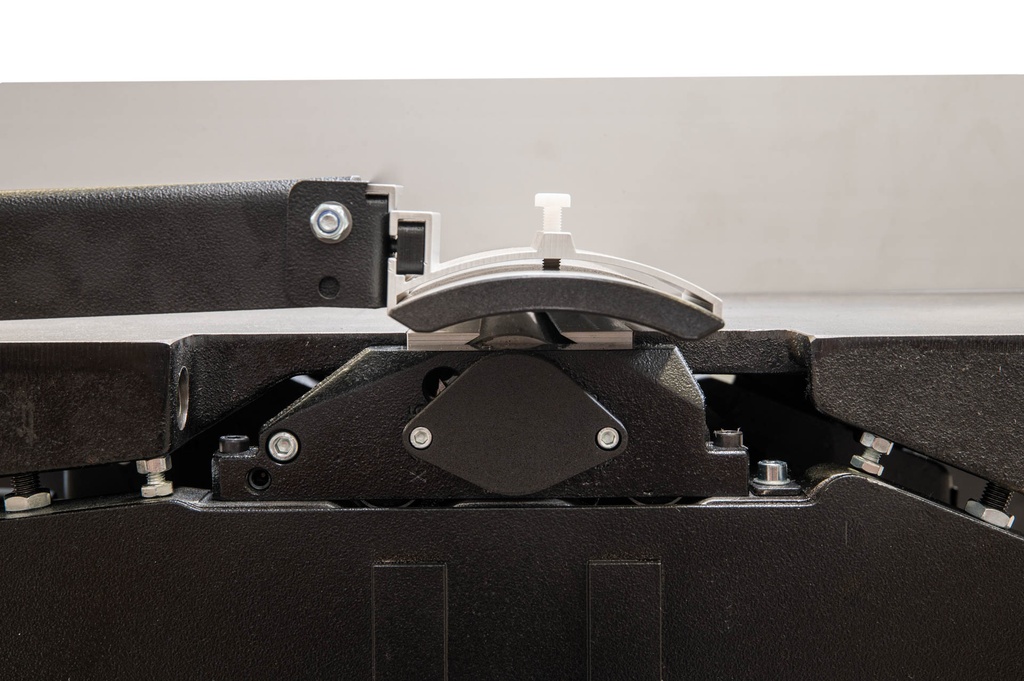

Remote Control in Sliding Table

Another of the standout features is the integrated remote control in the sliding table, a first for combined machines. This innovation allows you to start the machine directly from the sliding table, giving you precise control over when the machine begins operation.

The ability to start the machine exactly when needed, rather than powering it on beforehand, helps to improve workflow efficiency and reduce idle time. It not only saves energy but also enhances safety by allowing you to focus on the task at hand, starting the machine only when you're ready to work.

This remote control feature is designed to streamline your woodworking process, making the machine even more convenient and user-friendly for demanding tasks.

SPECIFICATIONS

General specifications

Saw dimensions

Spindle

Planer-Thicknesser

Mortiser (Optional)

SPEED

Fast Belgian production with trusted European suppliers.

Focus on time and quality instead of costs.

Short supply chain reduces wait times and boosts efficiency.

SUSTAINABILITY

Lifetime spare parts

Responsible production for minimal environmental impact.

Focus on robust, reliable components

SIMPLICITY

User-friendly designs promoting efficiency.

Simple controls with a clear interface ensure smooth operation without unnecessary features.

Easy assembly and maintenance